Installation structure and construction method of pipeline rotary compensator on large area of water

A technology of rotating compensator and installation structure, which is applied in the direction of pipeline laying and maintenance, transportation and packaging, pipe/pipe joint/pipe fitting, etc., which can solve problems such as limited working range, achieve high safety, save construction cost, and operate strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

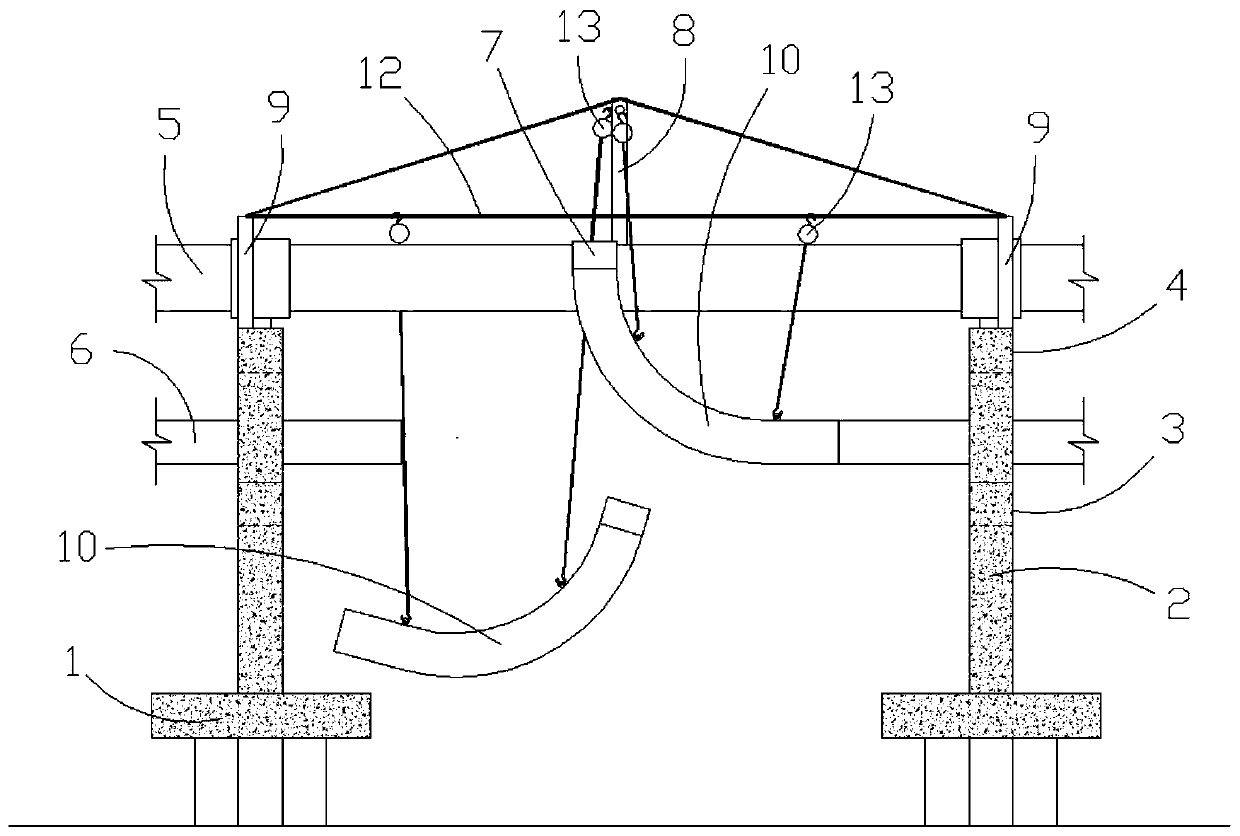

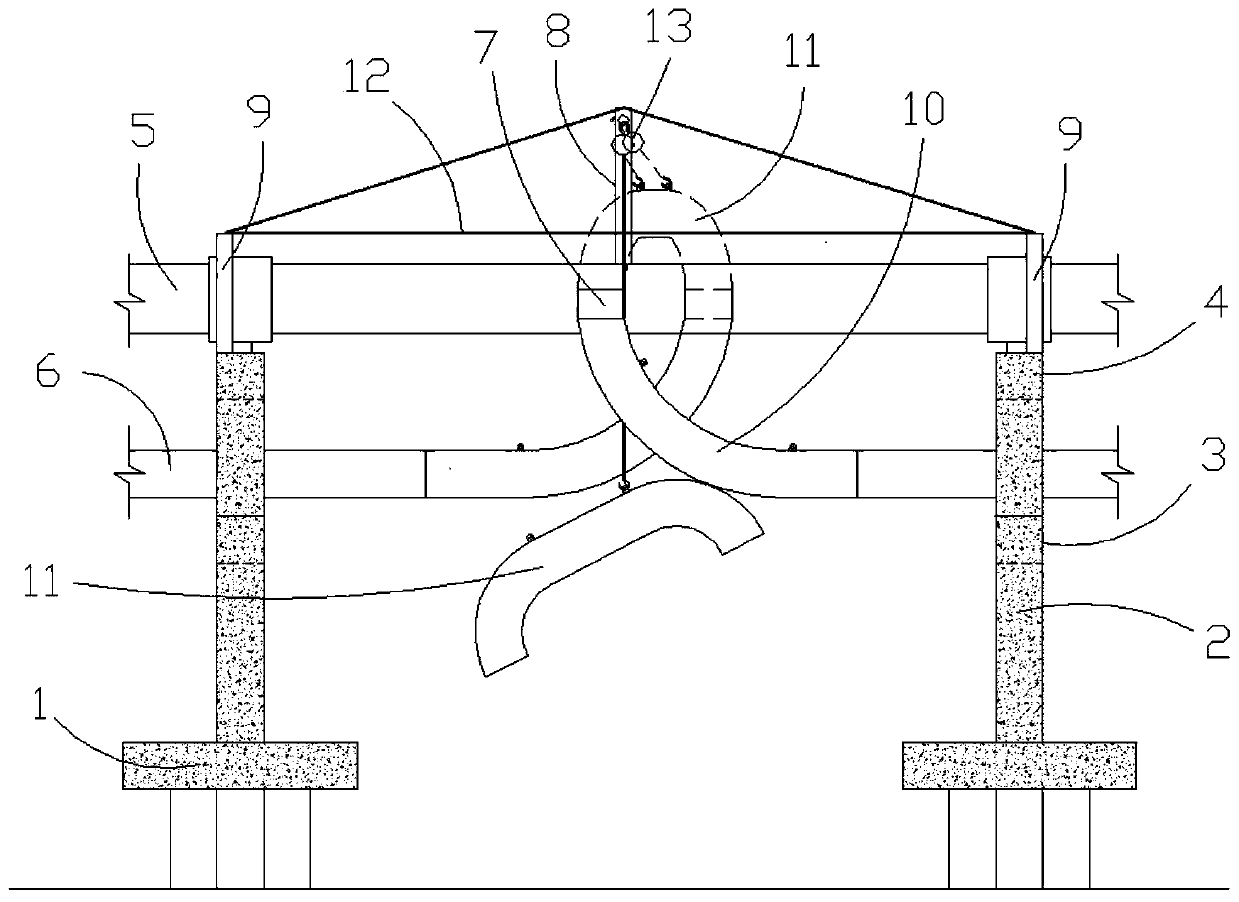

