A Method for Identifying Sound Sources Using Single Microphone Movement Combined with Inner Product Operation

A microphone and a single technology, applied in the direction of beacon systems using ultrasonic/sonic/infrasonic waves, etc., can solve the problem of low measurement cost and achieve high resolution and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

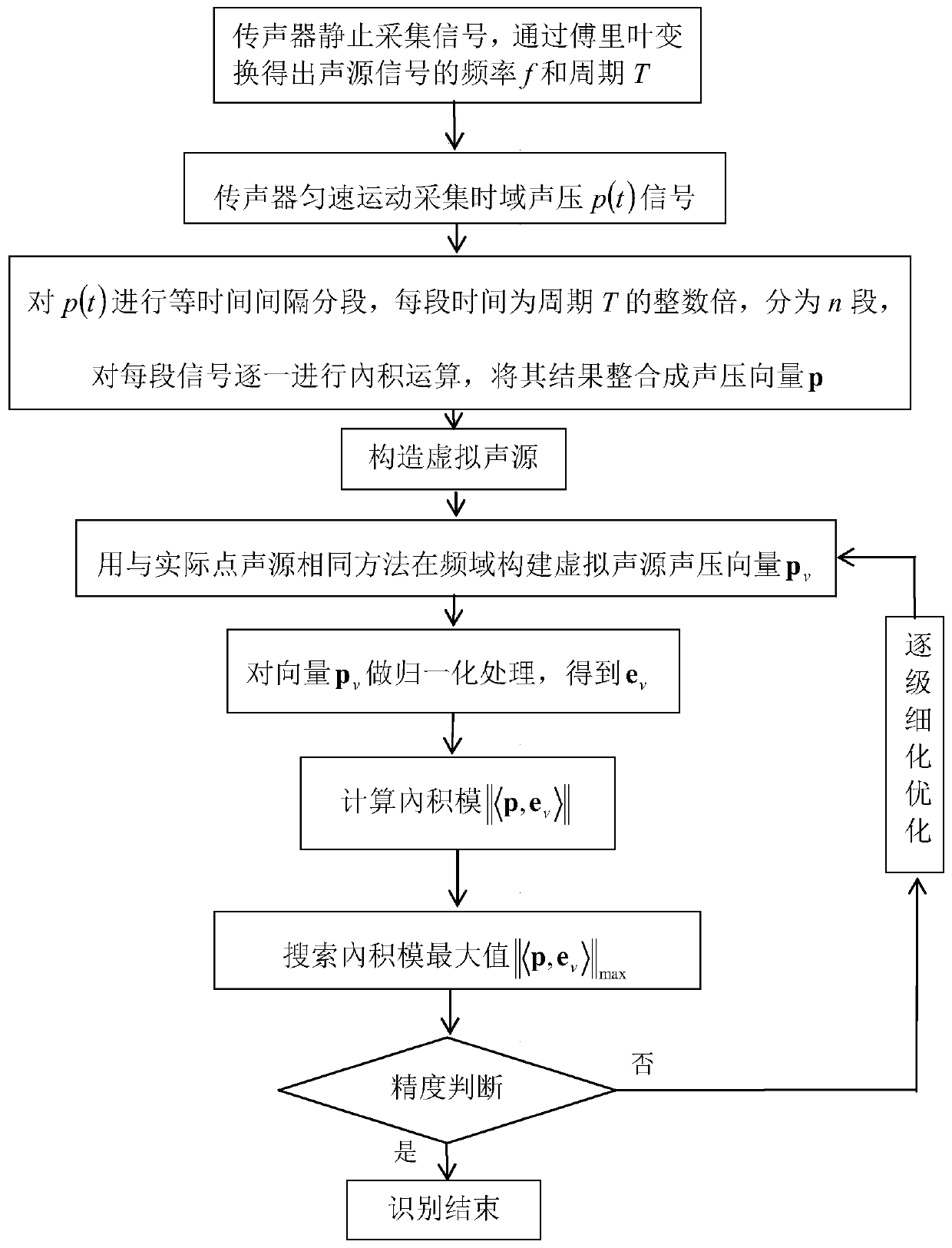

Method used

Image

Examples

Embodiment 1

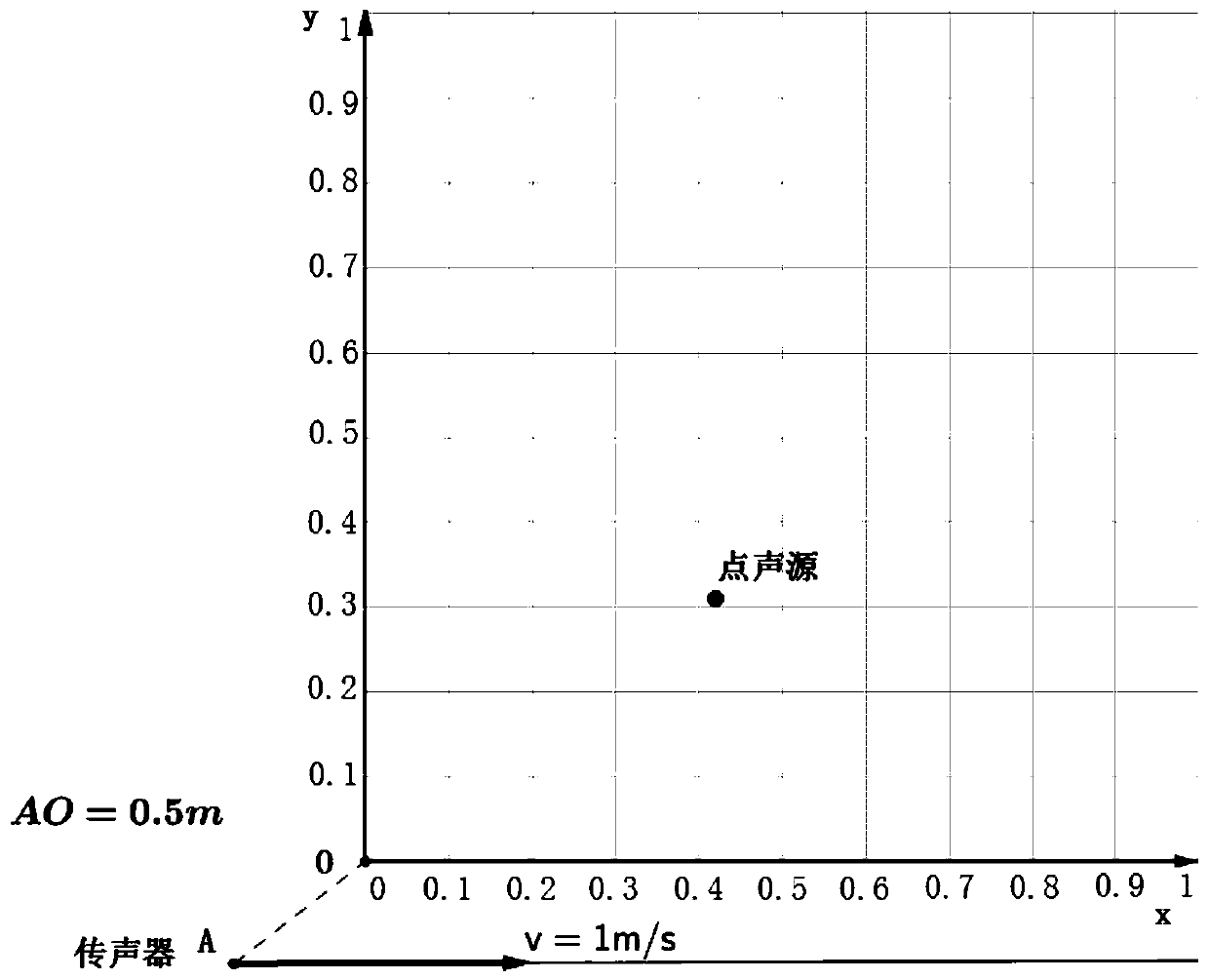

[0059] There is a point sound source in a plane, and the frequency of the radiated sound wave of the point sound source is 1000Hz. Assume that the position coordinates of the point sound source are (0.4226,0.3113), and the coordinate unit is meter, such as figure 1 As shown, the recognition accuracy is required to reach the millimeter level. The identification steps are as follows:

[0060] (1) Detection of sound source frequency

[0061] Place the microphone at a point outside the plane, and take AO=0.5m away from the plane. First, the microphone is static, and the sound pressure signal is collected, and Fourier transform is applied to the collected signal to obtain the frequency f=1000Hz and period T=0.001s of the sound wave of the sound source.

[0062] (2) The microphone moves at a uniform speed to collect sound pressure signals

[0063] Let the microphone move in a straight line at a uniform speed along the X-axis, set the moving speed as v=1m / s, and collect a time-dom...

