Device for removing iron-containing impurities from plastic raw materials

A technology for raw materials and impurities is applied in the field of devices for cleaning iron-containing impurities in plastic raw materials, which can solve the problems of low iron removal rate and inconvenient treatment of iron impurities, and achieve the effect of improving iron removal rate and continuous cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

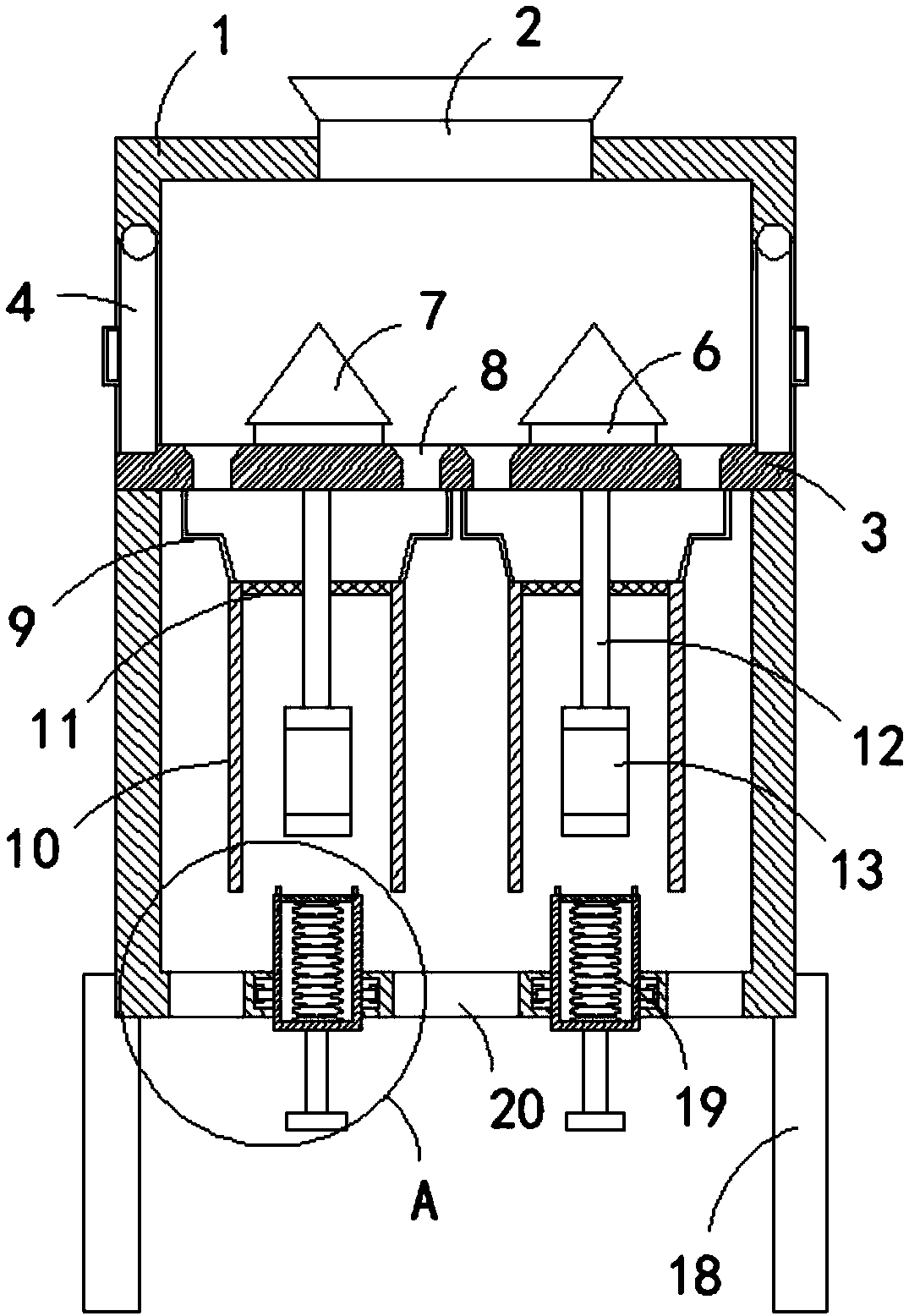

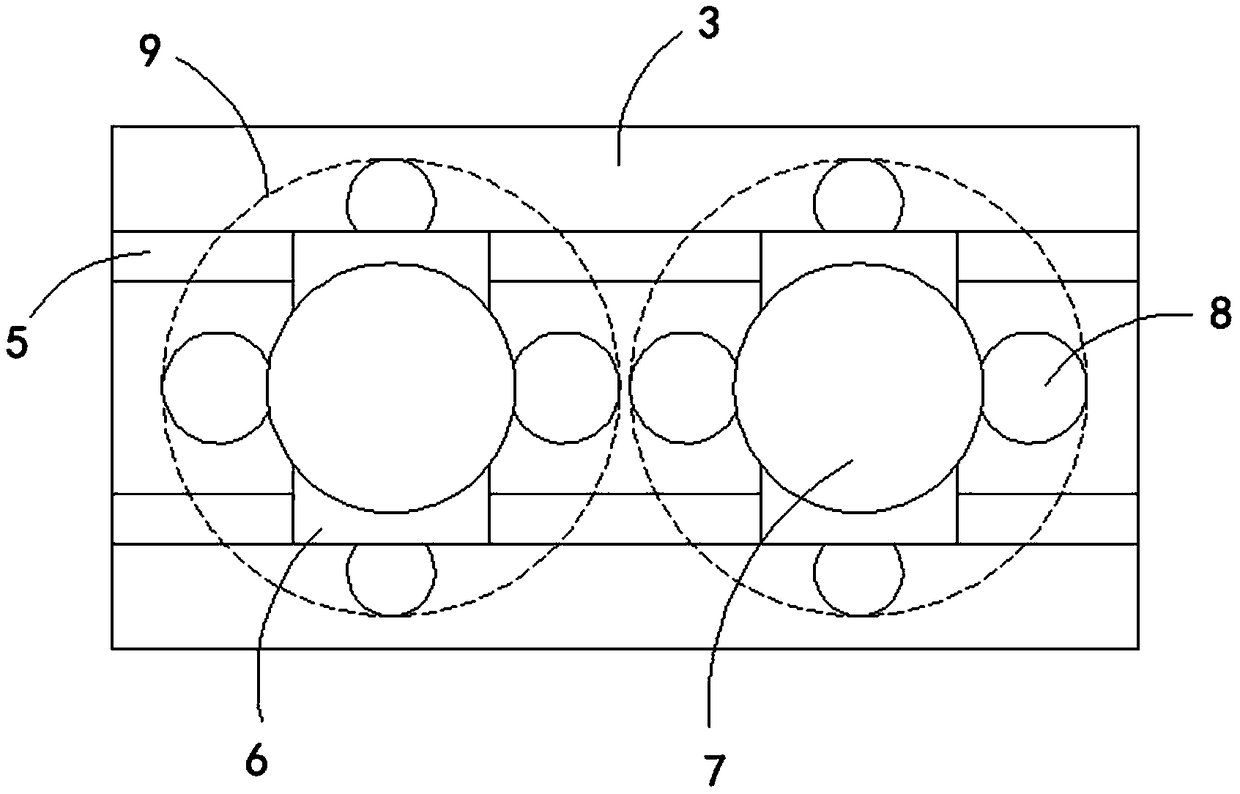

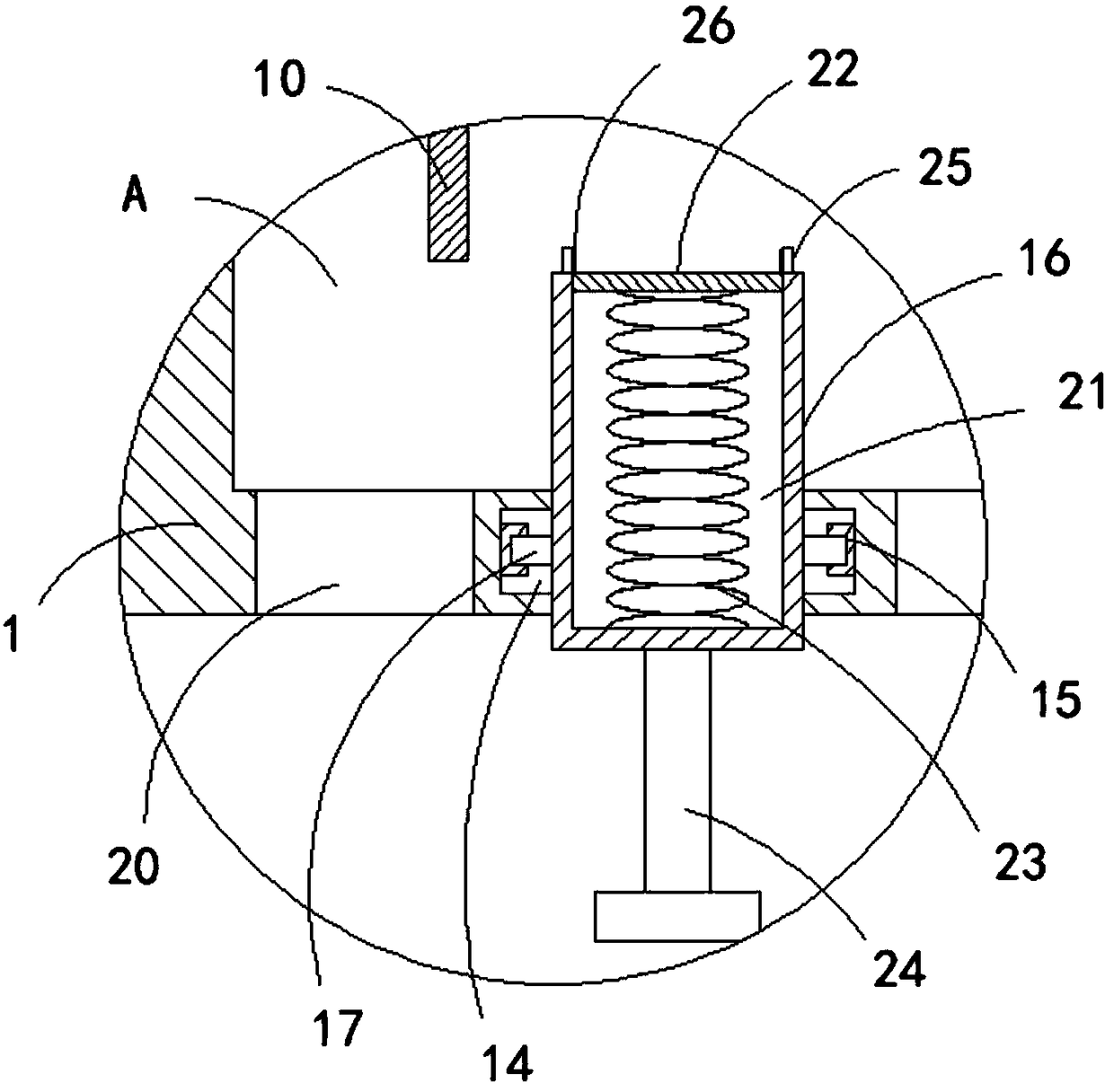

[0018] refer to Figure 1-3 , a device for cleaning iron-containing impurities in plastic raw materials, comprising a housing 1, wherein a plurality of vertical support columns 18 are fixedly connected to the bottom wall of the housing 1, and the upper end of the housing 1 is provided with a feeding mouth 2, a horizontal support plate 3 is fixedly connected between the left and right inner walls of the housing 1, and a revolving door 4 is rotatably connected to the left and right side walls of the housing 1, and the revolving door 4 is correspondingly installed on the upper side of the supporting plate 3, The upper end of the support plate 3 is provided with two mutu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com