Efficient definite proportion mixing production system and process of coating

A fixed-ratio mixing and production system technology, applied in rosin coatings, reflective/signal coatings, coatings, etc., can solve the problems of high production cost, easy to cause traffic accidents, low production efficiency, etc., to improve production stability, The effect of improving energy efficiency and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

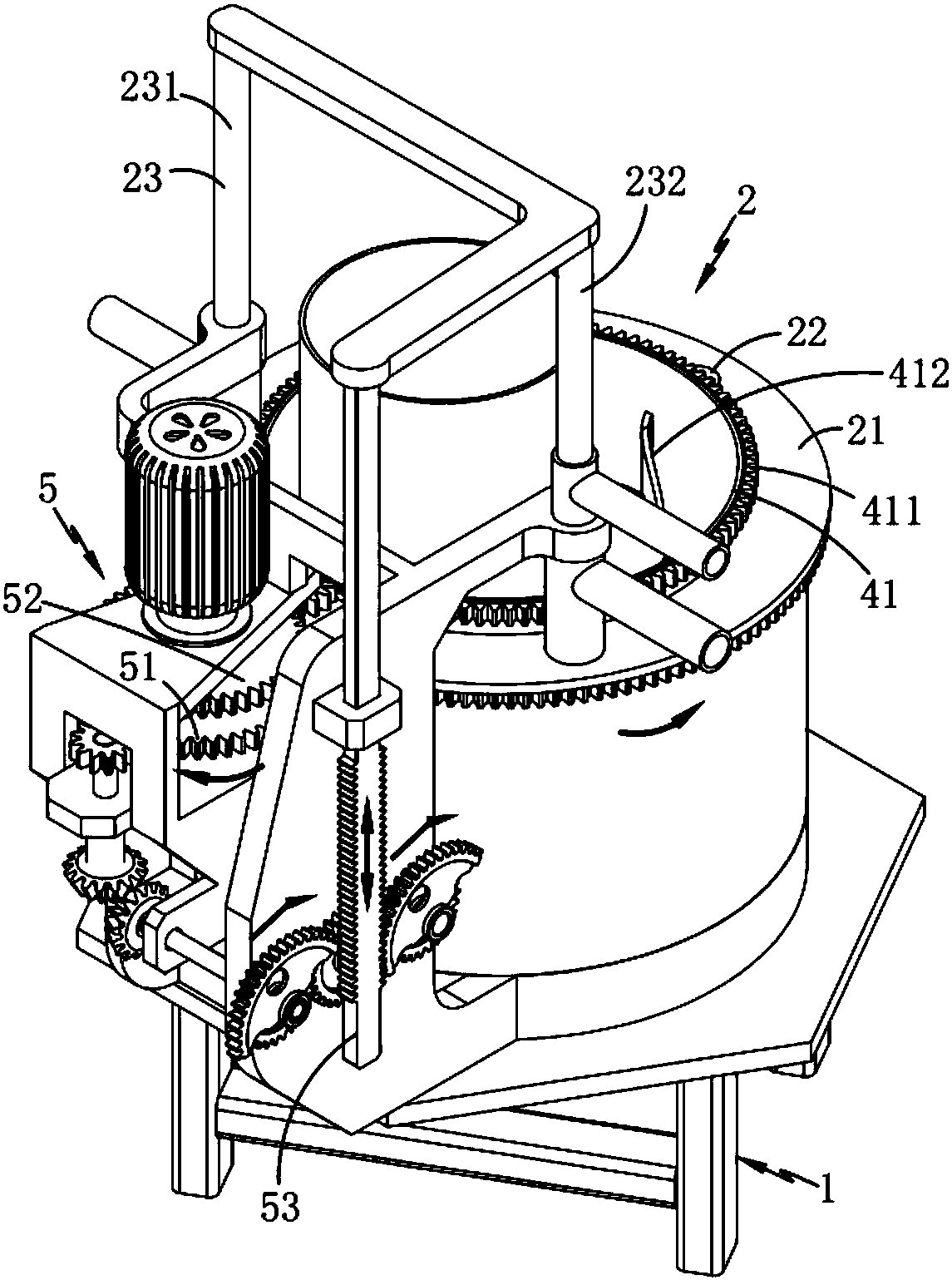

[0041] Such as figure 1 , 2 , 3 and 4, a high-efficiency fixed-ratio mixing production system for coatings, including frame 1, also includes:

