Sectional hoisting method of self-supporting steel chimney upside-down mounting assembling method

A segmented hoisting, self-supporting technology, applied in building types, buildings, towers, etc., can solve the problems of self-supporting steel chimneys, such as large limitations, long mechanical occupation time, and reduced stability, and achieves fast assembly speed and occupation. The effect of less space and shorter occupation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] A self-supporting steel chimney inverted assembly method for segmental hoisting, comprising the following steps:

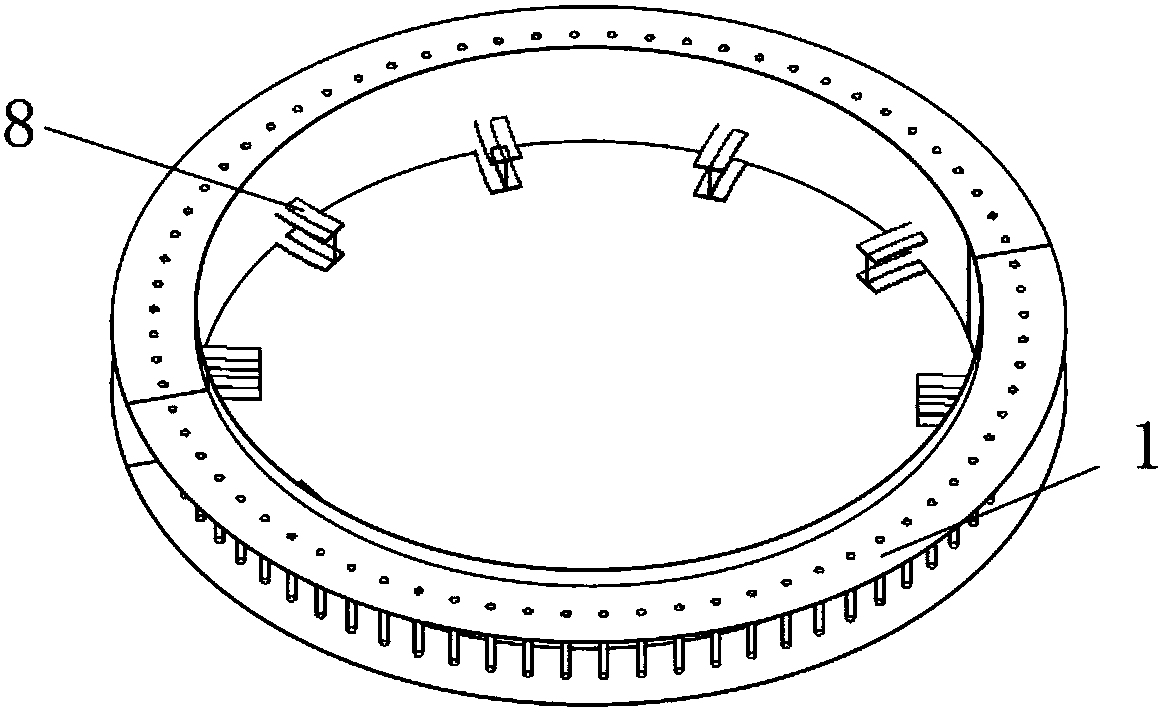

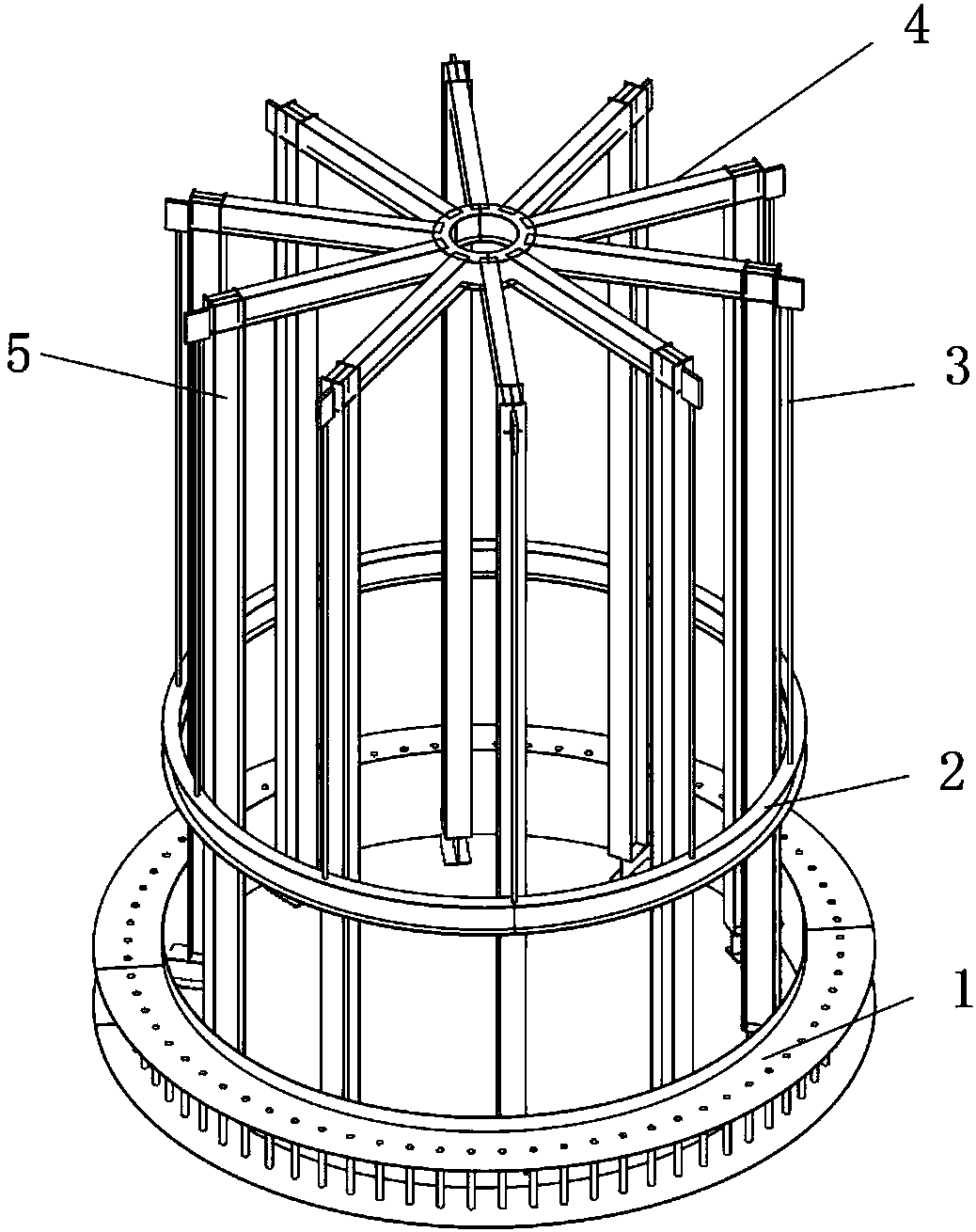

[0027] 1. On a circular foundation (such as Figure 8 ) to install the chimney base 1 at the design position (such as figure 1 shown), and