A glass fiber reinforced plastic profile composite floating raft

A technology of reinforced plastic and glass fiber, applied in rafts, floating bridges, bridges, etc., can solve the problems of inconvenient transportation, can not withstand the impact of wind and waves, and the splicing method is not strong enough, and achieve the effect of increasing the weight of the bottom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

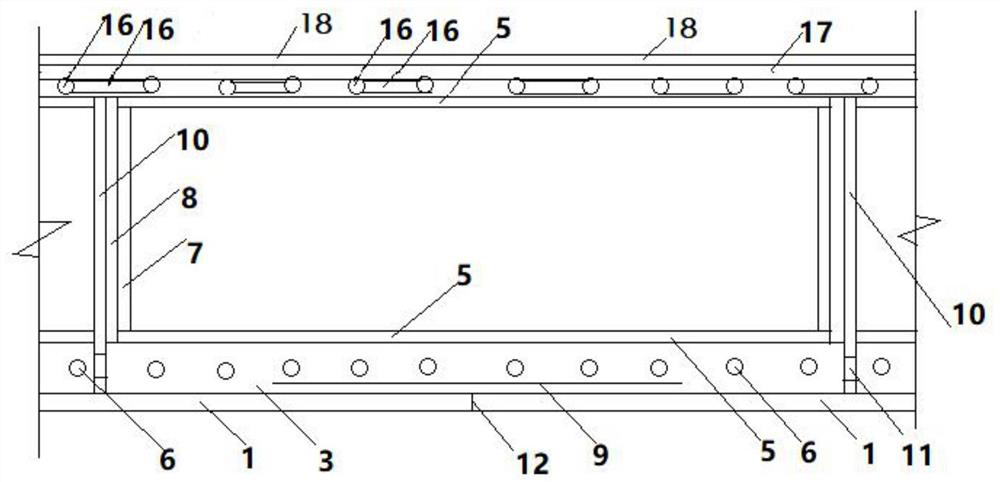

Embodiment 1

[0016] (1) Drill holes on the U-shaped pultrusion profile

[0017] U-shaped profile 1 of glass fiber reinforced plastic (FRP) is produced by pultrusion molding (the minimum width of U-shaped profile 1 is 300mm), and two rows of holes of equal diameter are drilled on the upper and lower sides of the two flanges of 1, and the axis of the hole 20-30mm from the outer side of the web (lower side of the U-shaped profile 1). The upper row of holes is evenly distributed along the longitudinal direction of the flange of the U-shaped profile (perpendicular to the cross-sectional direction), and the hole distance is 150-300mm. The axis of the lower row of holes is 15-20mm away from the edge of the flange (the top surface of the U-shaped profile 1).

[0018] (2) Pierce the lower row of FRP bars through the holes first, and then pour concrete into the inner bottom of the U-shaped bar

[0019] Place the U-profiles 1 side by side in flat shallow water, and align the two rows of holes. Firs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com