Surrounding Rock Permeability Multi-stage Water Injection Observer

A technique of permeability and observation instrument, which is applied in wellbore/well components, sealing/isolation, earthwork drilling and production, etc. It can solve problems such as device plugging and observation process, equipment not working normally, and gas supply pipelines that are easy to break , to achieve the effects of sensitive and balanced pressure regulation, avoiding damage, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

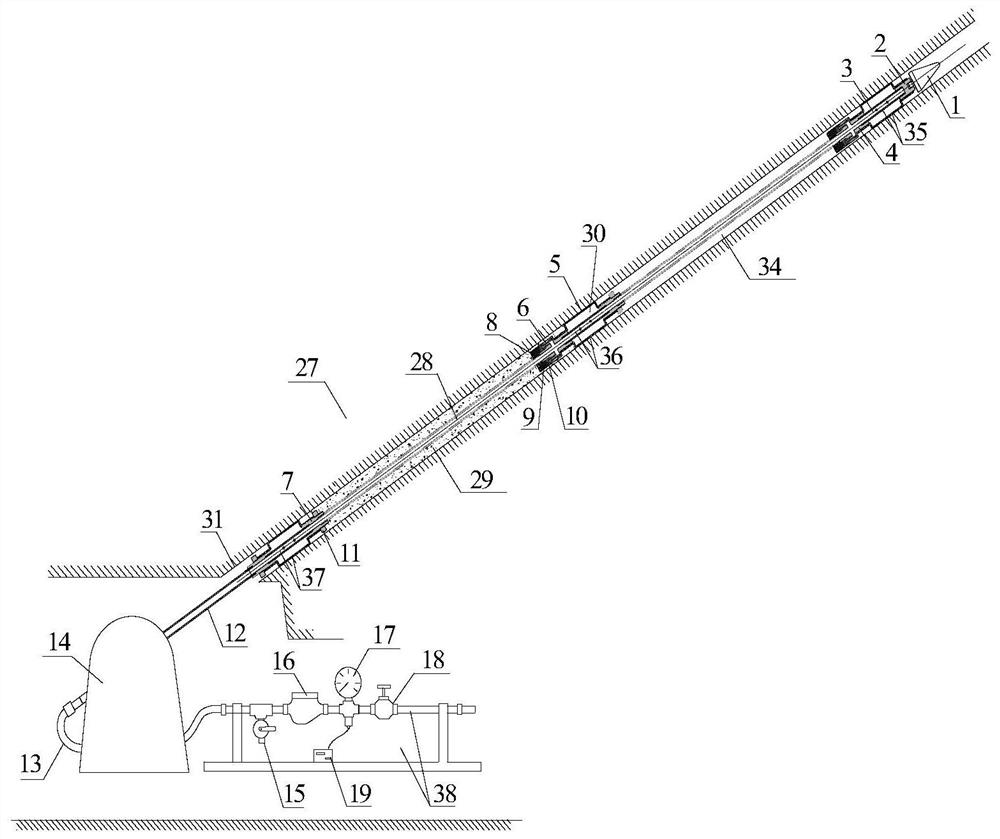

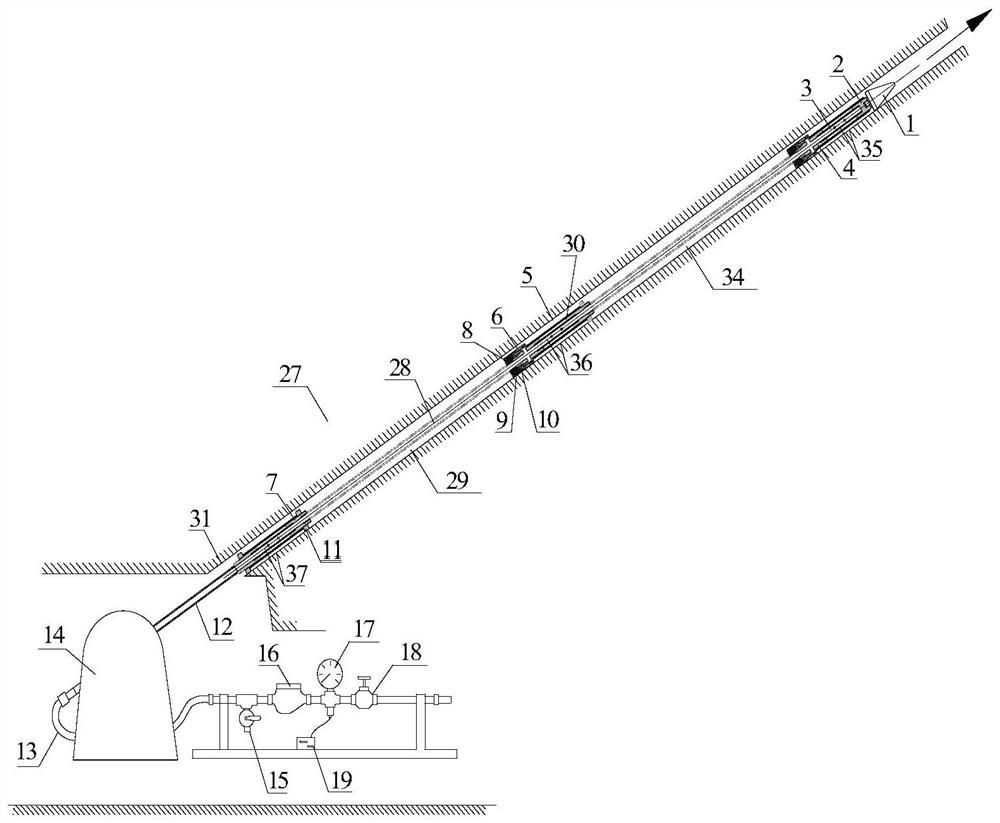

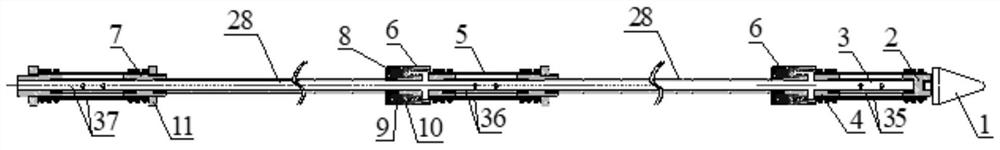

[0052] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

[0053] A multi-stage water injection observer for surrounding rock permeability, including a test probe, a control console 38, a drilling rig 14 and a drill pipe 12;

[0054] Described test probe comprises occluder, converter 6 and connecting pipe 28, and occluder comprises front part occluder 35, middle part occluder 36, tail end occluder 37; The joints at both ends of the leaking pipe and the rubber bag 5, the rubber bag 5 wraps around the periphery of the leaking pipe 3, forms a sealing cavity 30 with the leaking pipe 3, and the external water source injects the sealing cavity 30 to swell the rubber bag 5, and Borehole 31 forms water injection cavity;

[0055] The drilling rig 14 is connected with the test probe through the drill rod 12 to extend and advance the test probe to a designated area. The dril...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com