Polymer thrust bearing

A technology of thrust bearings and polymers, applied in bearings, bearing assemblies, bearing components, etc., can solve problems such as inability to accurately reflect the operating temperature of bearings, and achieve the effect of real-time accurate bearing temperature and working status

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The polymer thrust bearing provided by the present invention will be further described in detail and completely below in conjunction with the examples. The embodiments described below are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

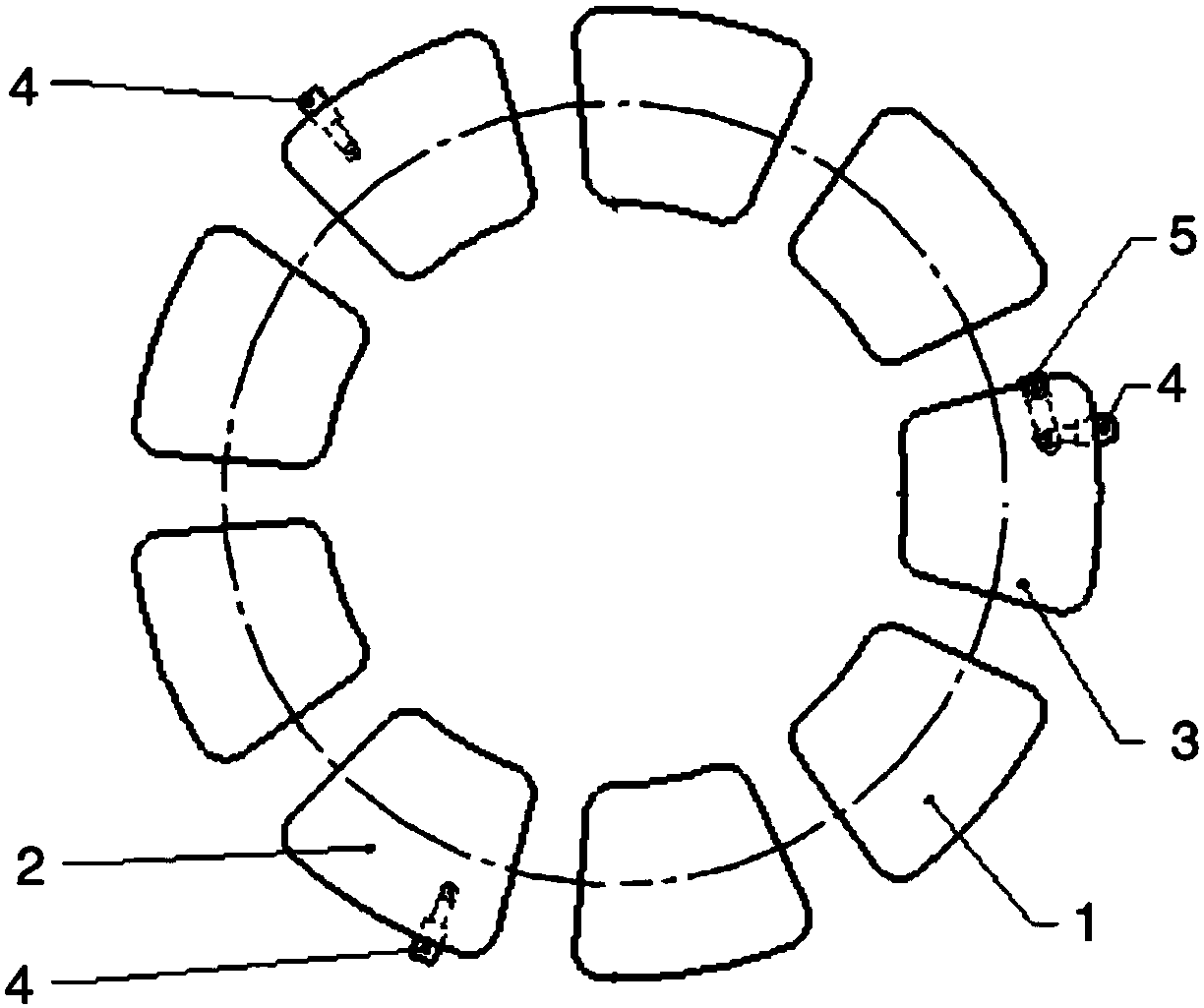

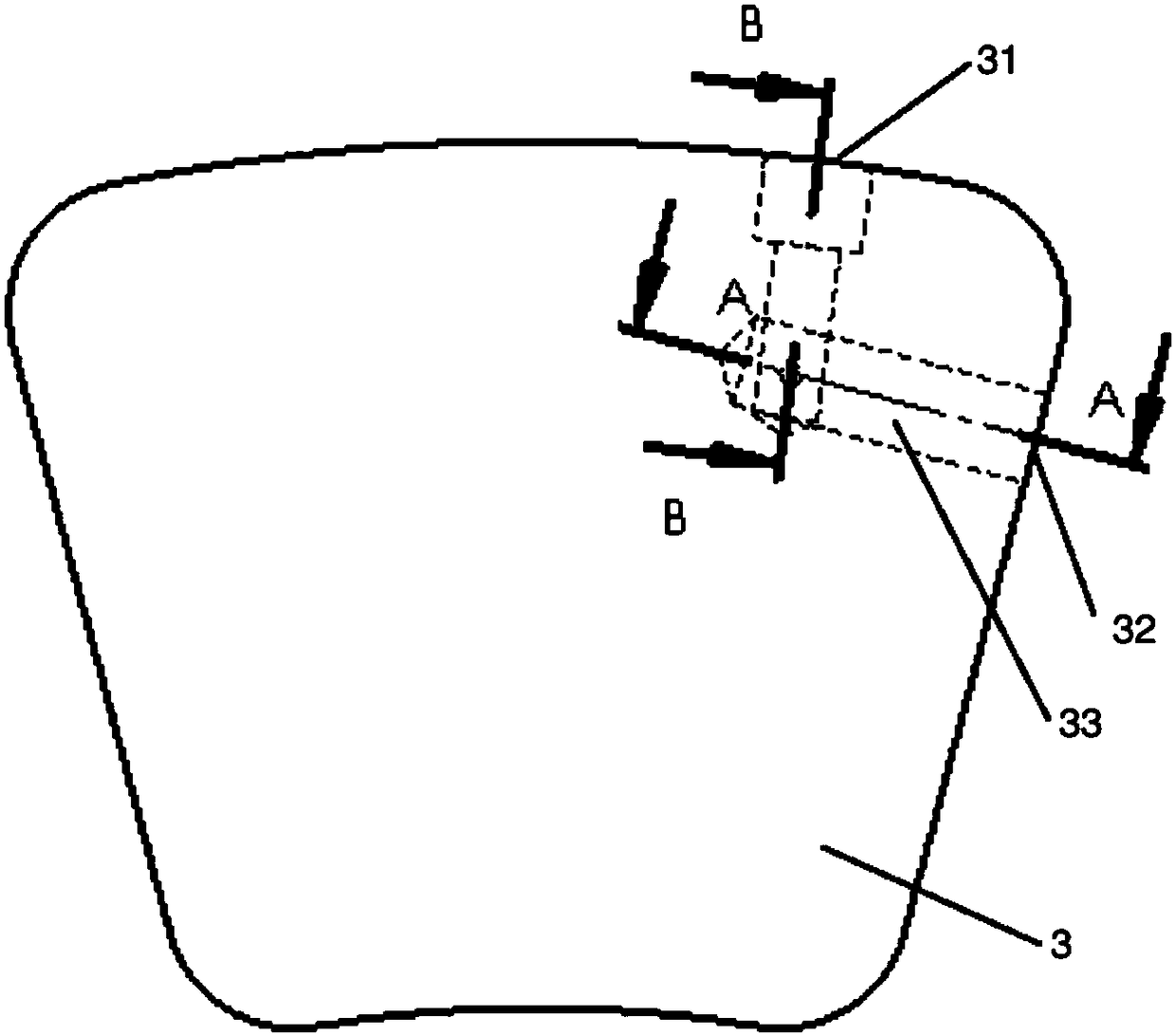

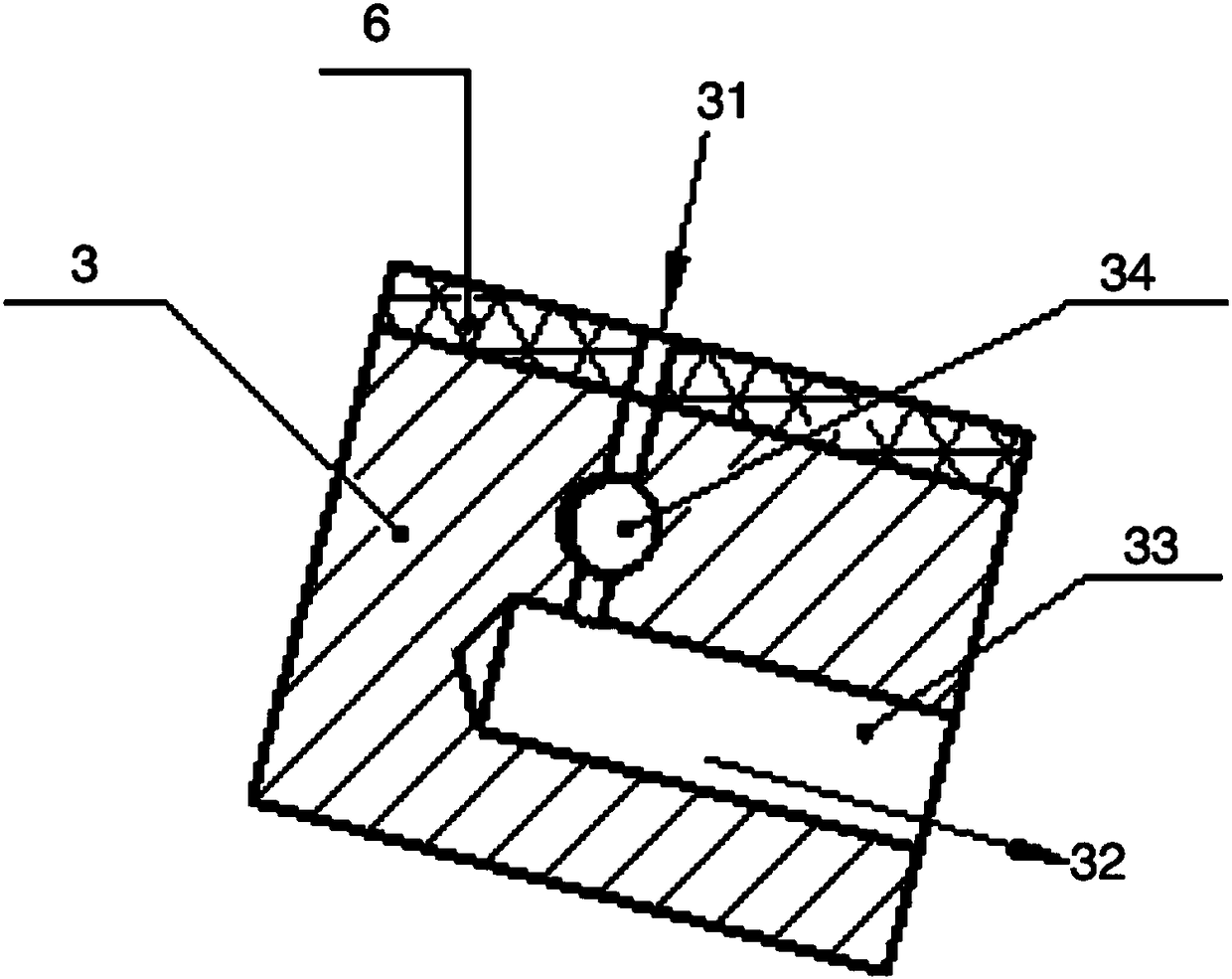

[0037] Such as Figure 1-7 In the polymer thrust bearing, the polymer thrust bearing has thrust pads of three structures, the first type is a first thrust pad 1 of a common structure, and the second type is a second thrust pad 2 with a temperature measuring element 4 , the third type is the third thrust pad 3 with oil through hole 31, oil outlet hole 32, flow guide channel 33 and temperature measuring element installation hole 34. The side of the thrust pad near the bearing body of the three structures is wrapped with PEEK polymer Object layer 6, every set of thrust bearings has at least one second thrust tile and at least one third thrust tile, and each thrust tile is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com