Manufacturing method of LED lamp and LED lamp

A technology of LED lamp and manufacturing method, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of LED wafer arrangement or shape limitation, uneven light, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

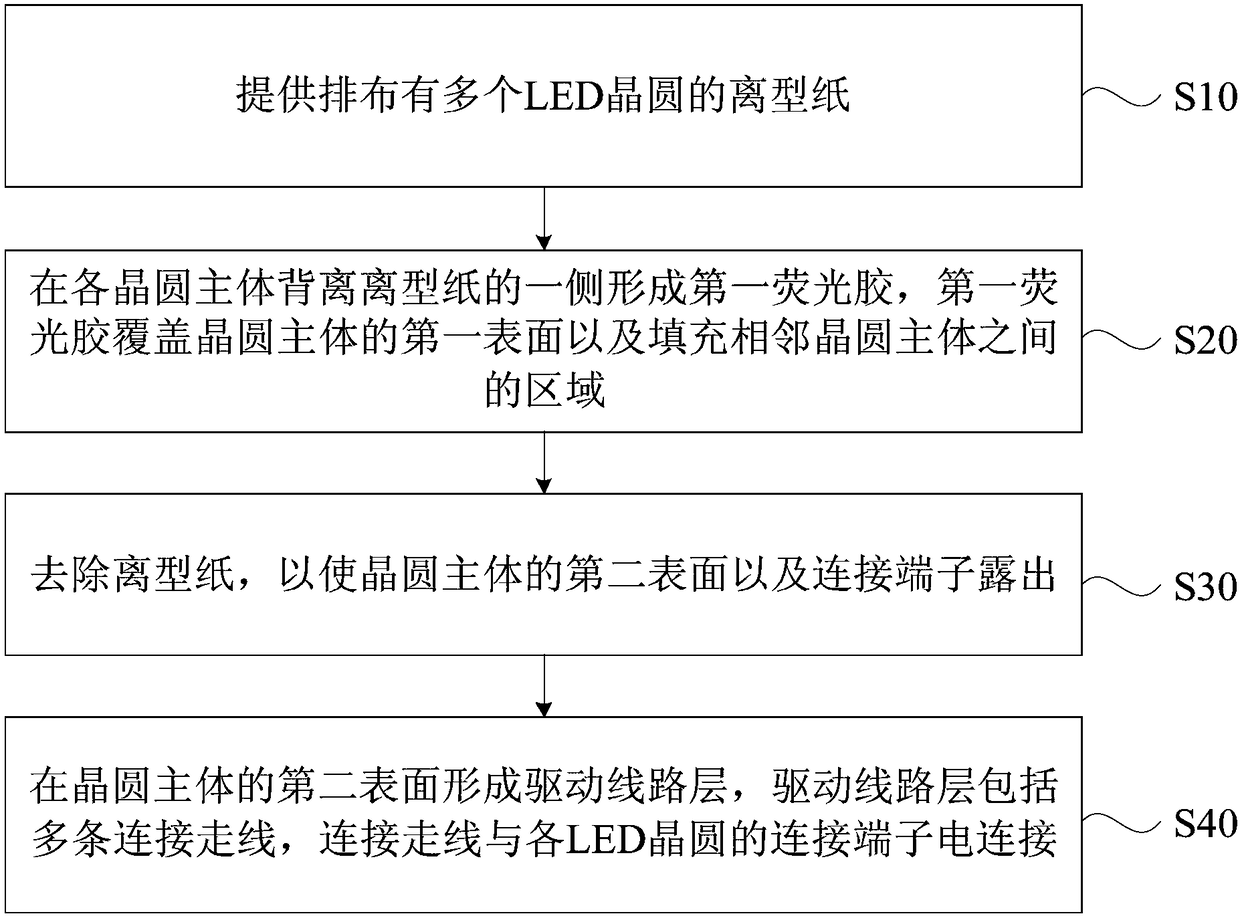

[0042] figure 2 It is a method for manufacturing an LED lamp provided in Embodiment 1 of the present invention. Figure 3-Figure 6 is to use figure 2 The LED light manufacturing method provided in the LED light is a structural schematic diagram of each state of the LED light when making an LED light. see figure 2 and Figure 3-Figure 6 , the manufacturing method of the LED lamp, comprising:

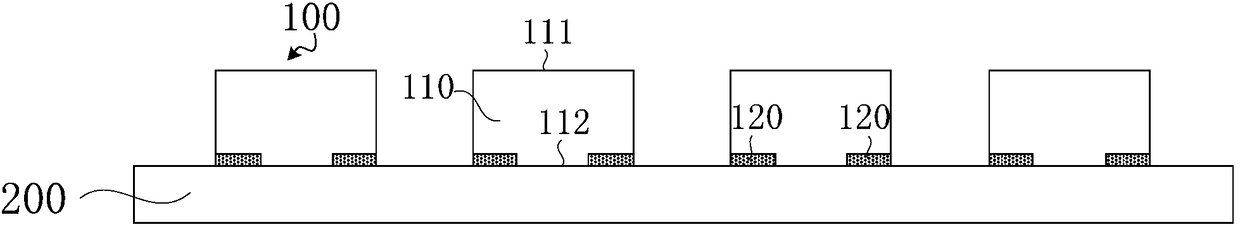

[0043] S10, providing a release paper on which a plurality of LED wafers are arranged.

