Stainless steel plate calendaring device

A calendering device and stainless steel plate technology, applied in chemical instruments and methods, separation methods, precipitation separation, etc., can solve the problems of calendering oil removal, affecting product quality, and small pits on the surface of stainless steel plates, so as to keep clean and improve The effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

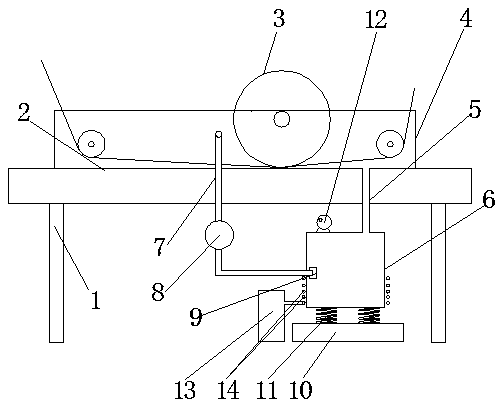

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

[0013] Such as figure 1 As shown, the stainless steel plate calendering device includes a frame 1, a calendering platform 2 is arranged on the frame, and a calendering roller 3 is installed on the calendering platform, and an oil tank 4 is arranged around the calendering platform, and the calendering roller is just inside the oil tank. It is characterized in that: the bottom of the oil tank is connected with a sedimentation tank 6 by a pipeline 5, the sedimentation tank is connected with the oil tank by an upward pipe 7, a pump 8 is installed in the middle of the upward pipe, and a filter screen 9 is installed in the sedimentation tank.

[0014] In this way, the calendering oil used is the calendering oil that has been precipitated and filtered to remove impurities and dust, and keep the calendering oil clean, which is beneficial to the quality of the packaging product...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com