Dual-power vegetable processing grinding machine

A vegetable processing and dual-power technology, which is applied in the field of dual-power vegetable processing roller compactors, can solve the problems of inseparability, hidden dangers, wet safety in processing places, etc., and achieve a good effect of quantitative transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

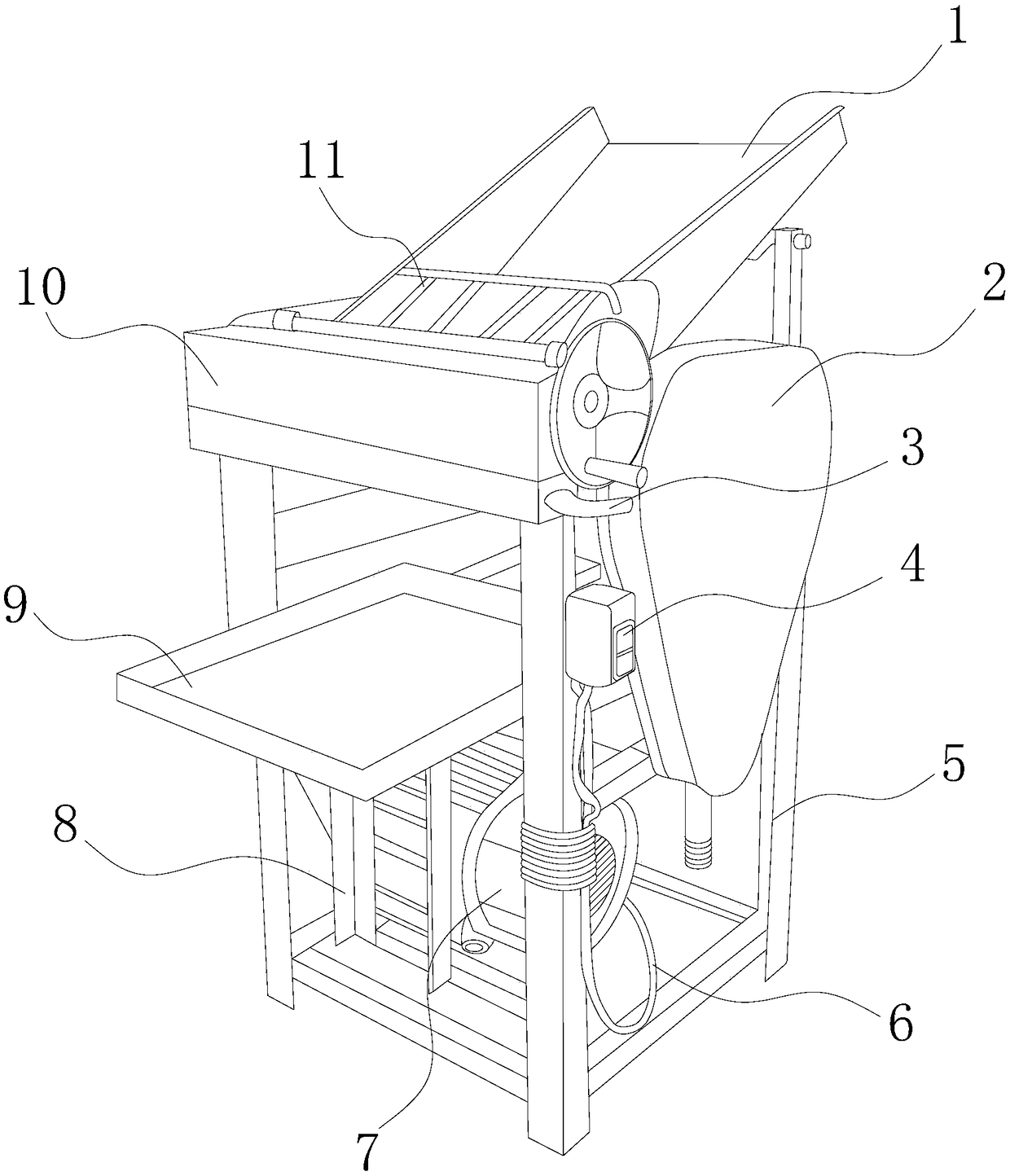

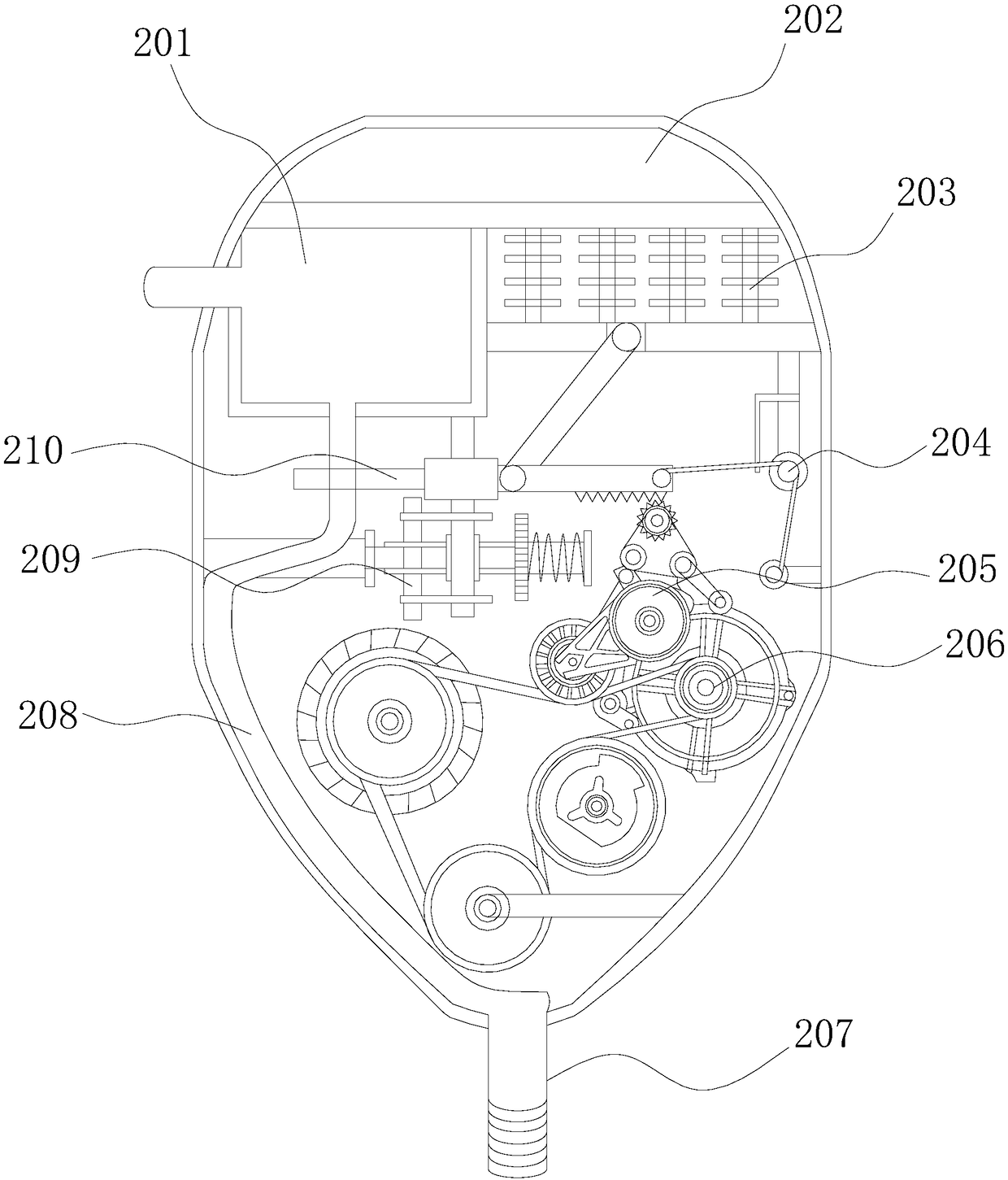

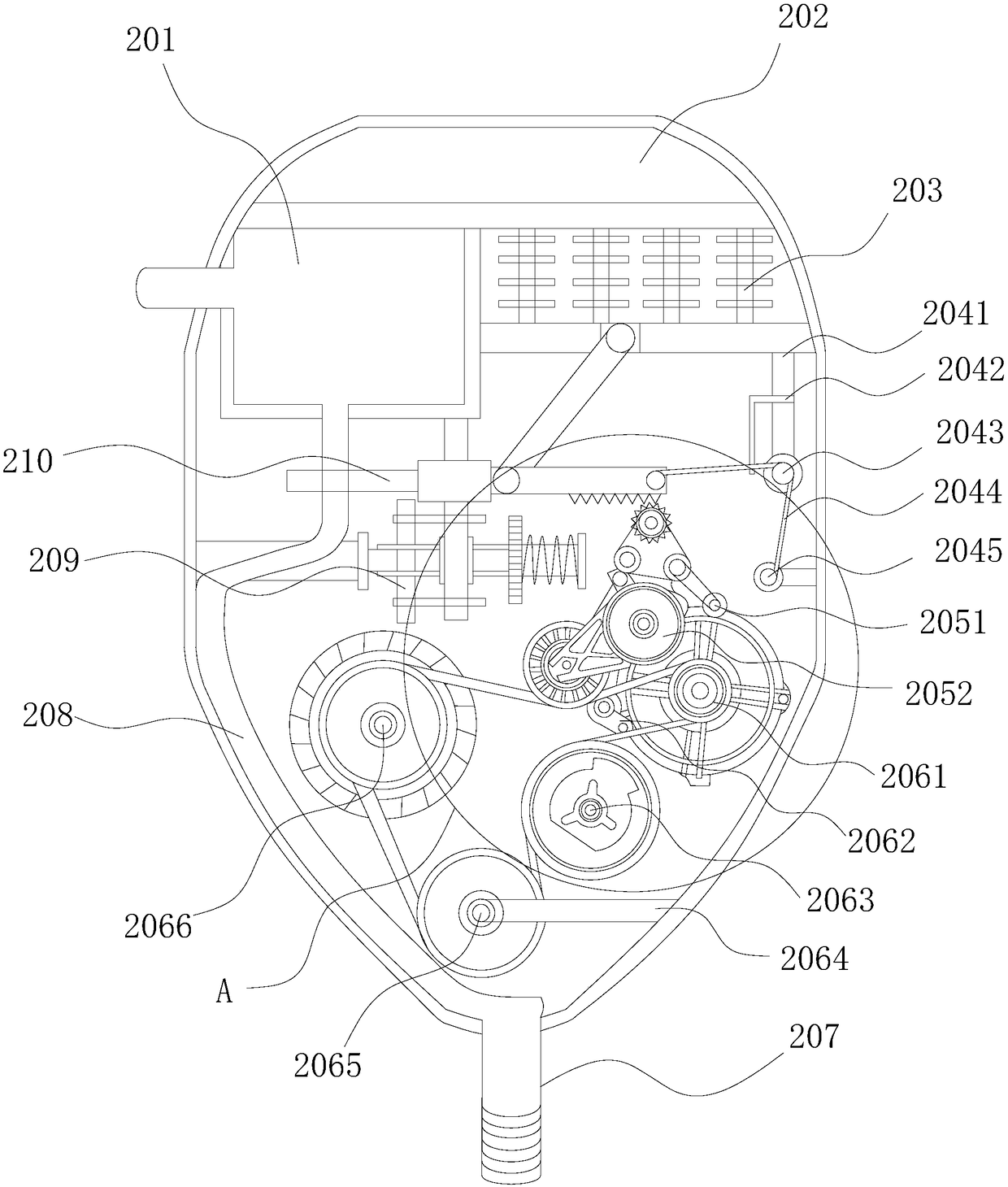

[0028] see Figure 1-Figure 5 , the present invention provides a dual-power vegetable processing rolling machine, the structure of which includes a feeding tray 1, a transmission control box 2, a draft tube 3, an electrical switch 4, a fixed frame 5, a connecting cable 6, a motor 7, a material receiving Plate fixing frame 8, material receiving plate 9, separation groove 10, protective cover 11, the inside of the fixed frame 5 is located at the bottom end of the material receiving plate 9 and a motor 7 is installed, and the bottom of the material receiving plate 9 passes through the material receiving plate The fixed frame 8 is vertically fixed in the fixed frame 5 and is located on the same plane as the motor 7, and the feeding tray 1 is fixed at 45° on the fixed frame 5, and its top end is installed on the fixed frame 5 and the bottom end is embedded in the inside of the separation groove 10 The left and right ends of the separation groove 10 are mechanically connected to the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap