Tail puller positioning structure and linear actuator

A positioning structure and positioning surface technology, applied in the direction of electric components, control mechanical energy, electrical components, etc., can solve problems such as troubles, achieve stable positioning effect, long positioning life, and stable assembly relationship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

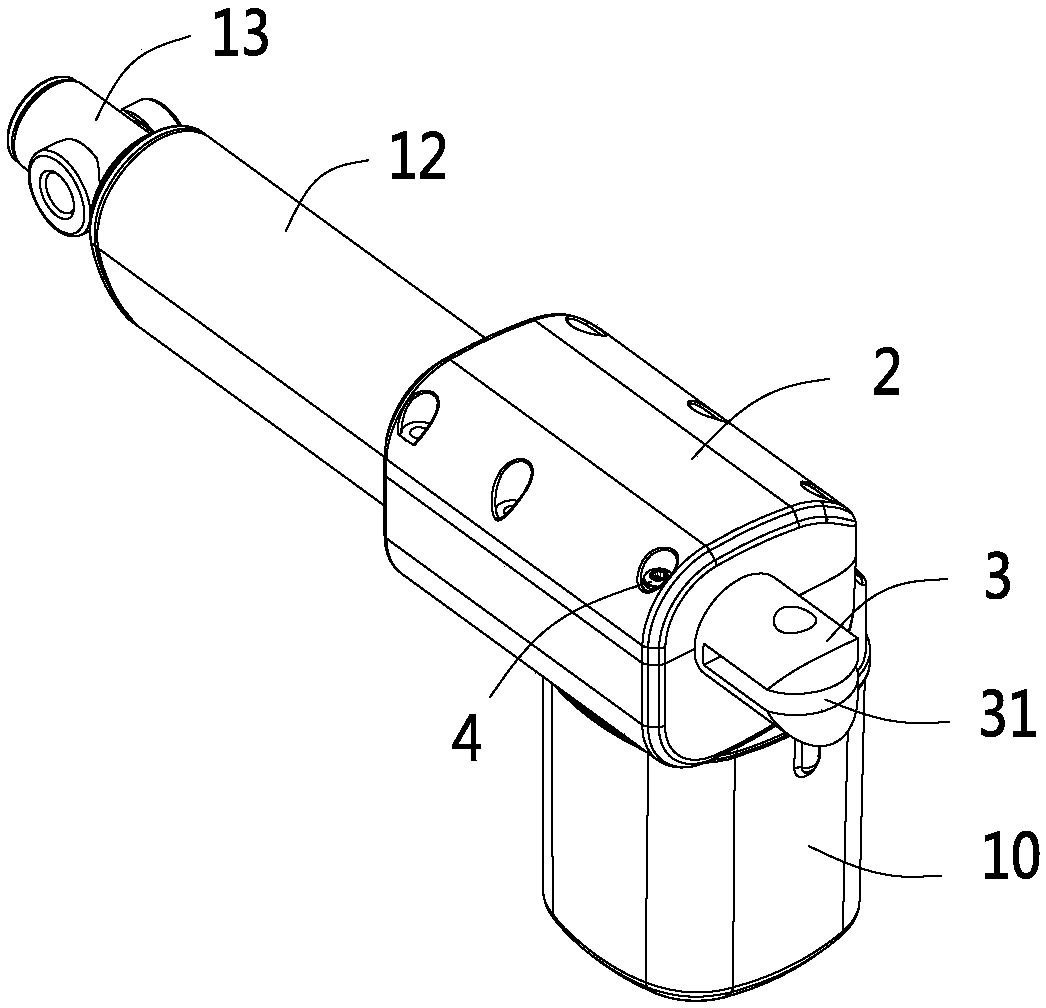

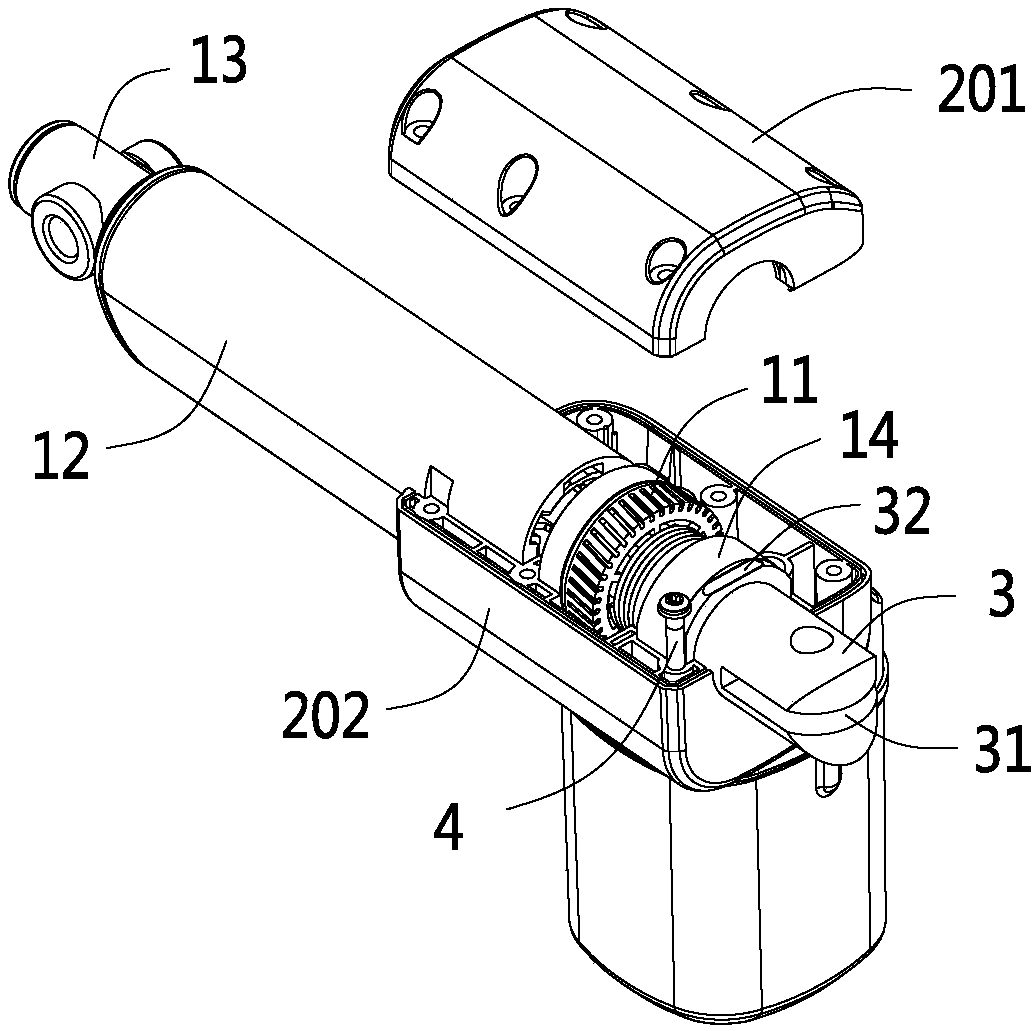

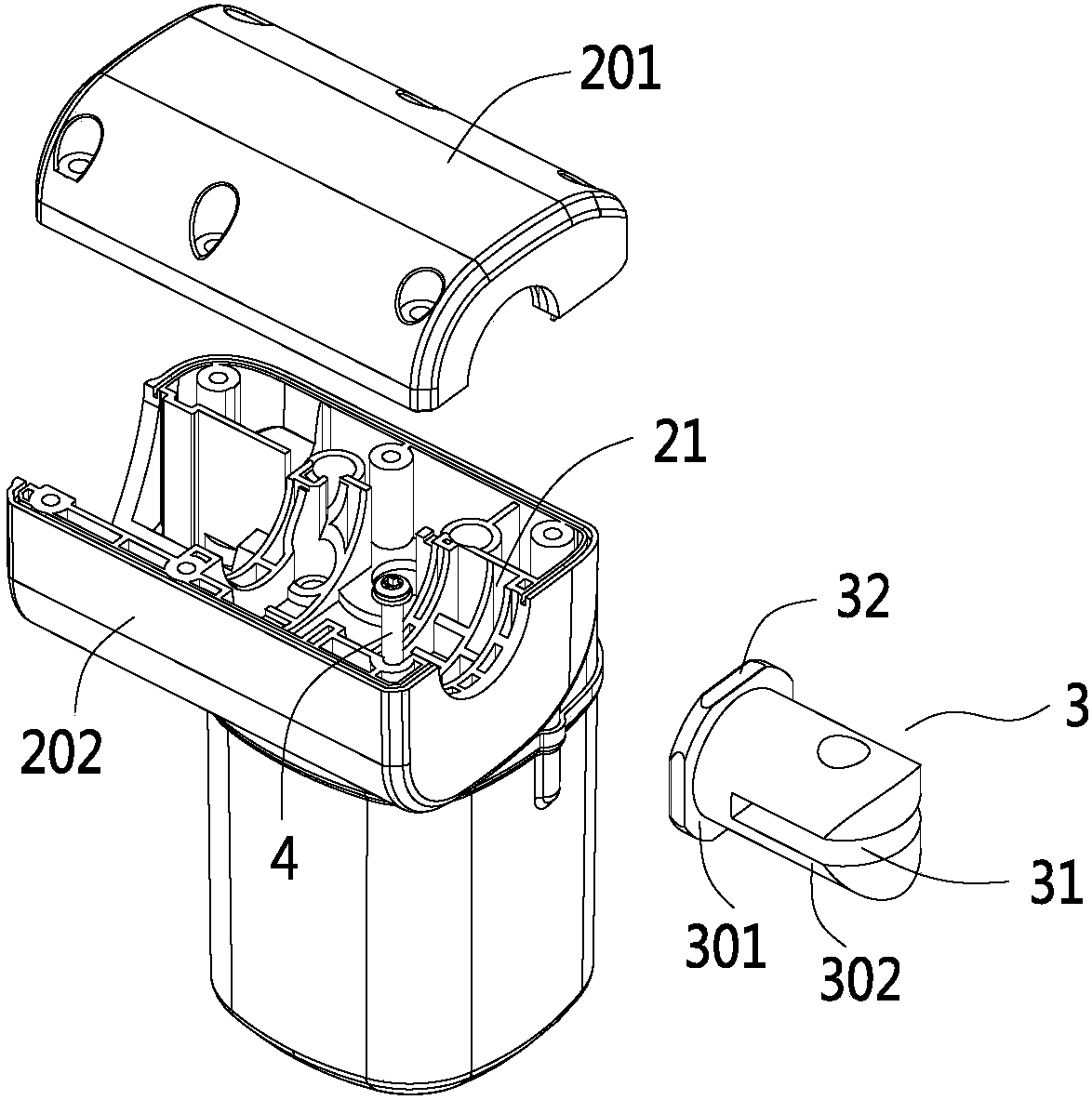

[0030] Such as Figure 1 to Figure 4 As shown, the present embodiment is a linear actuator. The linear actuator in the present embodiment includes a drive motor 10, a drive worm, a worm wheel 11, a screw, and a nut. The drive motor 10 is connected to the drive worm, and the drive worm drives the worm wheel 11 to rotate. , the rotation