Internal rotation locking vacuum-pumping tank for high-temperature vacuum sintering furnace

A high-temperature vacuum and vacuuming technology, used in furnaces, muffle furnaces, cooking furnaces, etc., can solve the problems of unsteady vacuum degree, pressure relief and gas leakage, and achieve the effect of good sealing effect and sensitive and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to more clearly illustrate the technical solutions of the embodiments of the present invention, the following will briefly introduce the accompanying drawings that need to be used in the embodiments. Obviously, the accompanying drawings in the following description are some embodiments of the present invention. Ordinary technicians can also obtain other drawings based on these drawings on the premise of not paying creative work.

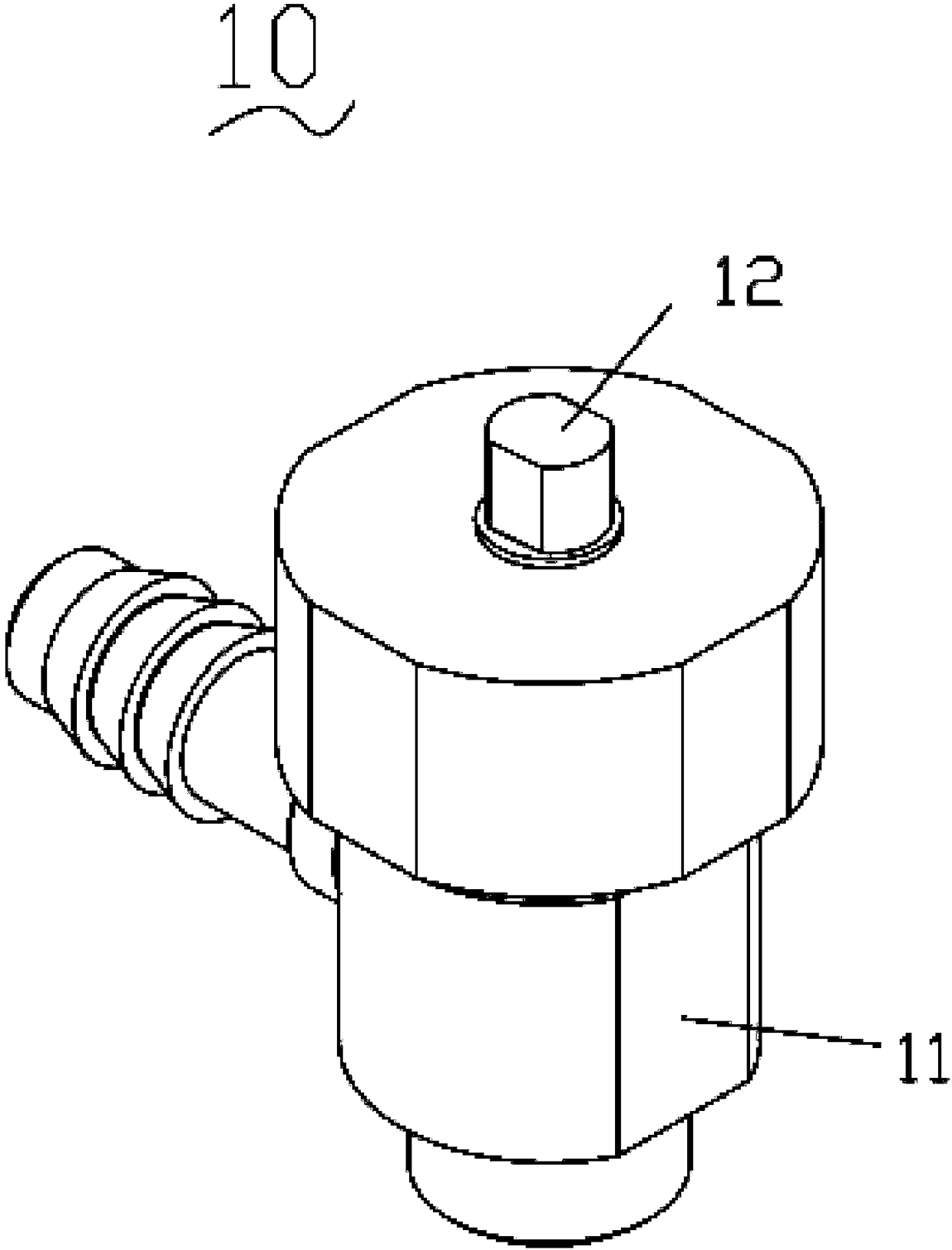

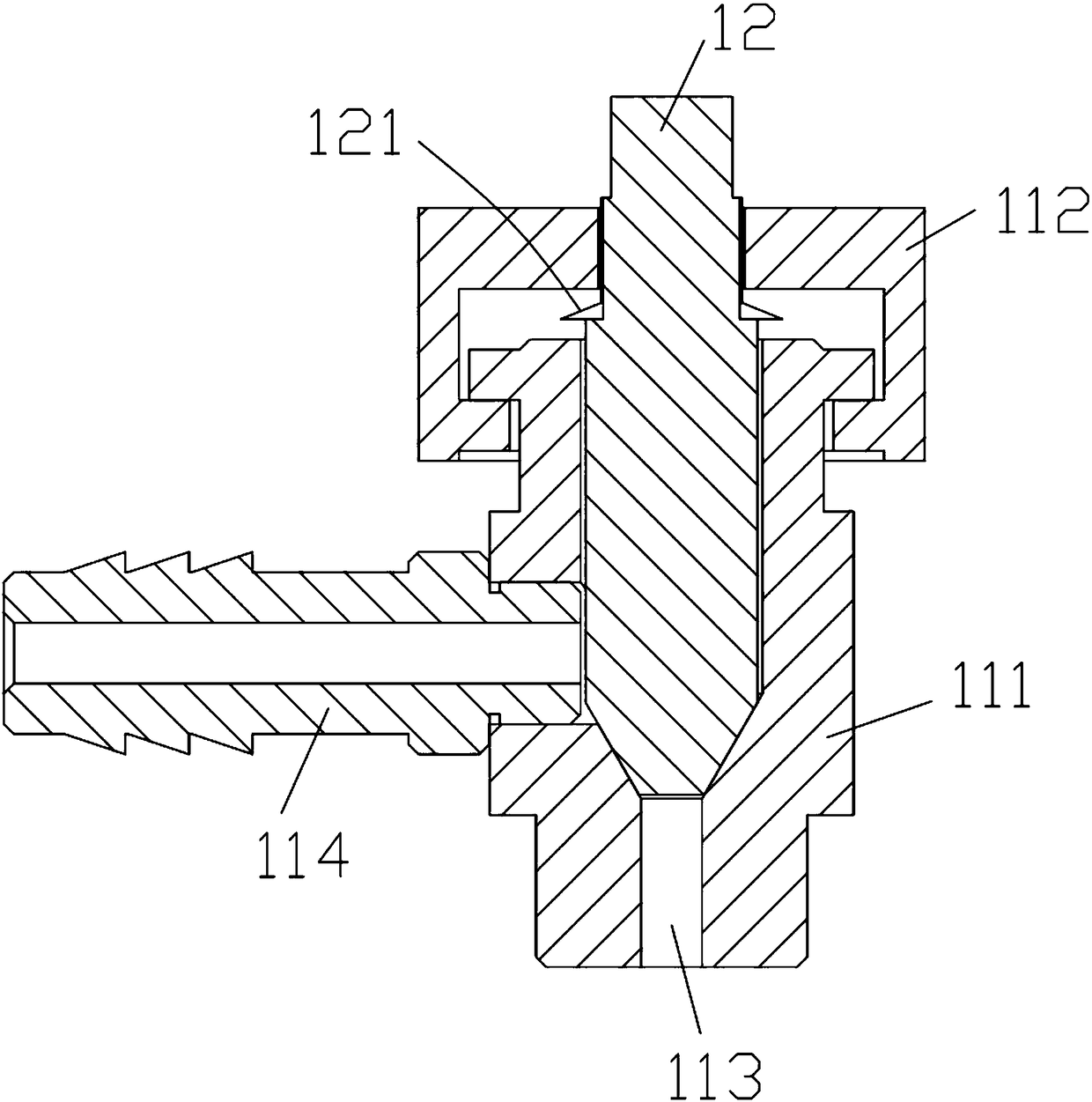

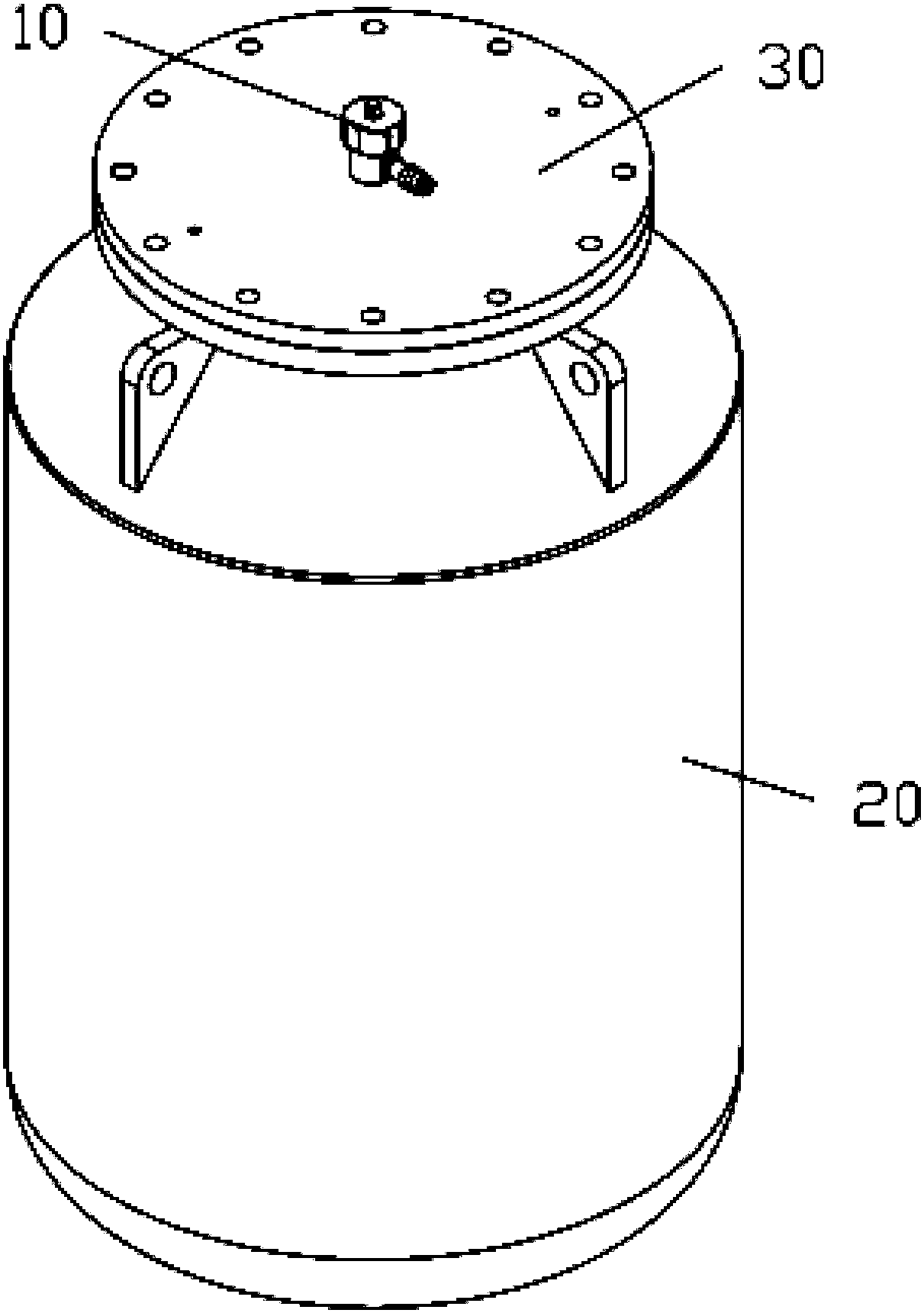

[0031] see Figures 1 to 10 , the embodiment of the present invention provides a high-temperature vacuum sintering furnace internal rotation locking vacuum pumping tank, including a tank body 20, a top cover 30 and an internal rotation vacuum sealing assembly 10 arranged on the top cover 30 and for A wedge connector 40 connecting the upper cover 30 and the tank body 20, the tank body 20 is a sealed tank body 20, a charging port is arranged on the top of the tank body 20, a flange is arranged around the charging port, and the upper cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com