Automatic bamboo pole inserting film laying machine of radix isatidis thermal insulation shed in medical industry

A heat preservation shed, isatis root technology, applied in plant protection, plant protection cover, botanical equipment and methods, etc., can solve the problems of increasing the planting cost of isatis root, increasing labor, and large sowing area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

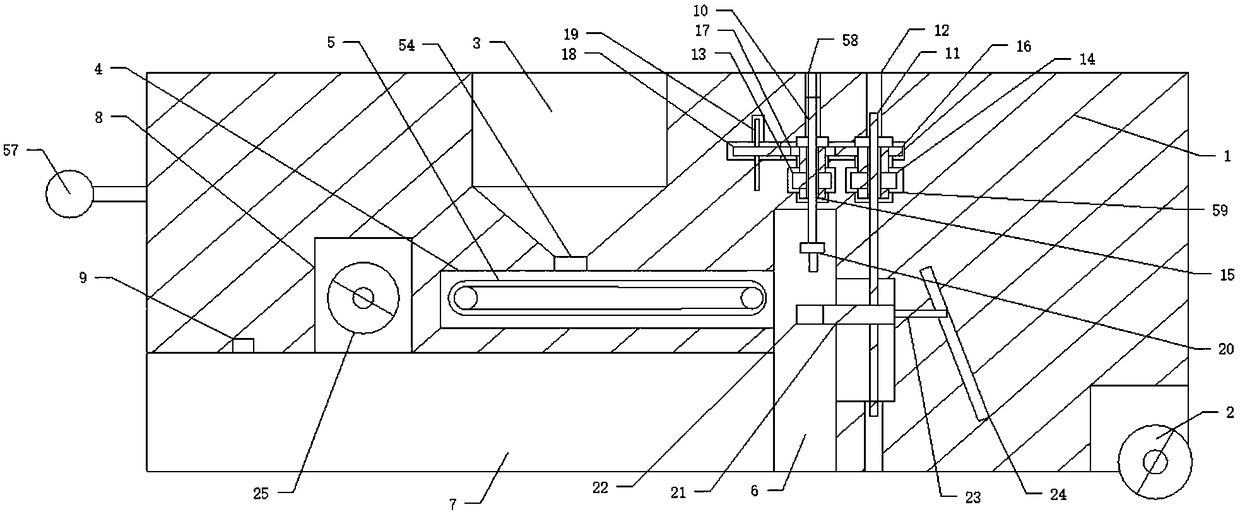

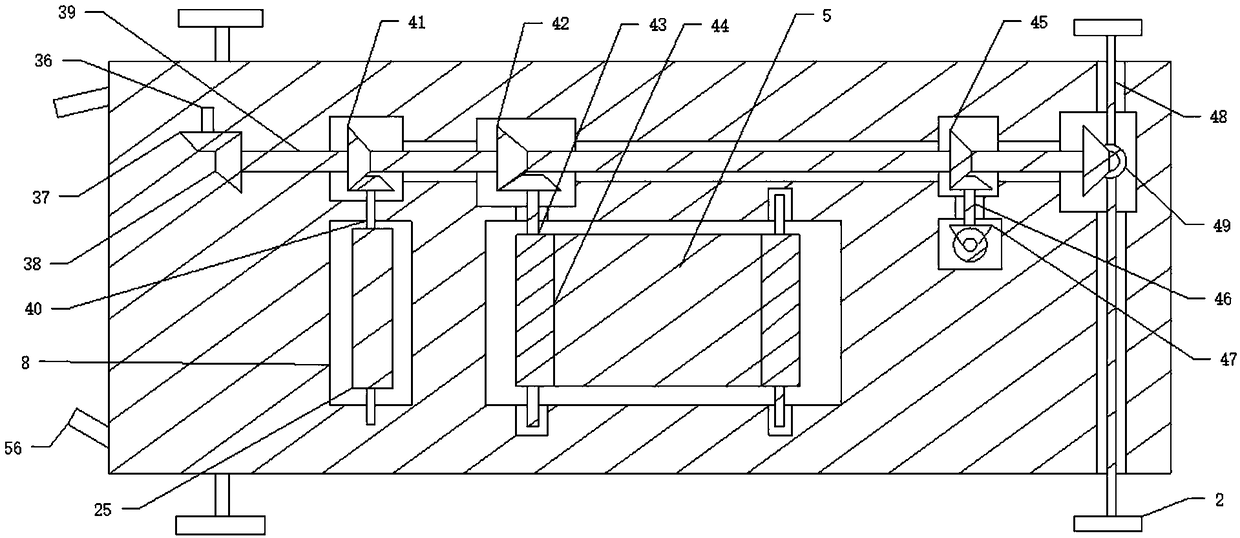

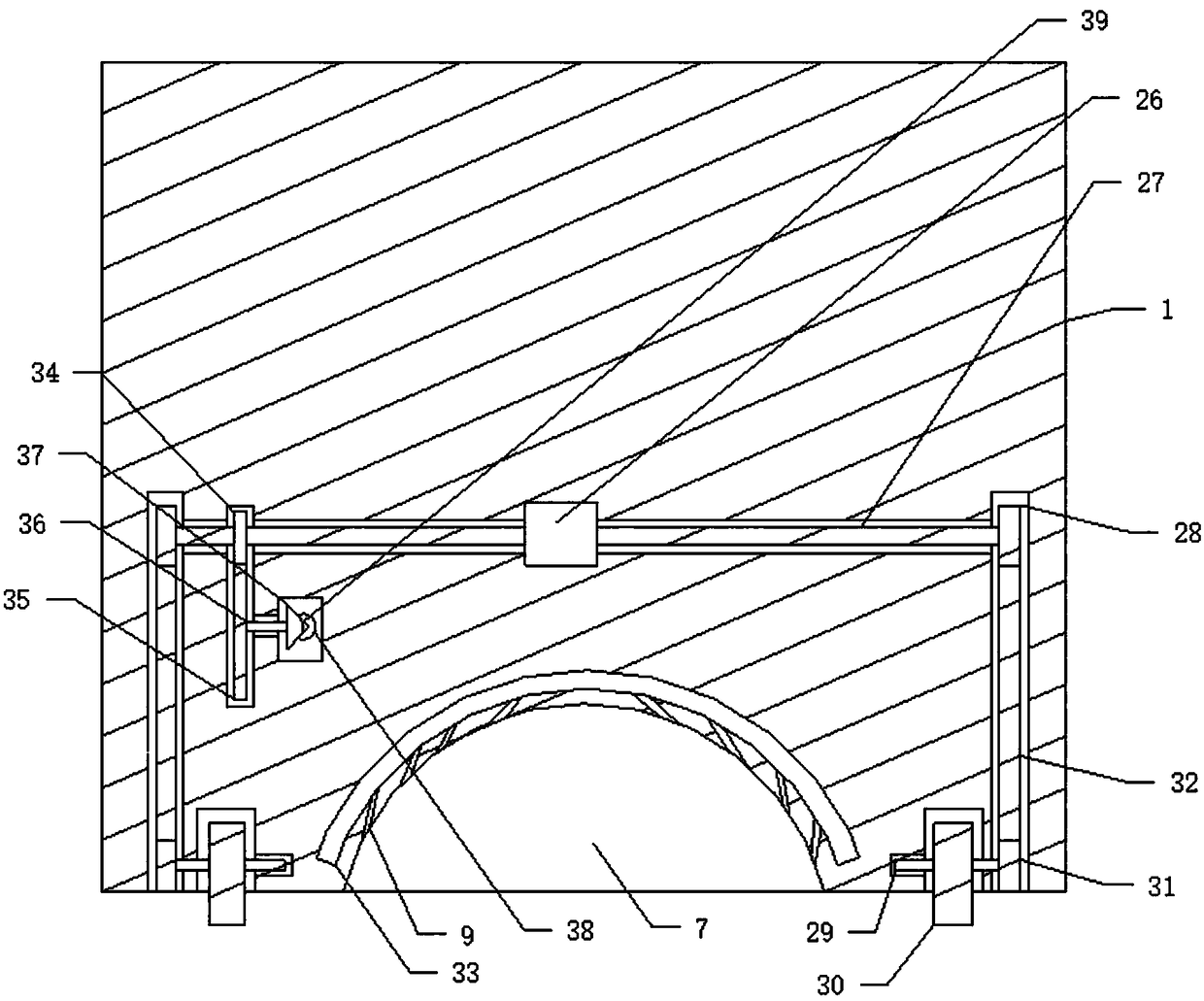

[0036] Such as Figure 1 to Figure 7 As shown, a bamboo pole automatic inserting and filming machine for isatis root insulation shed in the medical industry includes a body 1, a storage tank 3 is arranged on the body 1, and a storage tank 3 is also arranged in the body 1. 3 corresponds to the connected first conveying trough 4, a rotating conveying belt 5 is arranged in the first conveying trough 4, and a circle of second grooves corresponding to the storage trough 3 is arranged on the conveying belt 5 55.

[0037] A storage tank 3 is provided on the body 1, and the bamboo poles can be stored through the storage tank 3. A first delivery tank 4 is arranged in the body 1, and a first delivery tank 4 is arranged in the first delivery tank 4. There is a rotating conveyor belt 5, on which a second groove 55 in a concave shape is arranged, and the rotation of the conveyor belt 5 can further drive the sliding of the second groove 55 The number of the second grooves 55 can be set ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com