Mechanism reliability modeling method

A technology of reliability and analysis methods, applied in random CAD, computer-aided design, special data processing applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

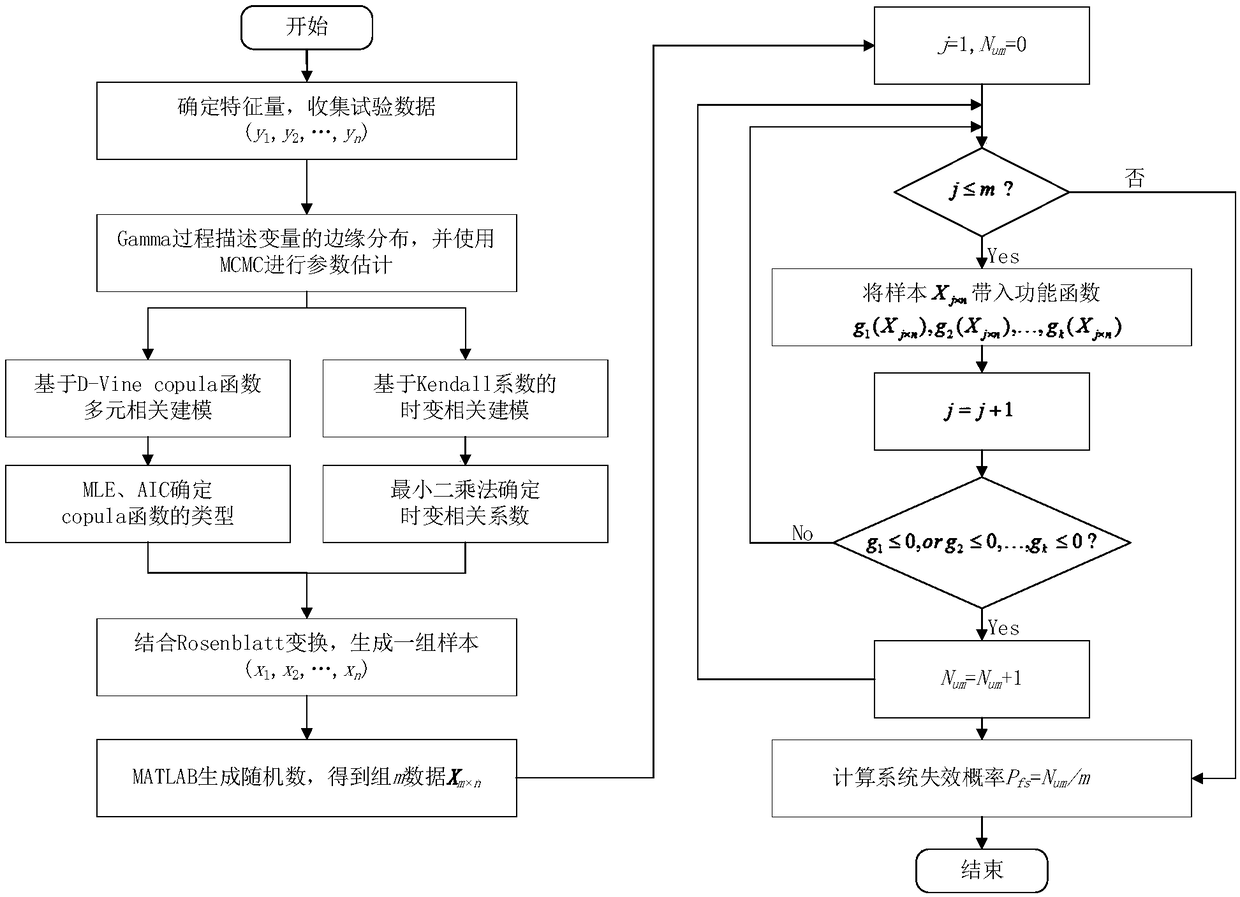

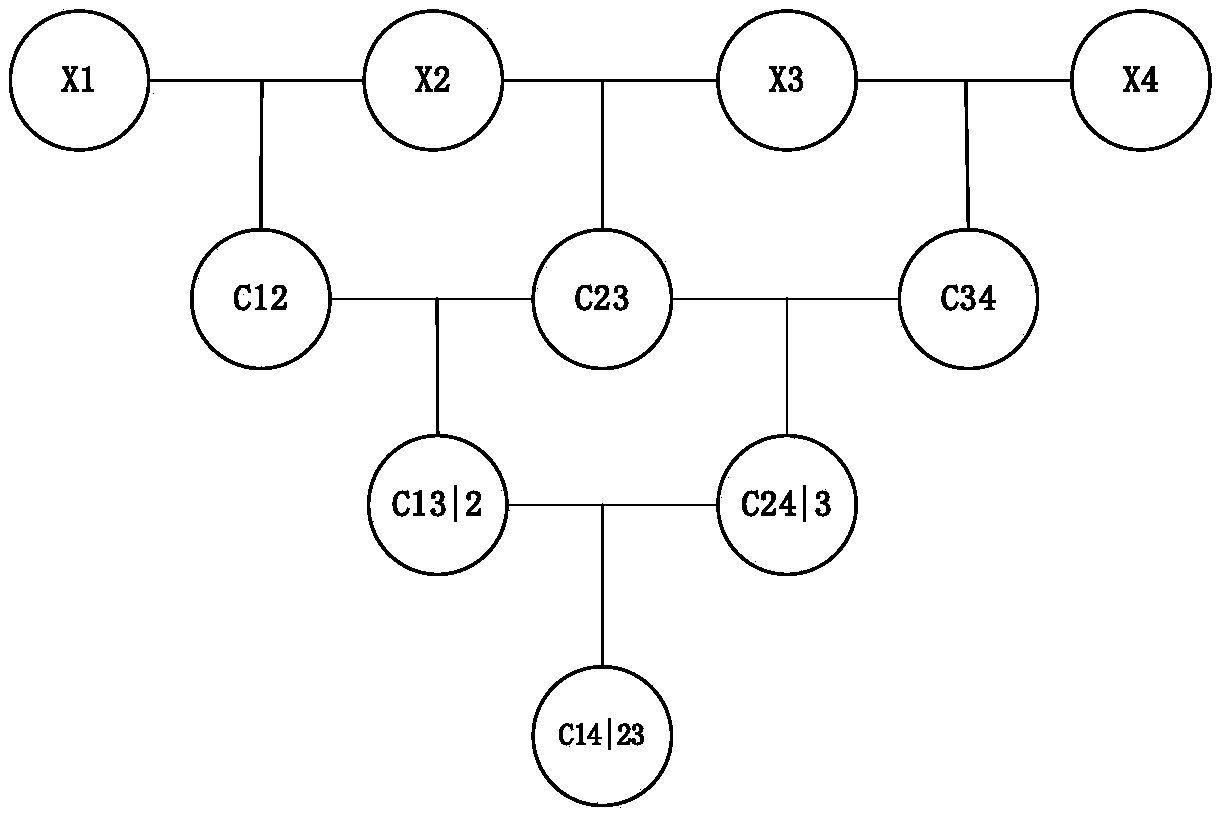

Method used

Image

Examples

Embodiment Construction

[0051] The embodiments will be described in detail below in conjunction with the accompanying drawings.

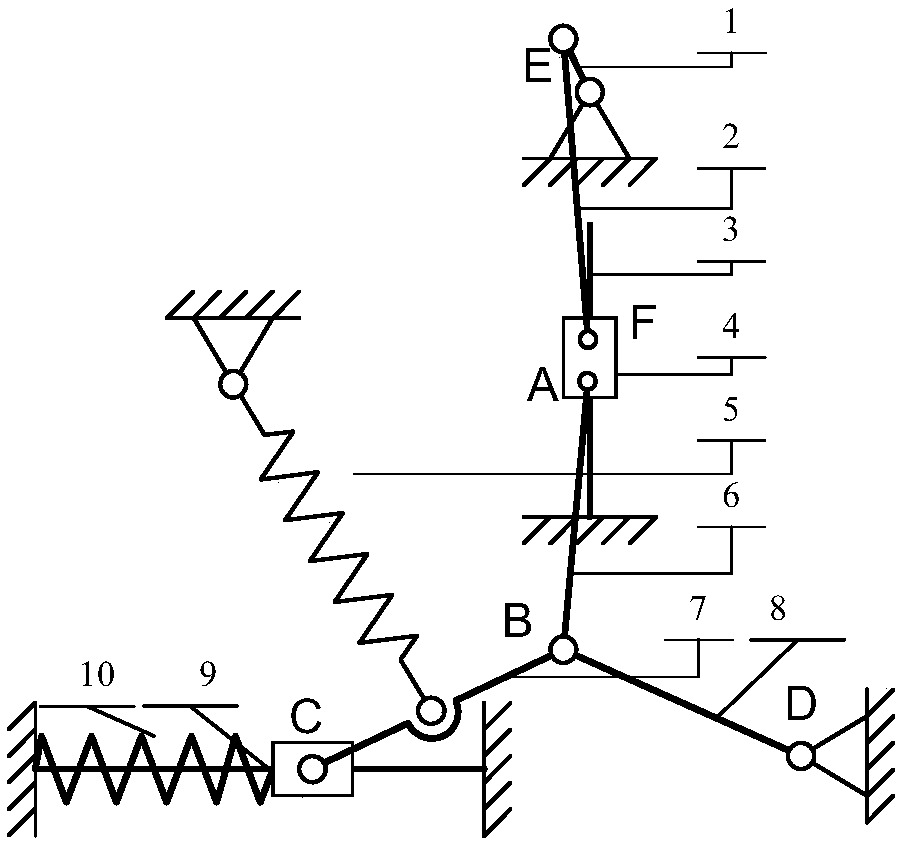

[0052] Taking an aircraft cabin door lock test mechanism as an example, image 3 It is a schematic plan view of the upper lock test mechanism of the cabin door. The movement of the displacement slider 9 is used to simulate the movement of the lock hook, and the servo motor and slider crank mechanism are used to drive the slider 4 to move vertically on the guide rail. It is transmitted to the displacement slider 9 through the connecting rod assembly, so that it can move horizontally along the guide rail. The connecting rod assembly is a set of planar connecting rod mechanism, which is used to transmit the driving force on the driving slider 4 to the displacement slider 9, and ensure the coordination of the motion relationship between the two sliders. The external load acting on the displacement slider 9 is simulated by an externally loaded spring 10 .

[0053] Step 1: Ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com