Fracture-hole detection system and detection method while drilling based on nano-magnetic fluid drilling fluid

A nano-magnetic fluid and detection system technology, which is applied in the field of petroleum drilling engineering, can solve the problems of inability to effectively evaluate the size, cracks, karst cave development zones and their connection relationship cannot be detected, etc., and achieve the effect of enhancing the magnetic field strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

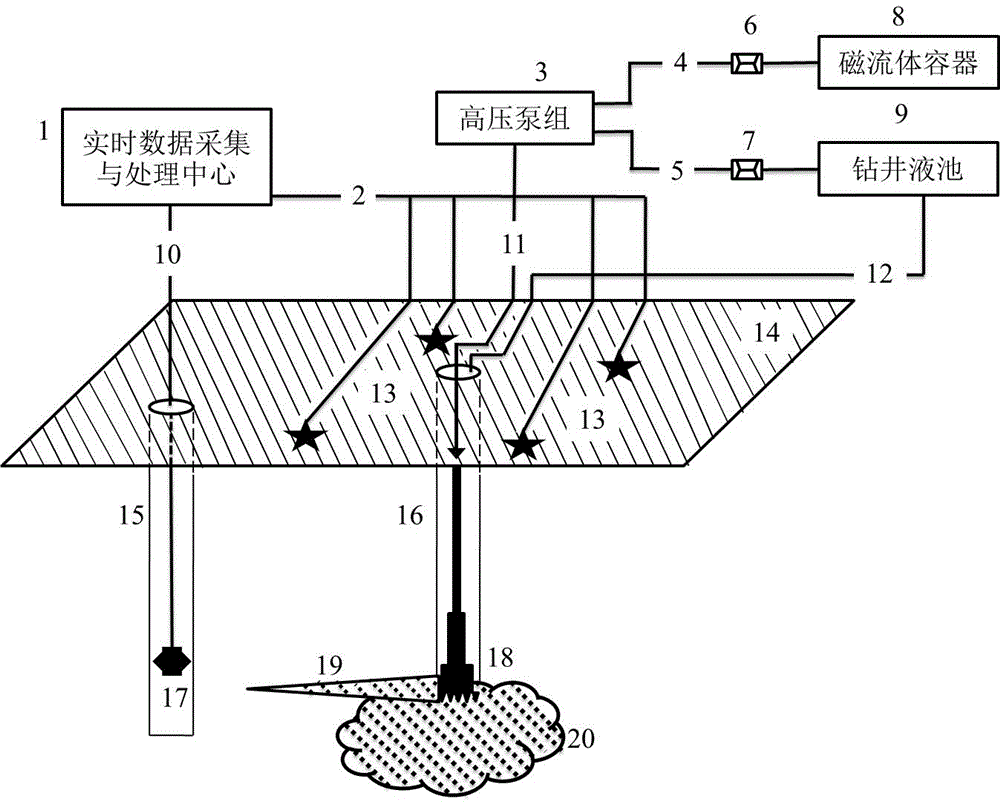

[0033] Such as figure 1As shown, the fracture-cavity detection system based on nano-magnetic fluid drilling fluid includes: real-time data acquisition and processing center 1, surface magnetometer and real-time data acquisition and processing center communication line 2, high-pressure pump set 3, and the first delivery pipeline 4. The second delivery pipeline 5, the first control valve 6, the second control valve 7, the magnetic fluid container 8, the drilling fluid pool 9, the adjacent well external magnetic field generator control pipeline 10, the third delivery pipeline 11, and the drilling fluid return pipeline 12. Surface magnetometer 13, external magnetic field generator 17 for adjacent wells.

[0034] The nano-magnetic fluid is stored in the magnetic fluid container 8, and the nano-magnetic fluid is a stable colloidal liquid composed of a base carrier liquid, a surfactant, and magnetic solid particles with nanometer-scale diameters. Nano-scale magnetic solid particles ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com