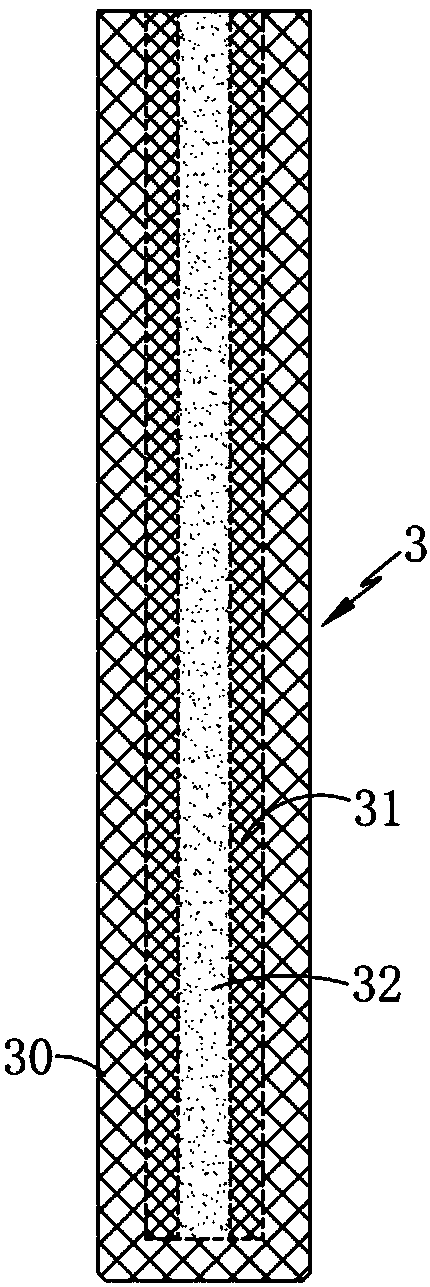

[0042] Forming mechanism 2, described forming mechanism 2 is installed on the described frame 1, and it comprises the transfer plate 21 that carries out material discontinuous delivery, opens a plurality of batching chambers 22 on this transfer board 21 and cooperates with this batching chamber 22 The forming component 23 of the compounding chamber 22 and the forming component 23 carry out fixed ratio batching to form a cylindrical structure synthetic material 3 of the main material 30, the modified material 31 and the auxiliary material 32 from the outside to the inside; in this embodiment, The batching chamber 22 is evenly distributed on the transfer plate 21 from top to bottom, and its number is three;

[0043]The filler proportioning mechanism 4 transmits the synthetic material 3 to the discharge port 11 provided on the frame 1 t...

