A kind of automatic processing method of new energy auto parts

A new energy vehicle and processing method technology, applied in the field of automatic processing of new energy auto parts, can solve the problems of insufficient stability of assembly relationship, inability to meet the requirements of automobile production, and low yield of molded parts, and achieve high level of automatic processing and high product yield. High, high output efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the objects and advantages of the present invention more clear, the present invention will be described in detail below with reference to the embodiments. It should be understood that the following text is only used to describe one or more specific embodiments of the present invention, and does not strictly limit the protection scope of the specific claims of the present invention.

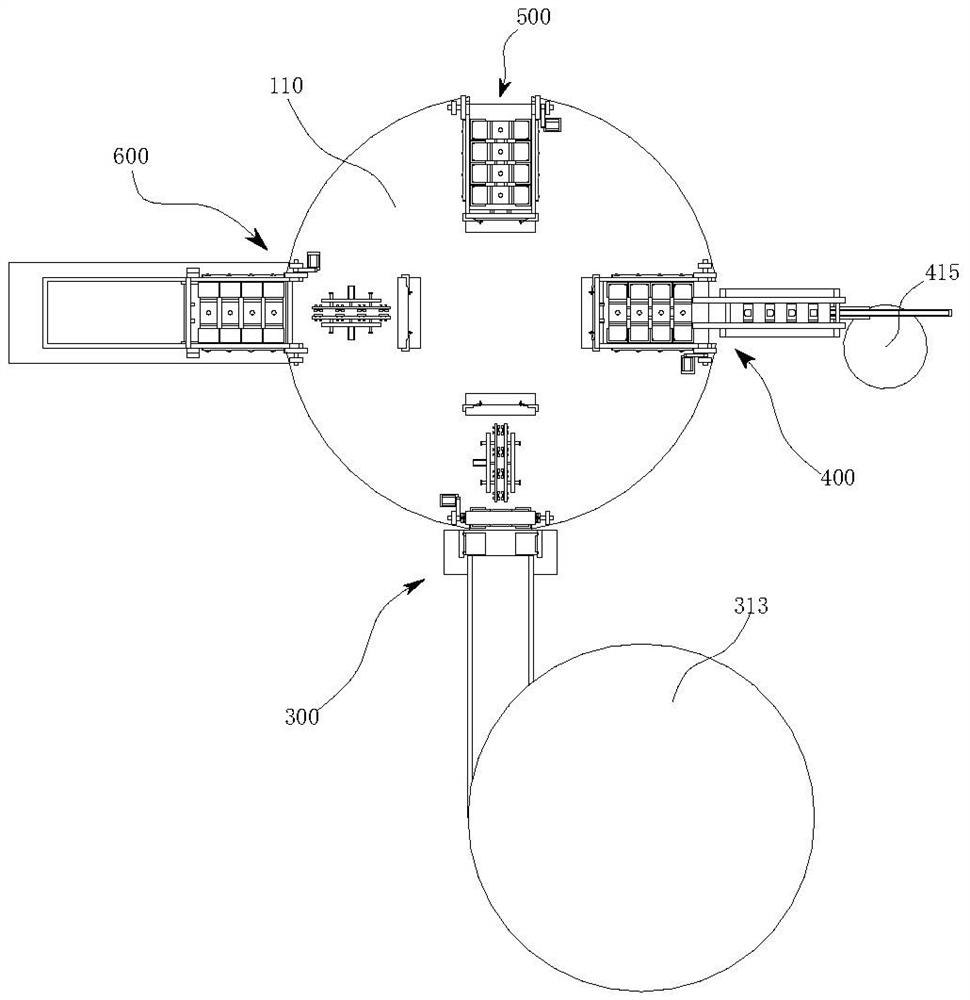

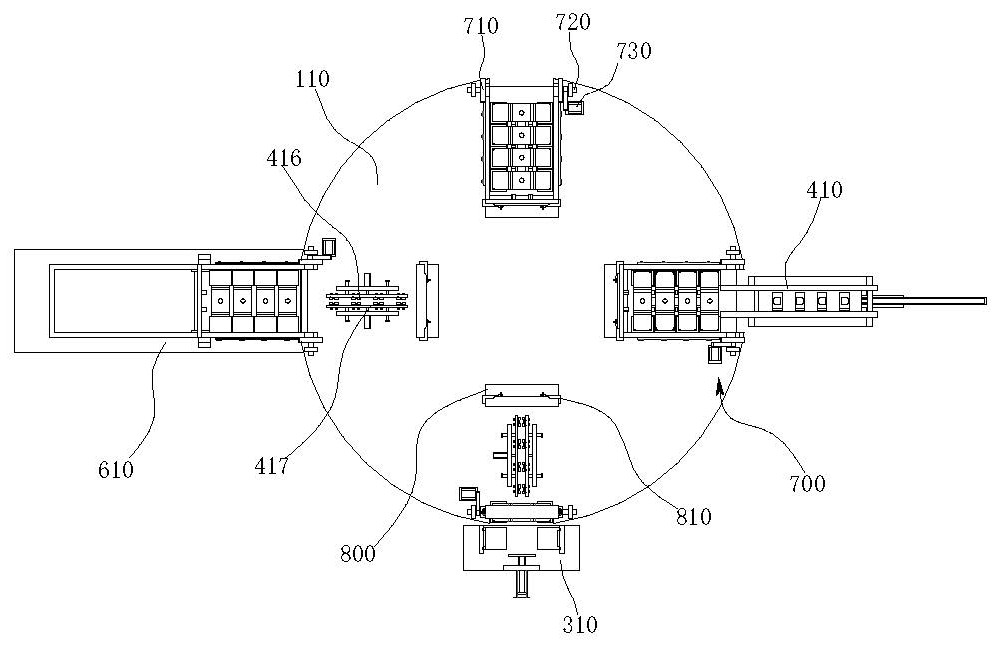

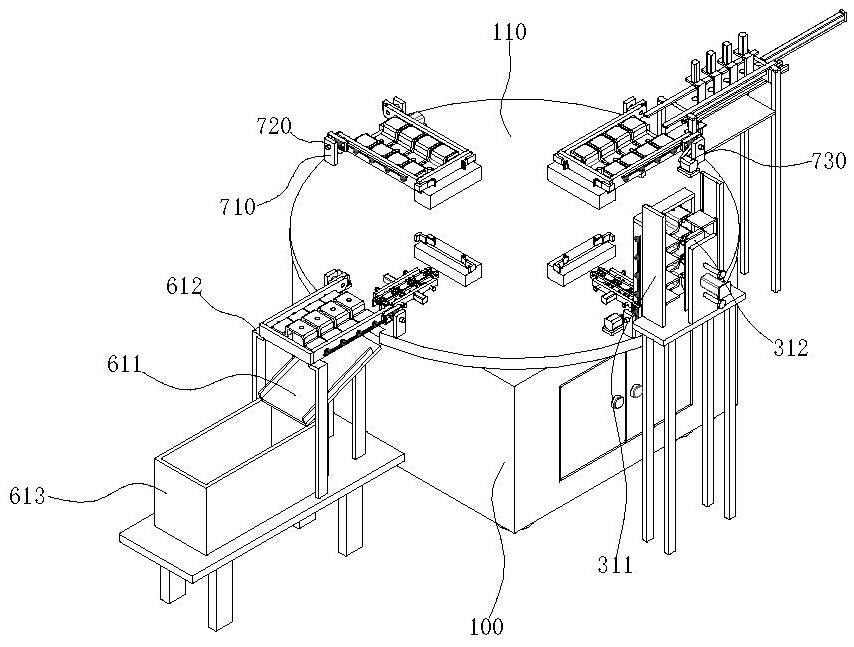

[0041] see Figure 1 to Figure 16 , the embodiment of the present application proposes an automatic processing equipment for auto parts, which aims to solve the low efficiency of the manual assembly method used to produce this type of parts in the prior art, and it is impossible to form multiple parts at one time during assembly, and the production effect cannot be obtained. Guarantee, etc.

[0042] like Figure 1 to Figure 16 As shown, the technical solution of the embodiment of the present application is an automatic processing equipment for auto parts, including a work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com