Embodiment 2

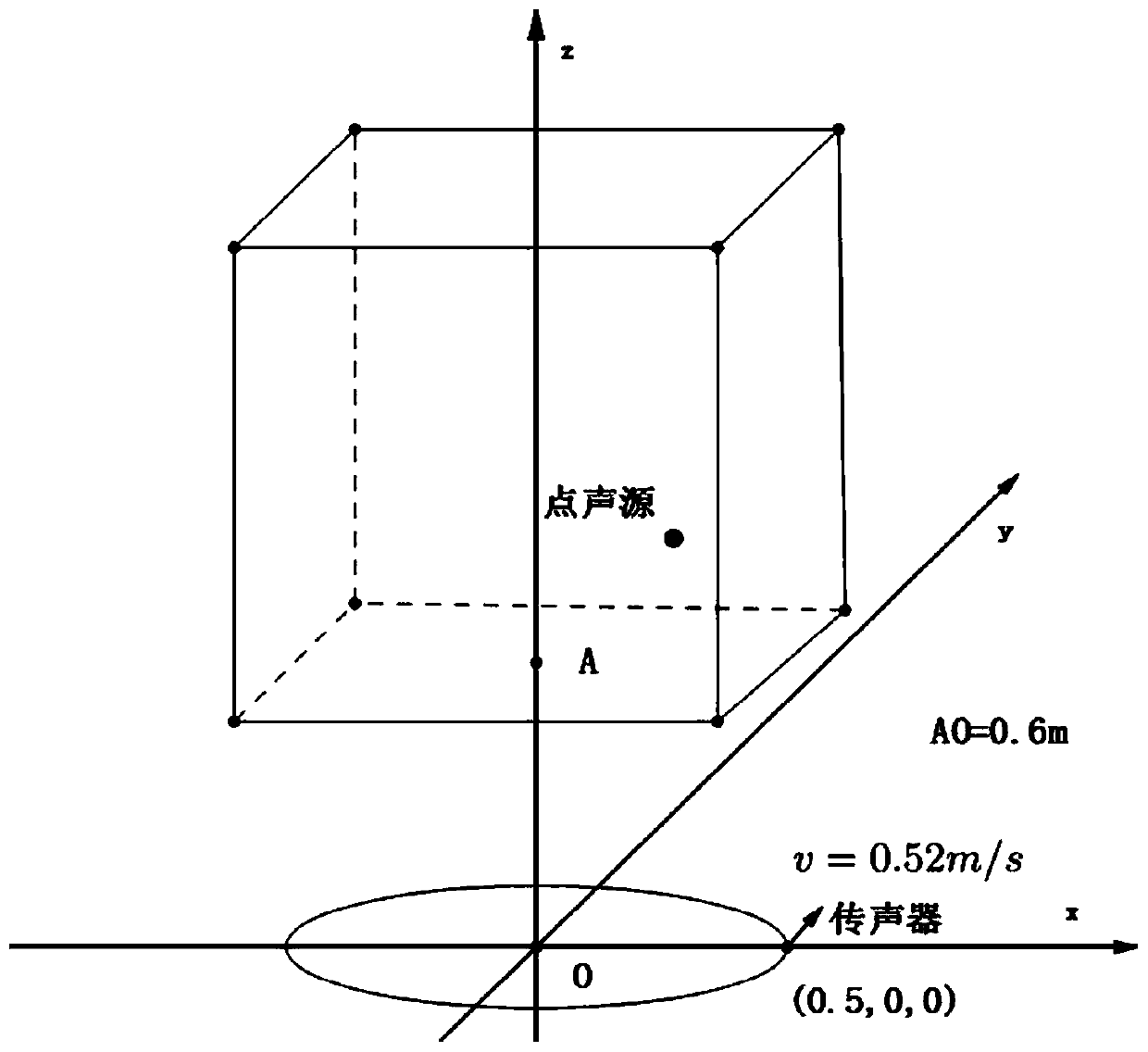

[0081] There is a sound source at a certain point in space, and the radiated sound wave frequency of the sound source is 800Hz. Assume that the coordinates of the sound source in the space are (0.2123, 0.3558, 0.7912), and the coordinate unit is meter, such as figure 2 As shown, the recognition requirement reaches the millimeter level. The identification steps are as follows:

[0082] (1) Detection of sound source frequency

[0083] The initial position of the microphone is taken as (0.5, 0, 0), and the distance from the area where the sound source is located is AO=0.6m. First, the microphone is static, and the sound pressure signal is collected, and Fourier transform is applied to the collected signal to obtain the frequency f=800Hz and period T=0.00125s of the sound wave of the sound source.

[0084] (2) The microphone moves at a uniform speed to collect sound pressure signals

[0085] Let the microphone move at a constant speed along the set circular track on the plane ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com