a plurality of steel corbels 8 are evenly welded along the circumference of the base, and a steel column 5 is welded on each steel corbel, and a plurality of steel columns form a circular array of steel columns;

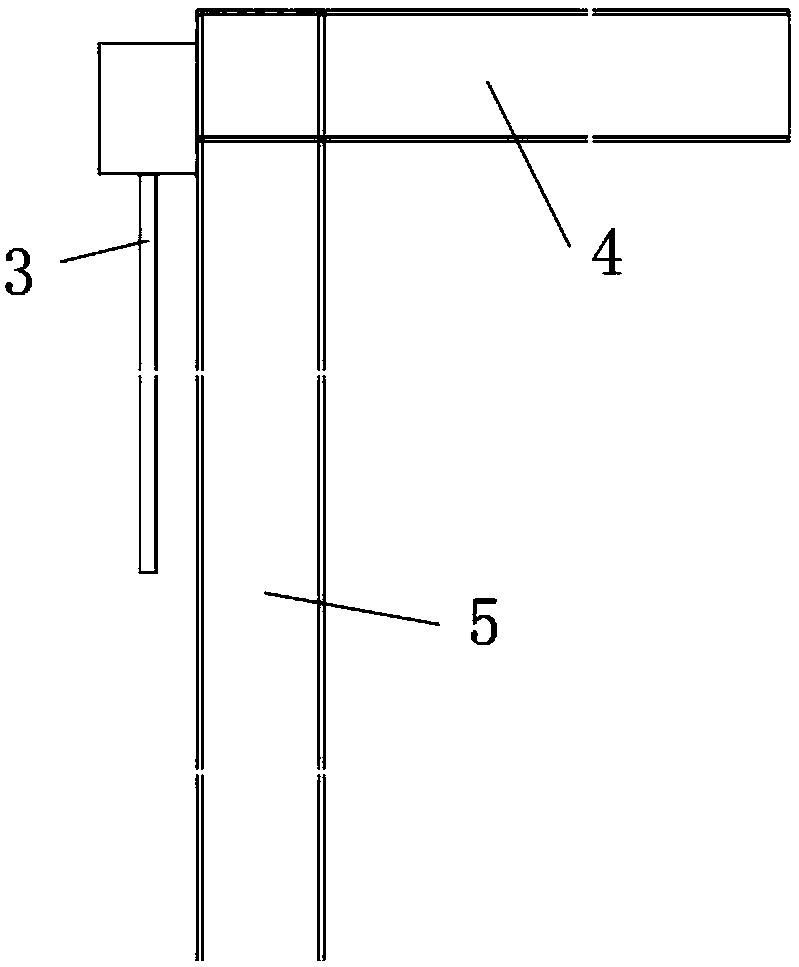

[0028] 2. After installing all the steel columns 5, weld the inter-column support frame 4 firmly to each steel column, weld the lifting lugs on the outside of the top of each steel column 5, and firmly fix the chain block 3 on the lifting lugs; ( Such as figure 2 shown)

[0029] 3. Wrap the segmented ring beam 2 around the outside of the ring array of steel columns and weld it into a whole. Weld the lifting lugs on the upper surface of the ring beam 2 and the corresponding position of the chain hoist 3. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com