Embodiment 2

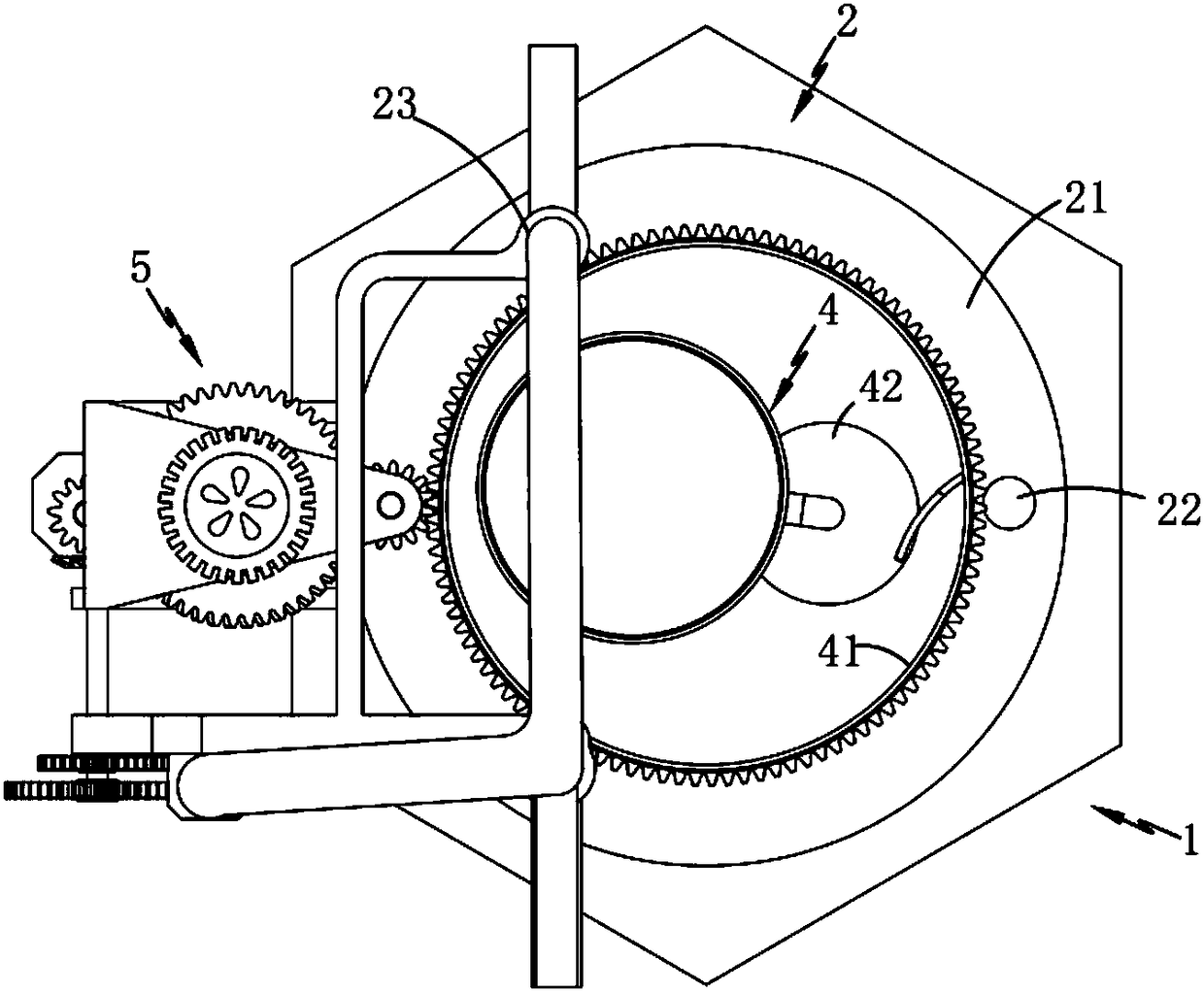

[0047] Such as figure 1 , 2 As shown in and 4, the components identical or corresponding to those in the first embodiment adopt the corresponding reference numerals of the first embodiment. For the sake of simplicity, only the differences from the first embodiment are described below. The difference between the second embodiment and the first embodiment is that the filler proportioning mechanism 4 is arranged at the center of the transfer plate 21, and the compression assembly 41 is a cylindrical structure and is coaxial with the transfer plate 21. Setting, the airbag 42 is eccentrically arranged inside the compression assembly 41, and the compression assembly 41 compresses and releases the airbag 42 once after the compression assembly 41 rotates to complete the output and introduction process of the filler 33 once.

[0048] It should be noted that the filler proportioning mechanism 4 is arranged at the center of the transfer plate 21, the compression assembly 41 is a cylindr...

Embodiment 3

[0050] Such as figure 1 As shown, the parts that are the same as or corresponding to those in Embodiment 2 are marked with the corresponding reference numerals in Embodiment 1. For the sake of simplicity, only the differences from Embodiment 2 will be described below. The difference between this third embodiment and the first embodiment is that the power assembly 5 also includes a third transmission assembly 53 that drives the molding assembly 23 to move up and down, and the third transmission assembly 53 and the first transmission assembly 51 is connected and the first transmission assembly 51 drives the third transmission assembly 53 to move after the material transfer of the transfer plate 21; in this embodiment, the first transmission assembly 51 is set as a half gear. Among them, firstly, the first transmission assembly 51 drives the transfer plate 21 to rotate for station conversion, the first transmission assembly 51 is separated from the transfer plate 21, and is conne...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap