A method for catalyzing monopersulfate to generate sulfate radicals to degrade organic matter

A technology for refractory organics, persulfate, applied in chemical instruments and methods, molecular sieve catalysts, chemical/physical processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A method for catalyzing monopersulfate to produce sulfate radicals to degrade organic matter, comprising the following steps:

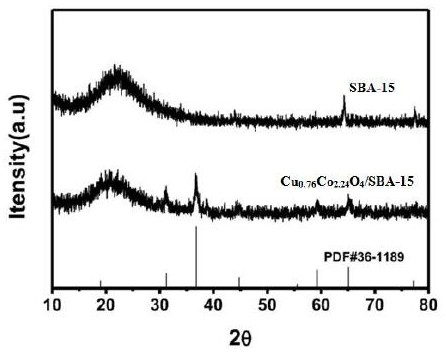

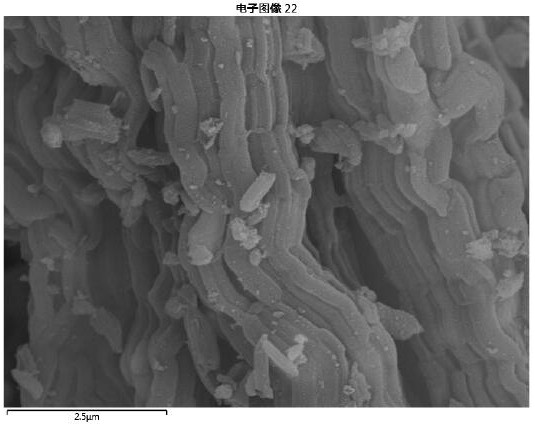

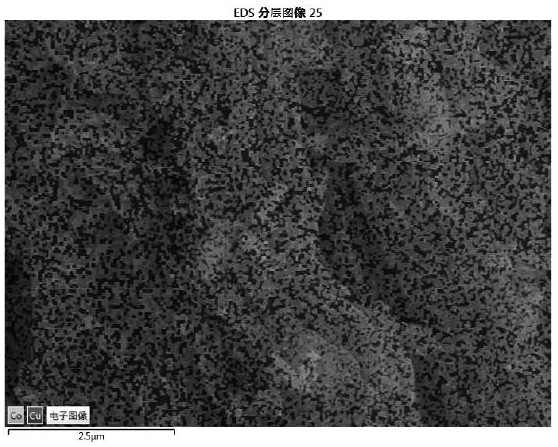

[0042] A. Preparation of Cu 0.76 co 2.24 o 4 / SBA-15 catalyst

[0043] a. Accurately weigh 0.4938gCo(NO 3 ) 2 ▪6H 2 O and 0.1543gCu(NO 3 ) 2 ▪3H 2 O in a 100mL beaker, ultrasonically dissolved with 40mL triple distilled water, and then 1.0000g SBA-15 molecular sieve was added to it for ultrasonic dissolution for 30min;

[0044] b. Put the mixed solution after ultrasonic dissolution in step a into a magnetic stirrer, stir and evaporate until there is no obvious water in the mixed solution, wherein the stirring temperature of the magnetic stirrer is 60°C;

[0045] c. drying the magnetically stirred mixture in step b at 100° C. for 12 hours to obtain a molecular sieve mixture;

[0046] d. Place the molecular sieve mixture prepared in step c into a tube furnace for roasting, wherein the heating rate of the tube furnace is 2° / min, and roa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com