Calibration tray used for seed selection

A technology of tray and test species, which is applied in the field of test species and can solve problems such as change measurement and error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

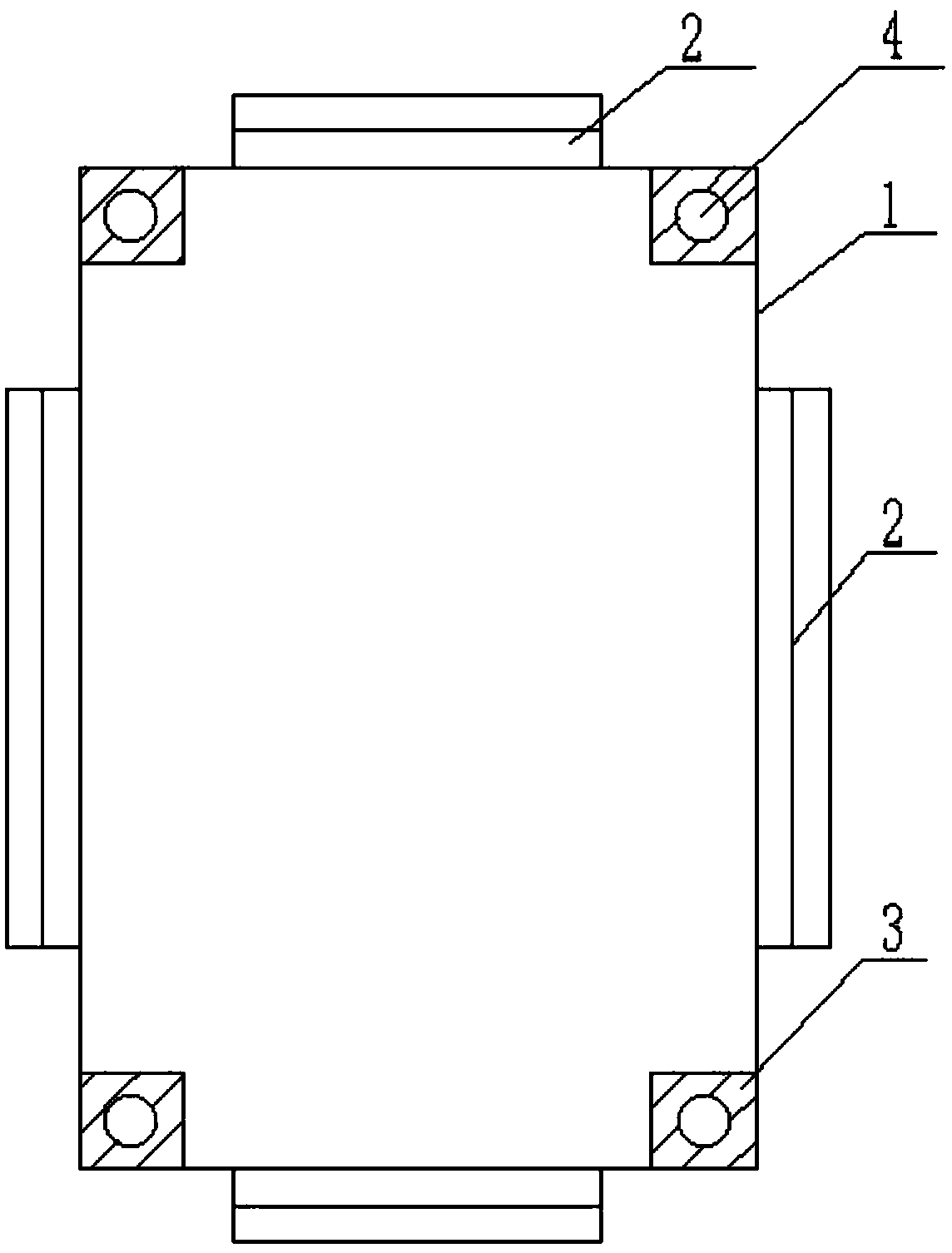

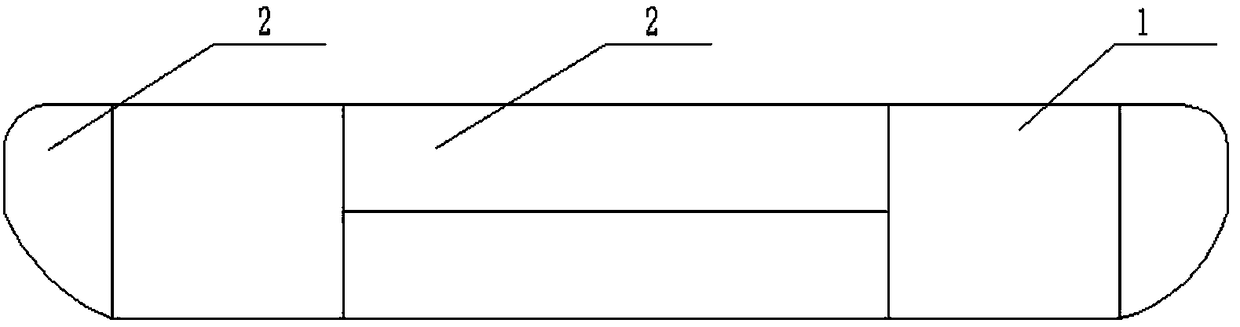

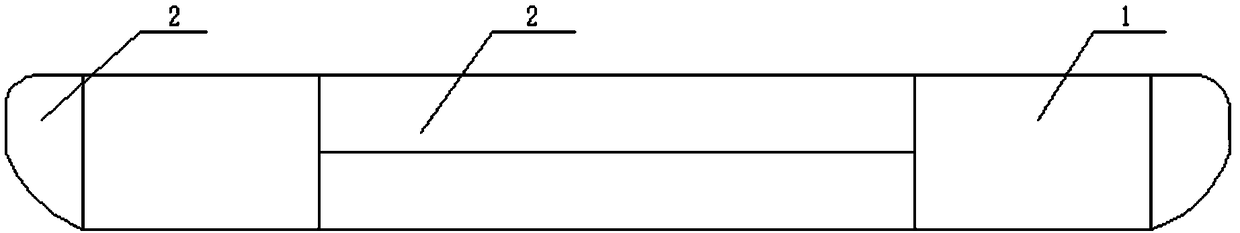

[0027] Such as Figure 1-3 As shown, a calibration tray for species testing includes a tray body 1, the tray body 1 is made of a light-transmitting material, and the tray body 1 is provided with a cavity for containing seeds, and the bottom surface of the cavity is On the horizontal plane, several calibration blocks 3 are arranged in the cavity, and the calibration blocks 3 are made of opaque materials. The outer wall of the tray body 1 is provided with ribs 2, and the ribs 2 are far away from the tray body 1. One end is chamfered.

[0028] The working principle of this embodiment is as follows: the present invention sets a cavity for containing seeds in the tray body 1 made of light-transmitting material, and the bottom surface of the cavity is a horizontal plane, so as to ensure that the seeds can appear closest to the seeds when they are projected. imaging. Set the calibration object directly in the cavity, and the calibration object is made of opaque material to ensure t...

Embodiment 2

[0030] Such as Figure 1-3 As shown, a calibration tray for species testing includes a tray body 1, the tray body 1 is made of a light-transmitting material, and the tray body 1 is provided with a cavity for containing seeds, and the bottom surface of the cavity is On the horizontal plane, a fixed column 4 is vertically arranged in the cavity, and a plurality of calibration blocks 3 are arranged in the cavity, and a through hole matching with the fixed column 4 and penetrating is provided on the described calibration block 3, and the calibration block 3 Through the through hole on the fixed column 4, it is convenient to take and place the fixed block, and also makes the fixed block more stable. The calibration block 3 is made of opaque material. The outer wall of the tray body 1 is provided with a rib 2 , and the end of the rib 2 away from the tray body 1 is chamfered.

Embodiment 3

[0032] Such as Figure 1-3 As shown, this embodiment is further optimized on the basis of Embodiment 1. The cavity in the tray body 1 of the present invention is rectangular, the calibration block 3 is a rectangular block, and the calibration block 3 penetrates through the fixing column through a through hole. 4 and close to the right angle in the cavity, the fixing block is placed on the right angle of the rectangular tray body 1, which not only makes the fixing block more stable, but also avoids placing the seeds on the tray so that the seeds are close to the fixed block, affecting the quality of observation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com