Technical device for reducing negative frictional resistance on driven cast-in-place pile, and application method thereof

A technology of immersed pipe cast-in-place piles and negative friction resistance, which is applied to sheet pile walls, buildings, infrastructure projects, etc., can solve the problems of asphalt coating groundwater environmental pollution, high construction cost and engineering cost, and difficult plastic casing processing. , to achieve good effect, optimize reinforcement effect and reduce friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings. The protection scope of the present invention is not limited by the description of the present embodiment but by the scope of the claims.

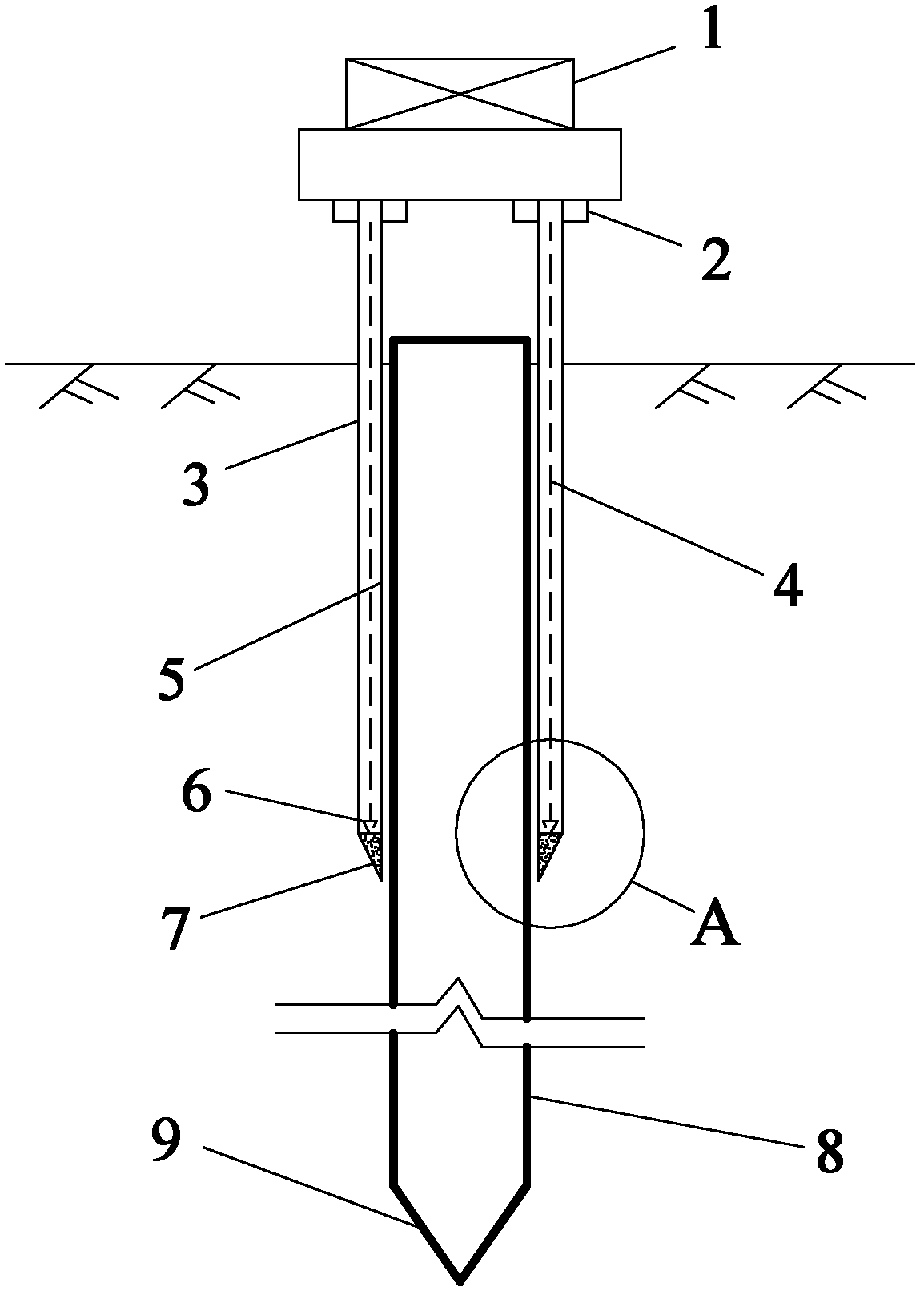

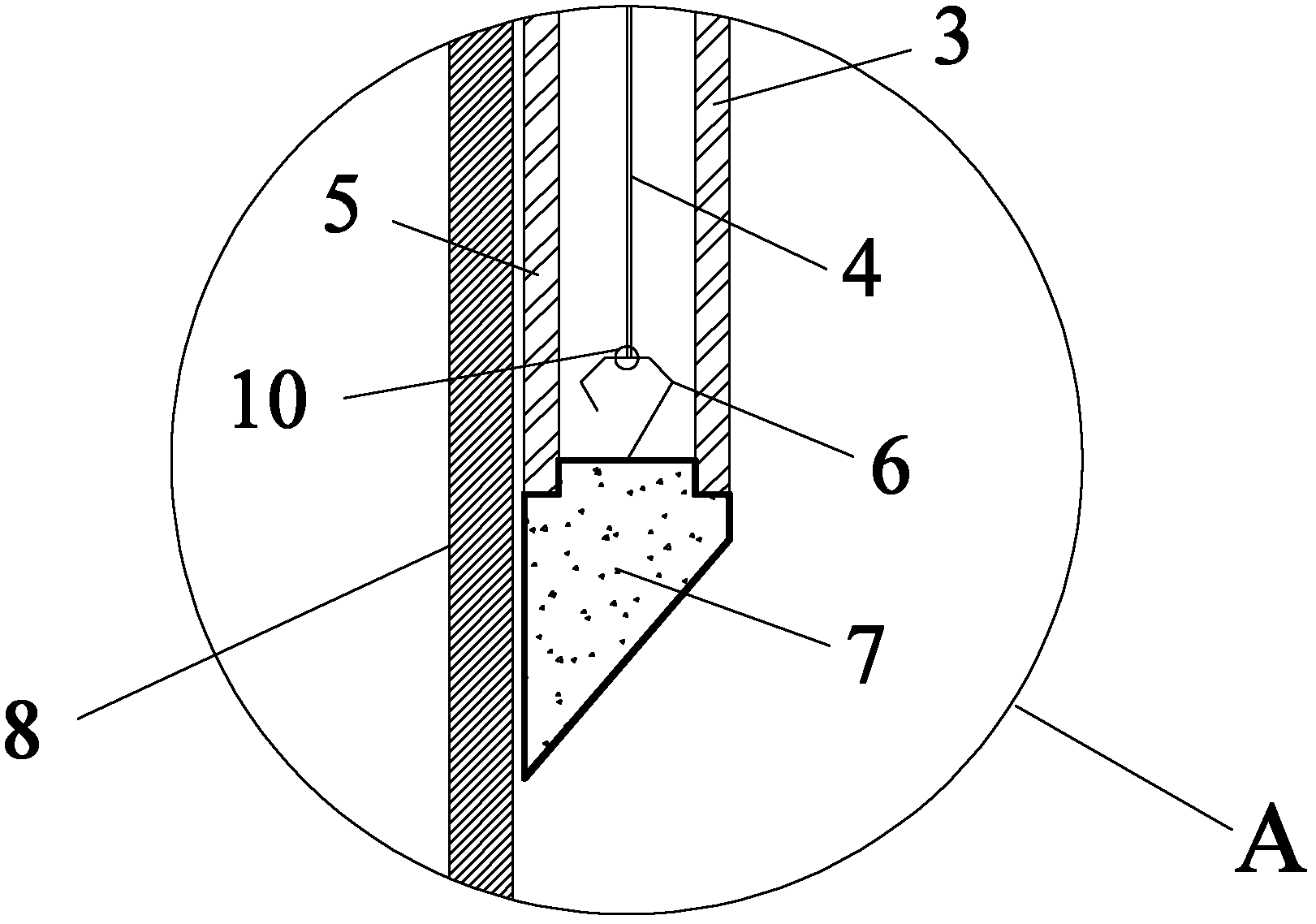

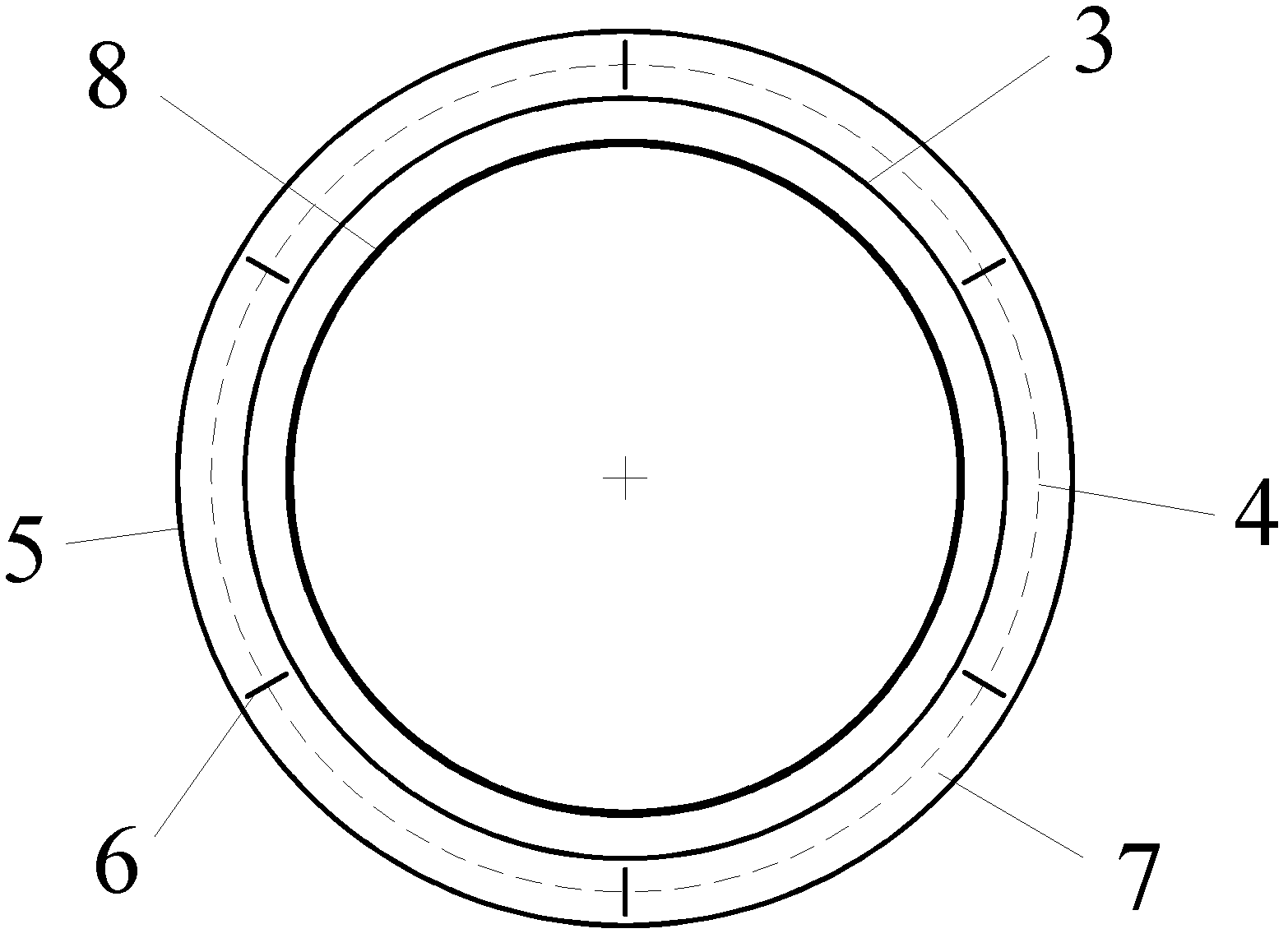

[0029] A technical device for reducing the negative frictional resistance of immersed pipe grouting piles, such as Figure 1~3 As shown, a double-layer steel casing is set outside the pile formwork 8, and the inner steel casing 5 and the outer steel casing 3 marked with scale are connected and fixed below the vibrating hammer 1 through the clamper 2; The lower part is provided with an embedded annular concrete prefabricated body 7 with hook-shaped steel bars 6; the tubular double-layer plastic film 4 is placed between the inner and outer steel sleeves, and is fixed to the annular prefabricated body 7 through the ring buckle 10 on the film on the hooked steel bar 6.

[0030] A me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com