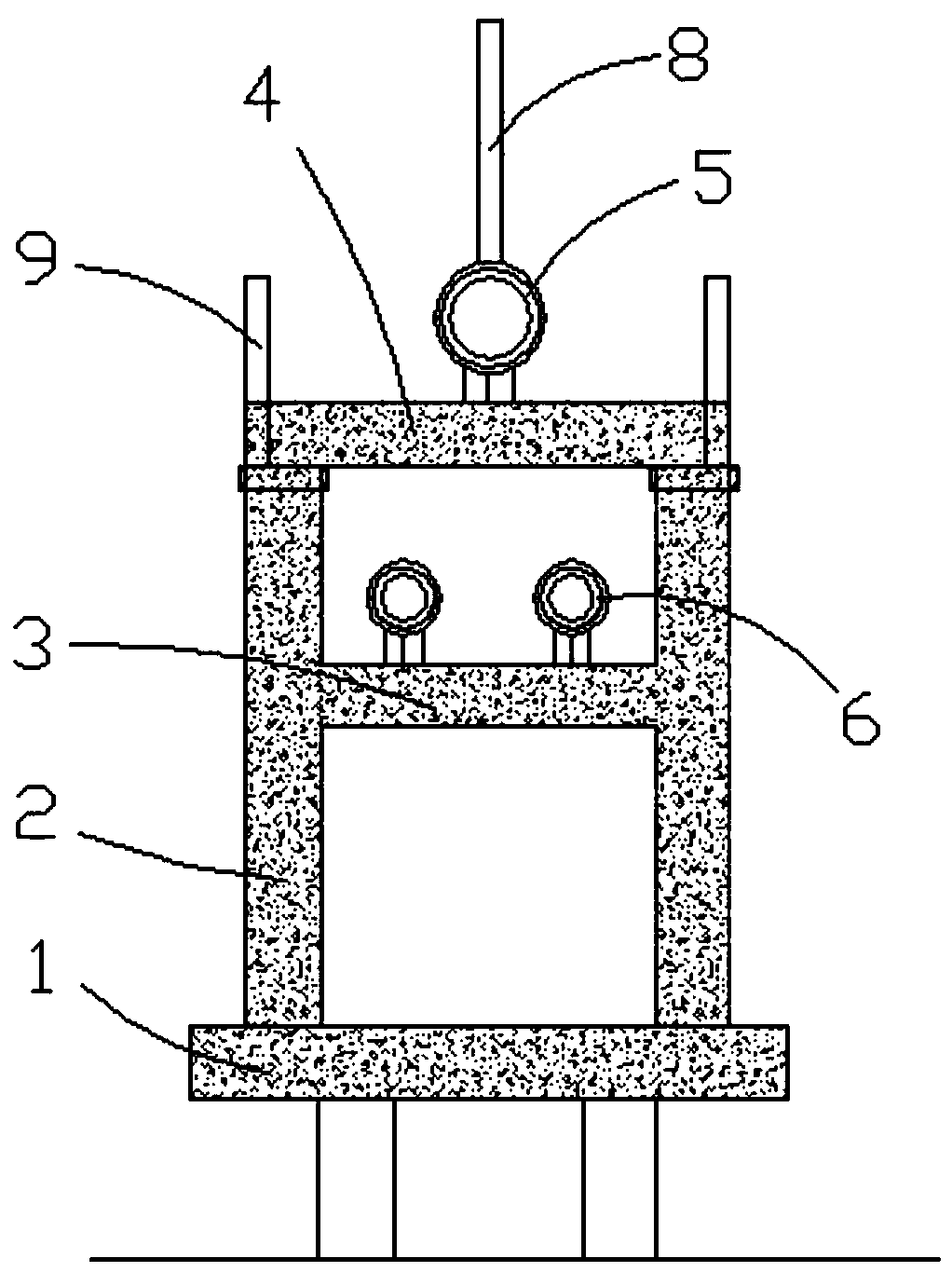

[0024] The present invention will be described in further detail below in conjunction with accompanying drawing, so that those skilled in the art can understand more clearly, as figure 1 and figure 2 As shown, the installation structure of the pipeline rotary compensator on the large-area water area of the present invention includes: two pile caps 1 on the water; concrete supports are respectively fixed on the two pile caps 1, and the concrete supports include a pair of columns 2, The connecting beam 3 and the top beam 4, the lower ends of the two columns 2 are fixed on the pile cap 1, the two ends of the top beam 13 are fixed on the upper ends of the two columns 11, the connecting beam 3 below the top beam 4 The two ends are fixed on the column 2; the main heating pipe 5 is fixed on the top beam 4 of the concrete support through the pipe support, and there are two pairs of auxiliary heating pipes 6 below the main heating pipe 5. The pipe 6 is fixed on the connecting beam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com