of the worm wheel 11 drives the screw to rotate, and the rotation of the screw drives the nut to move axially. In addition, this embodiment also includes a shell 2, an outer tube 12, and an inner tube 13. The outer shell 2 is connected to the outer tube 12, and the nut is connected to the inner tube 13 connection, the axial movement of the nut is finally expressed as the axial relative displacement between the inner tube 13 and the outer tube 12 .

[0031] The linear actuator in this embodiment also includes a tail pull 3, which is provided with a mounting groove 31 for fixing the driven object, and the tail pull 3 is connected with the shell 2 a...

Embodiment 2

[0044] The difference between this embodiment and Embodiment 1 is that the positioning column used to match the positioning surface is not a fastening screw, as for the fastening piece that fixes the first shell and the second shell, it can still be a fastening screw Or other buckle structure.

[0045] The positioning column in this embodiment is a positioning pin, and the positioning pin is inserted into the embedded groove in a plug-in manner. In order to prevent the positioning pin from detaching from the embedded groove, it can be fastened with a buckle, for example, in the embedded A buckle groove is arranged in the loading groove, and an elastic buckle or elastic steel ball is arranged in the positioning pin. When the positioning pin is inserted, the elastic buckle or elastic steel ball cooperates with the buckle groove, and the side of the positioning pin fits and matches with the embedded section 301 simultaneously. Locating pins can be cylindrical pins or square pins ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com