Numerical control plasma underwater cutting device

A technology of a plasma cutting machine and a cutting device, which is applied to plasma welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of unreusable water, slow rise and fall of the water level in the pool, etc., so as to improve the cutting work efficiency and reduce the production cost. , the effect of reducing noise and dust pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

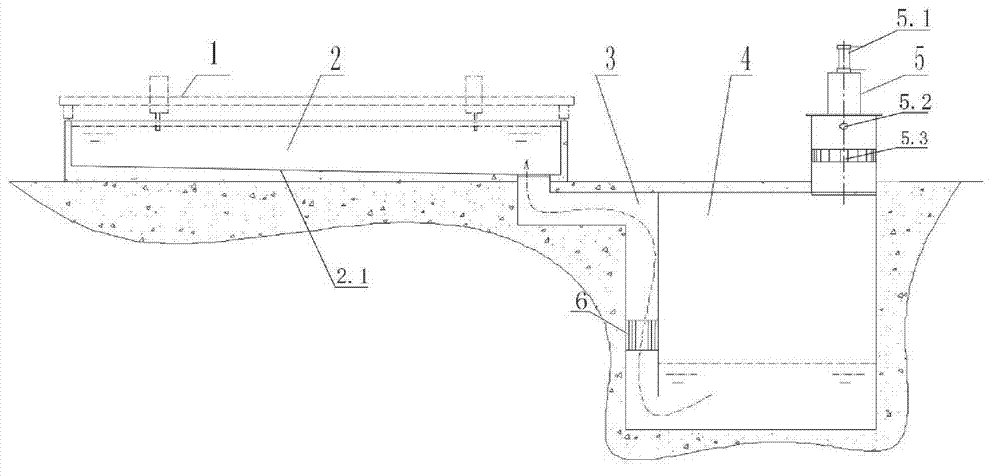

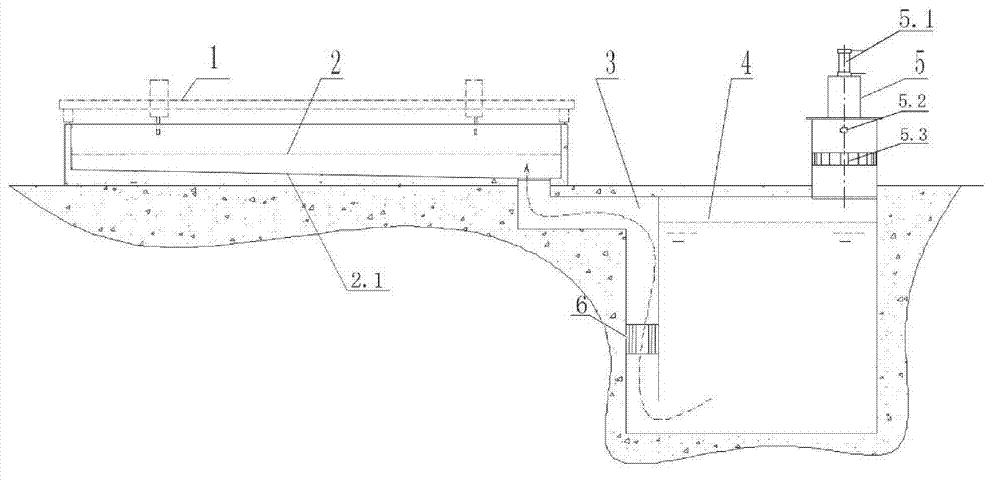

[0026] Such as Figure 1-2 As shown, the CNC plasma underwater cutting device includes a CNC plasma cutting machine 1 and a pool 2, the CNC plasma cutting machine 1 is arranged on the top of the pool 2, and the pool 2 is connected to the water tank 4 through a pipeline 3, wherein the pipeline 3 is also A filtering device 6 is provided, and the water tank 4 is arranged under the ground next to the pool 2. The volume of the water tank 4 is greater than that of the pool 2, and its top height is lower than the height of the bottom surface of the pool 2. The bottom of the pool 2 is a slope 2.1, and the slope Inclined towards the nozzle of the pipeline 3, the angle formed by the slope 2.1 and the horizontal plane is 3 degrees. The water tank 4 is also connected with a control pipeline 5, and the control pipeline 5 includes an air compressor, a surge tank 5.3, an intake valve and an exhaust valve, the intake valve is an electromagnetic valve 5.1, and the exhaust valve is an air contr...

Embodiment 2

[0029] The difference from Embodiment 1 is that the angle formed by the slope 2.1 and the horizontal plane is 8 degrees, and the other working principles are the same.

Embodiment 3

[0031] The difference from Embodiment 1 is that the included angle between the slope 2.1 and the horizontal plane is 5 degrees, and the other working principles are the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com