Sunflower combine harvester header test bed

A combine harvester and test bench technology, applied in the field of agricultural machinery, to achieve the effect of convenient adjustment and optimization of structural parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

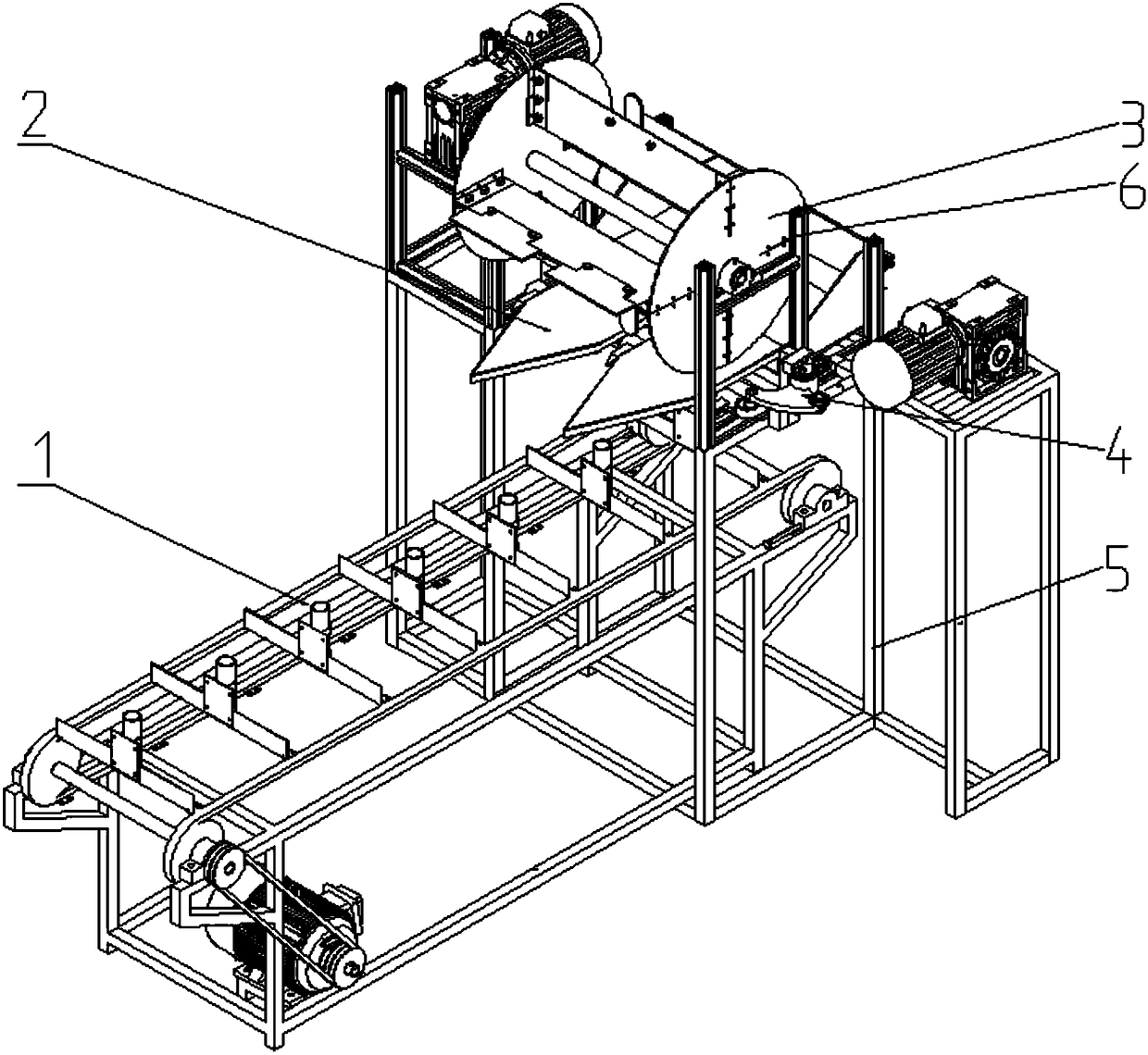

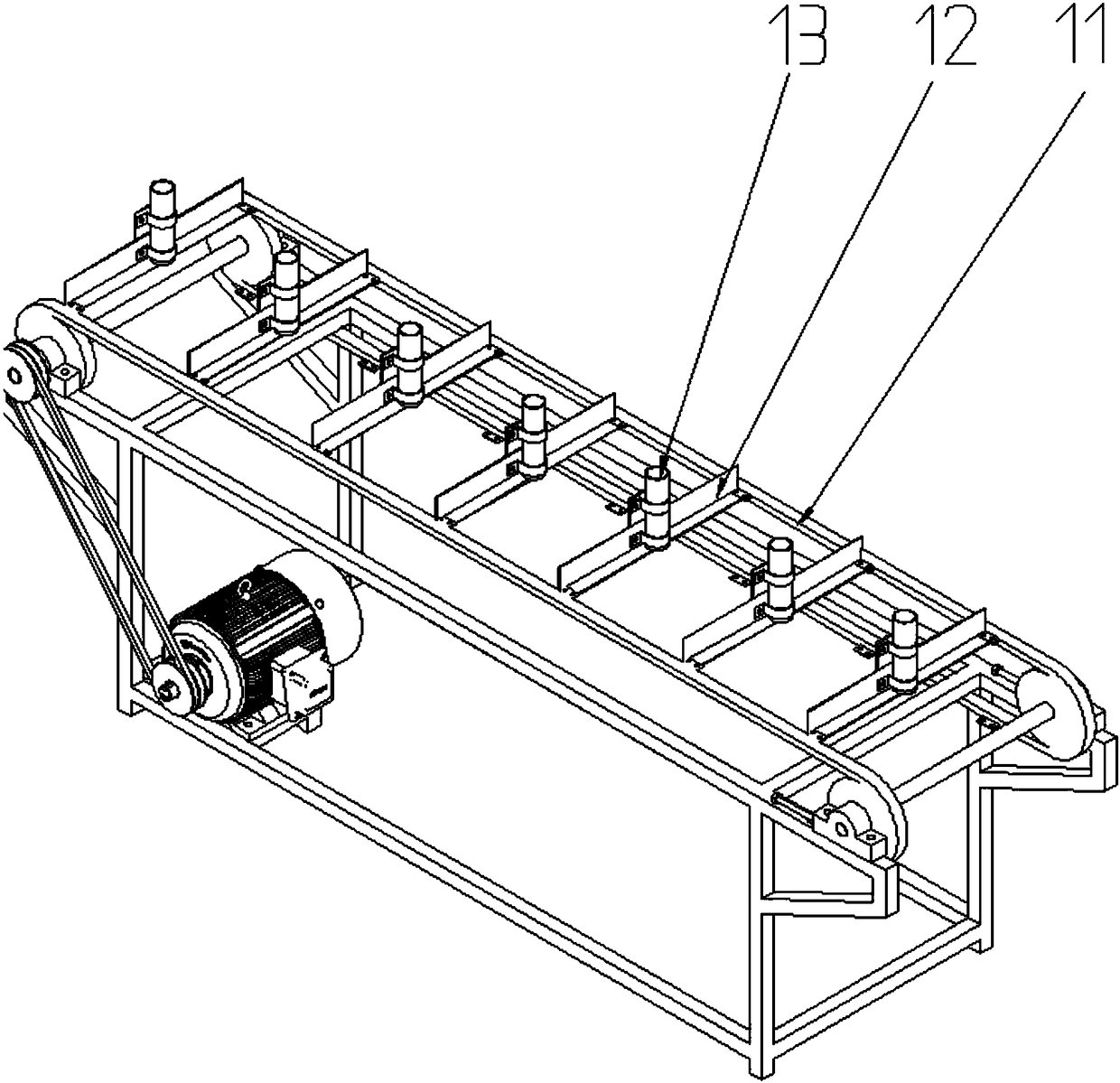

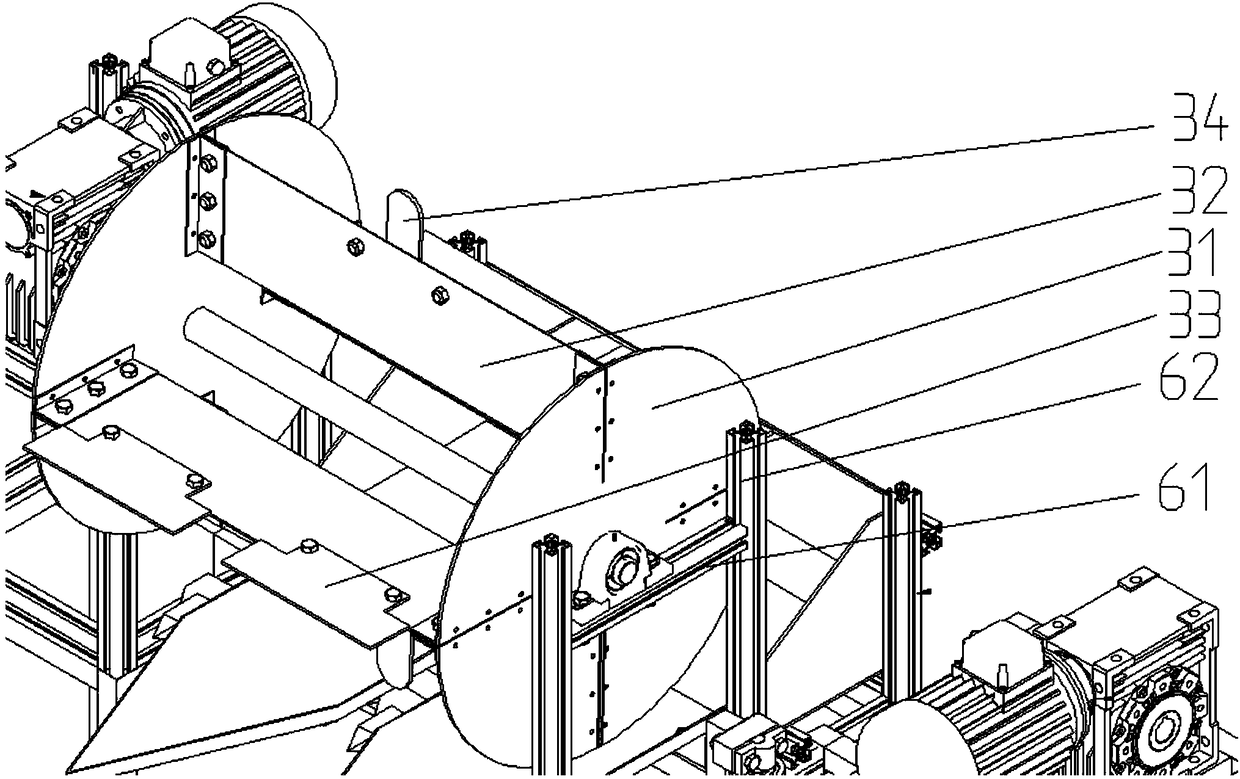

[0022] Such as Figure 1-Figure 4 Shown, a kind of sunflower combine harvester header test bench frame comprises feeding mechanism 1, grain dividing mechanism 2, reel mechanism 3, cutting mechanism 4, frame 5 and controller, and described feeding mechanism 1 is used for passing through Drive plant fixing device to move and plant is transported to cutting mechanism 4, and described plant fixing device is used for placing plant, and described grain dividing mechanism 2, reel mechanism 3 and cutting mechanism 4 are all arranged on the frame 5, and described dividing The grain-splitting mechanisms 2 are arranged at equal intervals and parallel to each other. The gap between adjacent grain-splitting mechanisms 2 is the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com