[0044] see image 3 , providing a release paper 200 on which a plurality of LED wafers 100 are arranged. The LED wafer 100 includes a wafer body 110 and at least two connection terminals 120. The surface of the wafer body 110 away from the release paper 200 is the first surface 111, and the surface of the wafer body 110 close to the release paper 200 is the second surface 112. , at least two connection terminals 120 are disposed on the second surface 112 of the wafer body 110 and are electri...

Embodiment 2

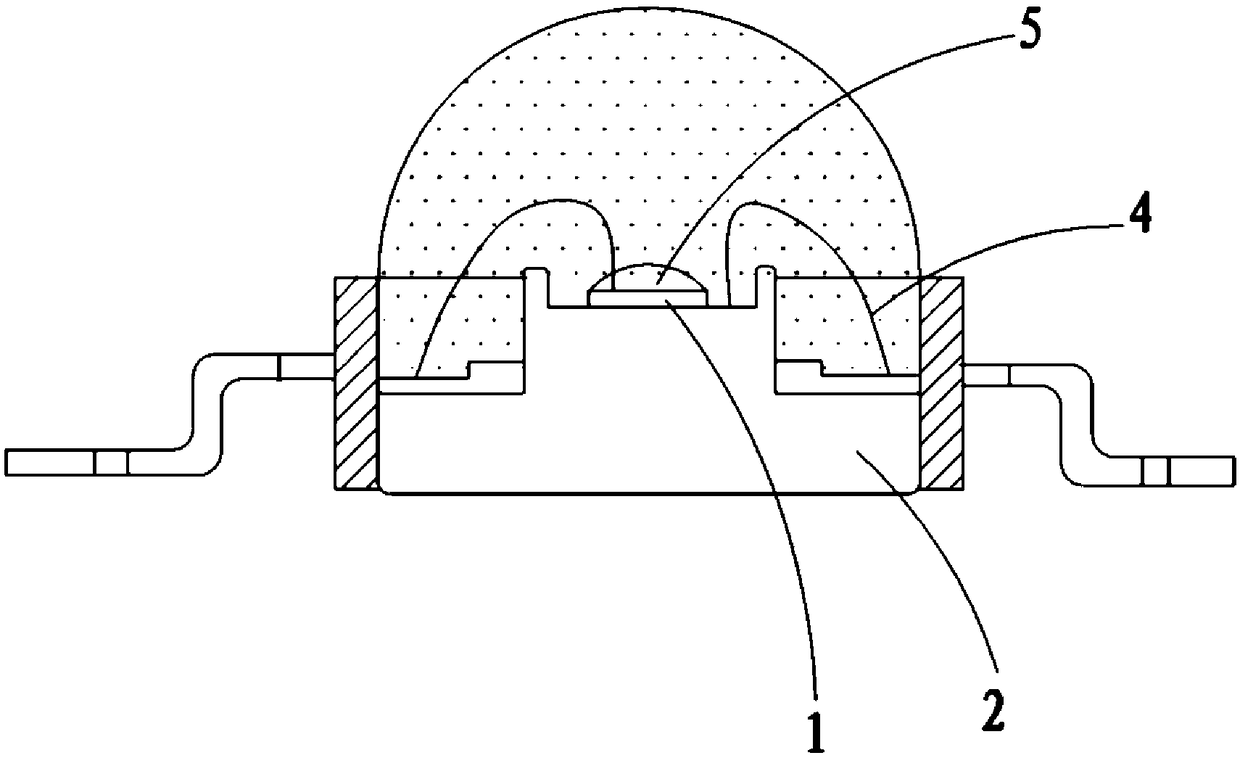

[0064] The embodiment of the present invention also provides an LED lamp, which can be manufactured by using any one of the manufacturing methods of the LED lamp in the above-mentioned embodiments. Figure 7 It is a schematic structural diagram of an LED lamp provided in Embodiment 2 of the present invention. Figure 8 is along Figure 7 Schematic diagram of the cross-sectional structure of A1-A2. see Figure 7 and Figure 8 , the LED lamp 10 includes: a plurality of LED wafers 100, the LED wafer 100 includes a wafer body 110 and at least two connection terminals 120, the wafer body 110 includes a first surface 111 and a second surface 112 oppositely arranged, at least The two connection terminals 120 are arranged on the second surface 112 of the wafer body 110 and are electrically insulated from each other; the first fluorescent glue 300 is formed on the side of each wafer body 110 facing away from the second surface 112, and the first fluorescent glue 300 covers The firs...

Embodiment 3

[0068] Figure 9 It is a schematic cross-sectional structure diagram of an LED lamp provided in Embodiment 3 of the present invention. Compared with the second embodiment, in this embodiment, the LED lamp further includes a phosphor layer. see Figure 9 The phosphor layer 500 is located between the first phosphor glue 300 and the wafer body 110 , covering the first surface 111 of the wafer body 110 and the side surface 113 intersecting the first surface 111 and the second surface 112 . This setting can make the light emitted by the LED wafer 100 pass through the phosphor layer 500 first, and the phosphor layer 500 can initially solidify the color temperature and brightness of various angles, so that the light emitted by the wafer body 110 is more uniform, and avoid the LED wafer. The phenomenon of non-uniform luminescence caused by only covering the first fluorescent glue 300 on the side of the 100 away from the second surface 112 occurs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com