Intelligent flattening device of grain depot

An intelligent and grain depot technology, applied in the field of granary machinery, can solve the problems of wasting labor force, large area of granary, and large volume of grain unclosing device, so as to achieve obvious effect of unwinding, save labor and reduce manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

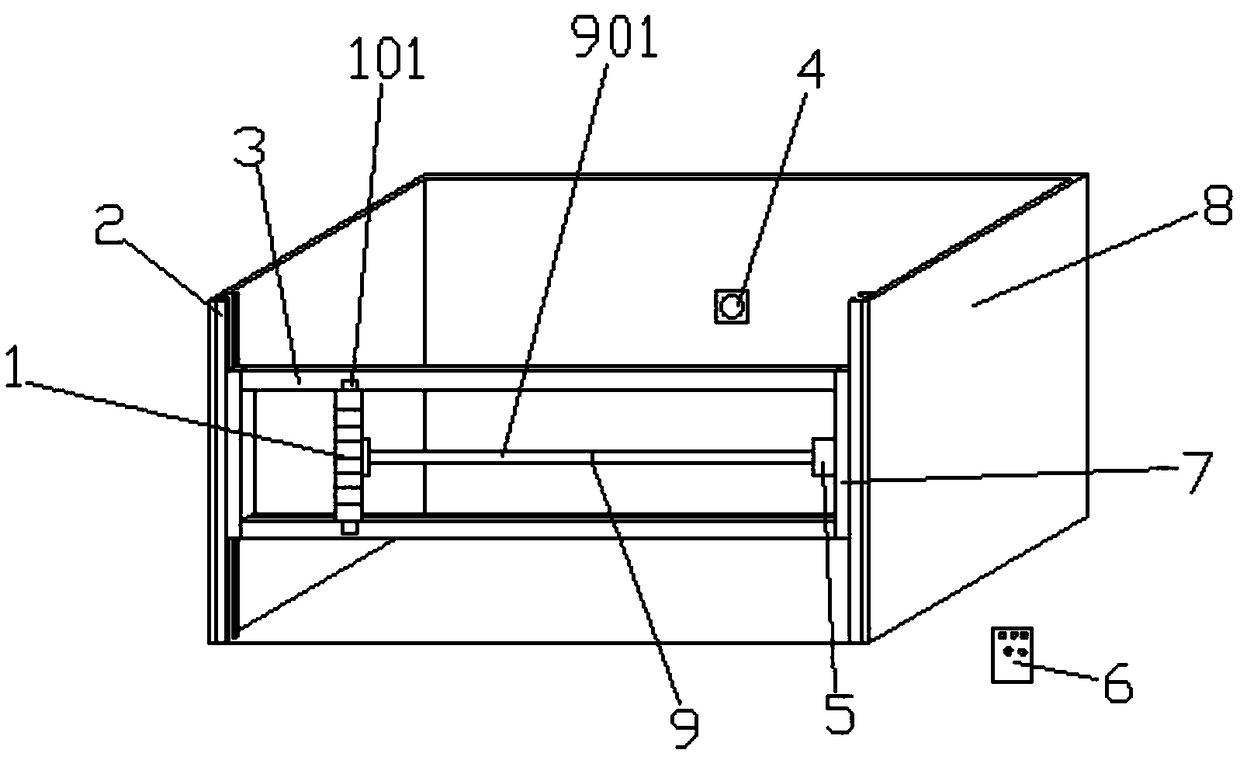

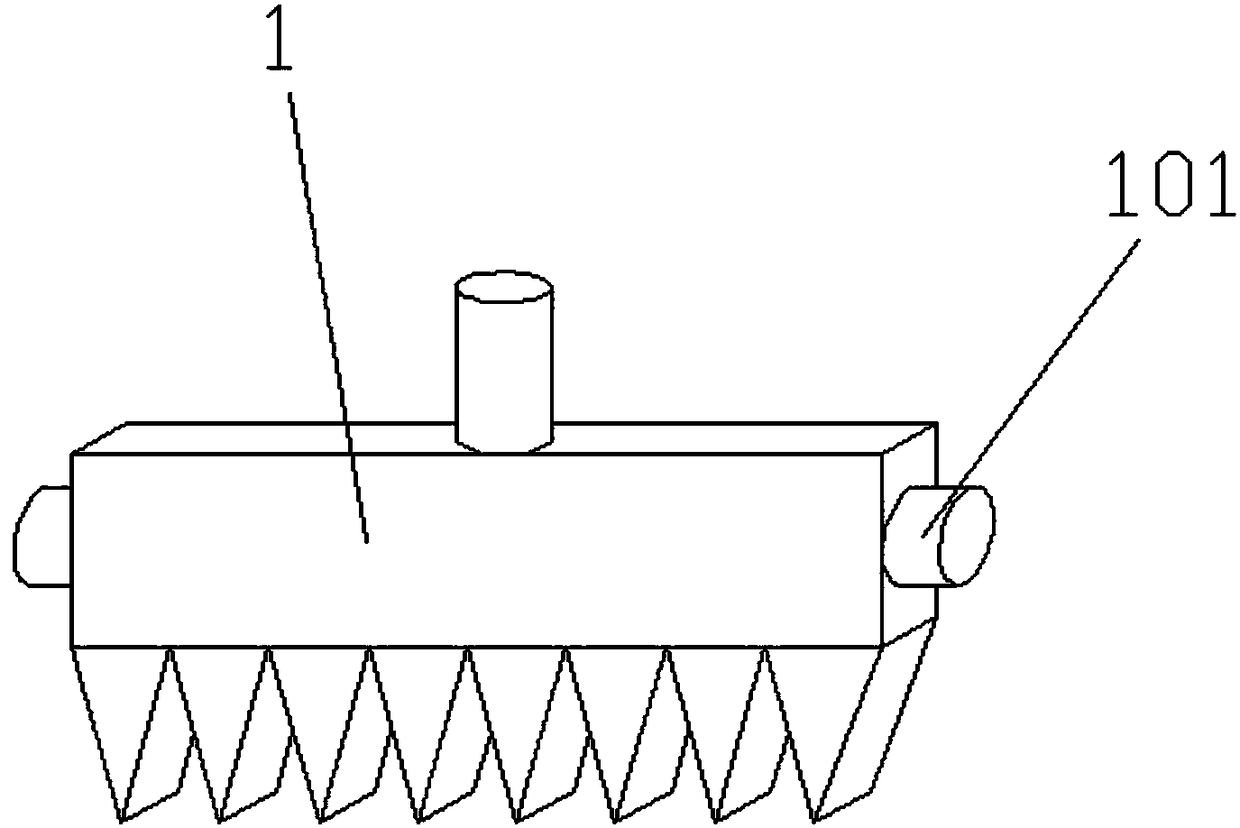

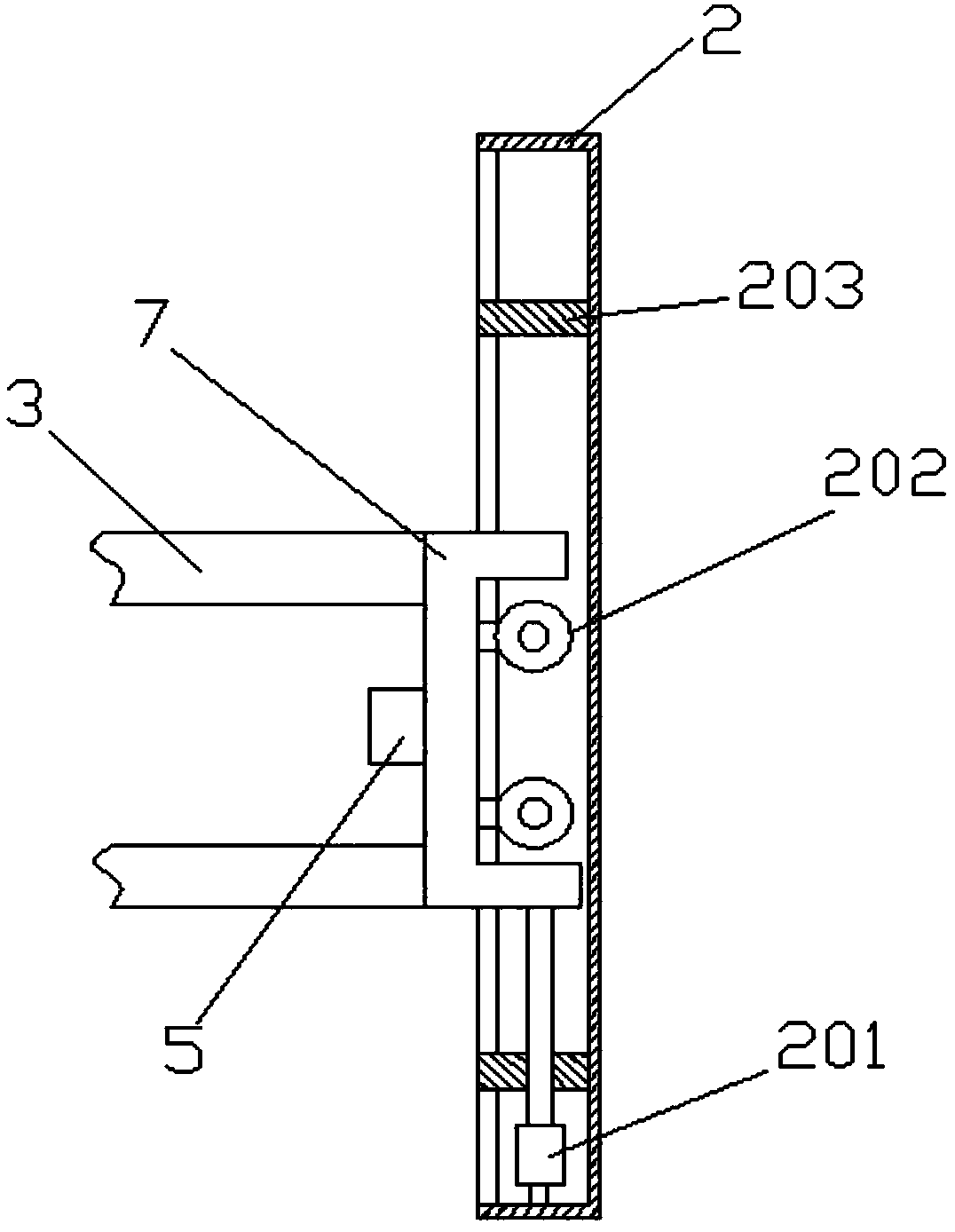

[0032] Such as figure 1 , 5 As shown, a grain depot intelligent closing device is characterized in that it includes: a closing steel plate 1, a liftable slide rail 2, a horizontal slide rail 3, a camera in the warehouse 4, a remote control receiving terminal 5, a hand-held remote control 6, a load-bearing Steel beam 7, detachable connecting shaft 9, described liftable slide rail 2 is provided with two groups, and described two groups of liftable slide rails 2 are vertically fixed on the walls 8 on both sides by expansion nails respectively, the two sides The plane formed by the liftable slide rails 2 is perpendicular to the walls on both sides. There are two load-bearing steel beams 7, which are respectively installed on the liftable slide rail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com