Precise clamping rotary hydraulic manipulator

A manipulator and clamping technology, which is applied in the field of manipulators, can solve the problems of affecting the gripping stability of manipulators, low flexibility of movement adjustment, and affecting gripping accuracy, etc., and achieves simple structure, strong practicability, and improved precision. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

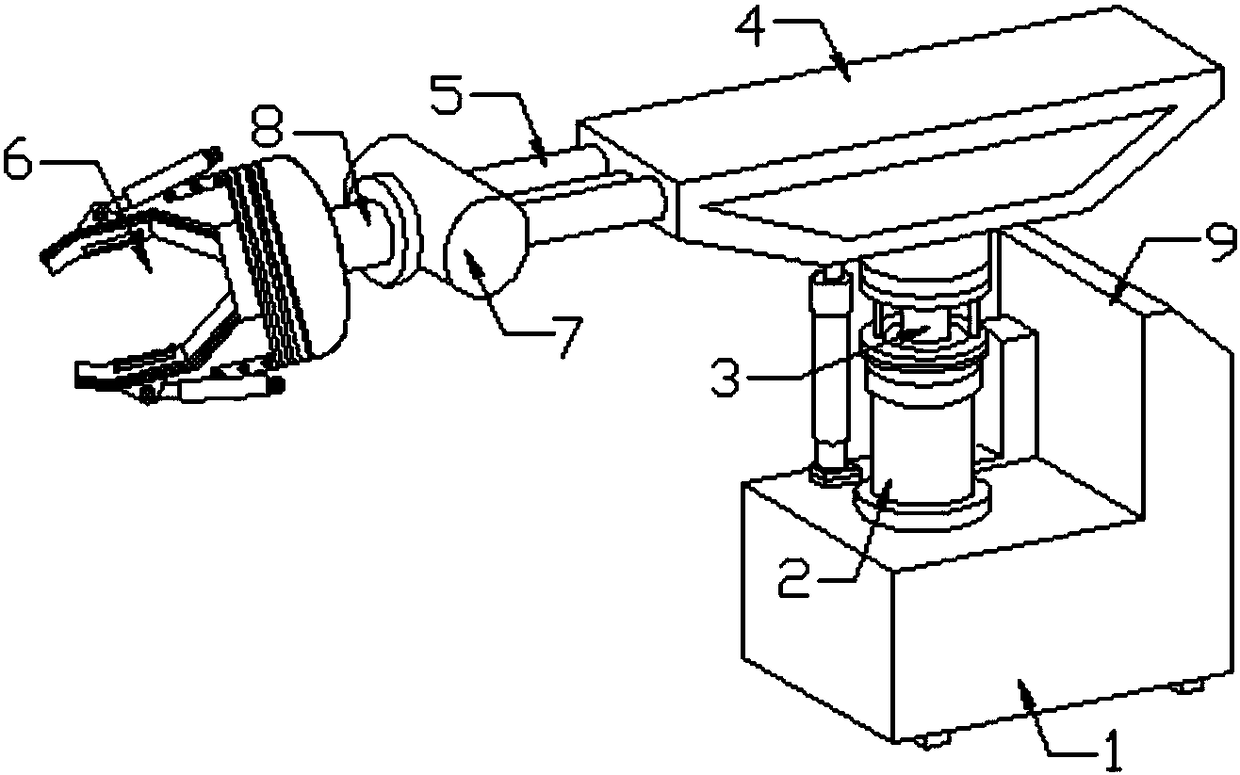

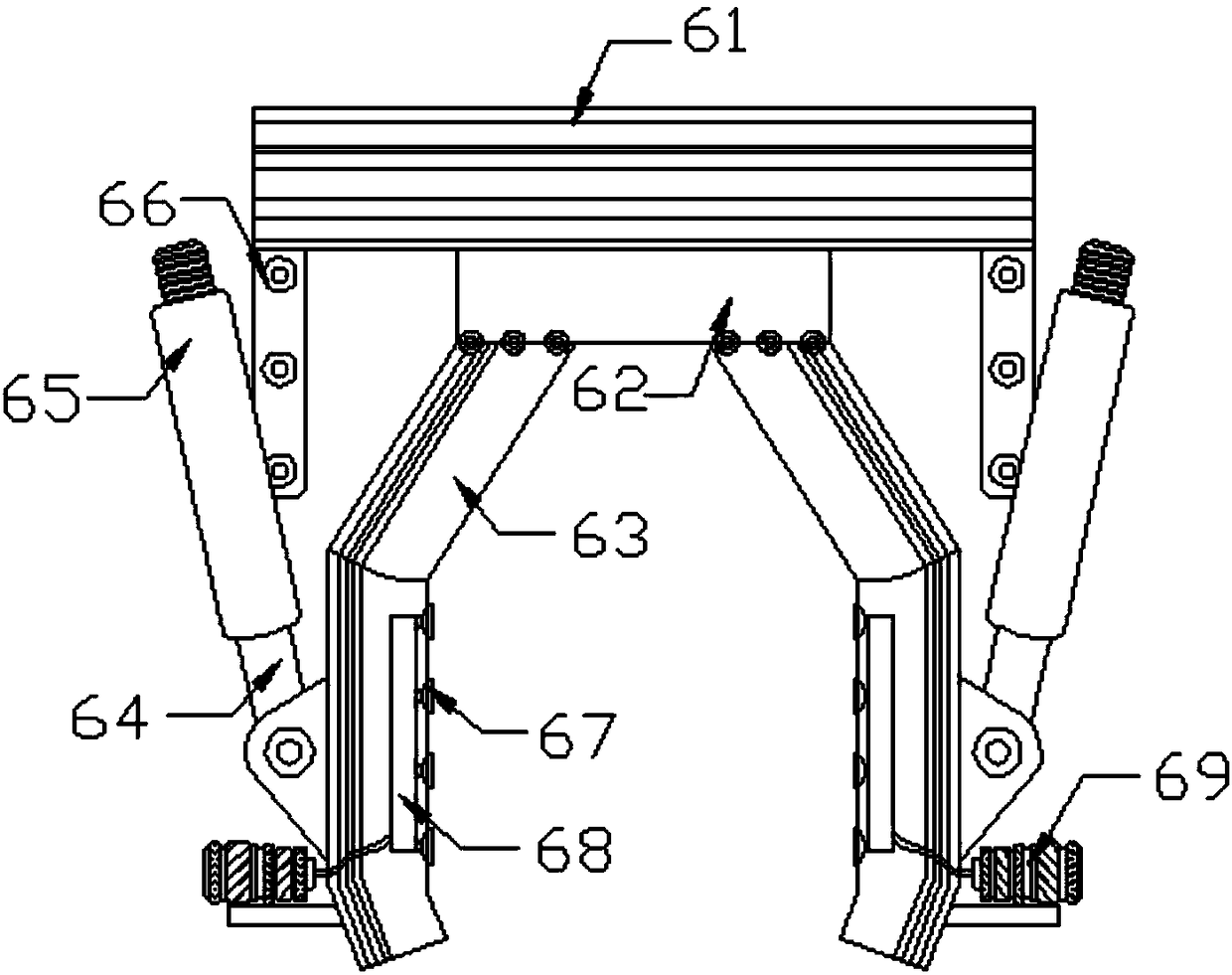

[0016] Example: such as Figure 1-2 As shown, a precise clamping type rotary hydraulic manipulator of the present invention includes a load-bearing base 1, a mechanical arm 4 and a clamping manipulator 6, and a rotary table 2 is installed on the top of the load-bearing base 1, and the rotary table 2 includes a rotary motor and the rotating disk connected with the rotating motor, the top of the rotating table 2 is equipped with a first hydraulic cylinder 3, the top of the first hydraulic cylinder 3 is equipped with a mechanical arm 4, and one end of the mechanical arm 4 is fixedly installed with The second hydraulic cylinder 5, the output end of the second hydraulic cylinder 5 is equipped with a drive motor 7, the output end of the drive motor 7 is connected to the connecting shaft 8 through a coupling, and one end of the connecting shaft 8 is fixedly installed There is a clamping manipulator 6, and the clamping manipulator 6 includes a mounting seat 61 connected to the connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com