Analysis method for collapsing force of two common steel rectangular-section thin-wall beams under symmetric mode

A technology of rectangular section and analysis method, applied in special data processing applications, instruments, geometric CAD, etc., can solve problems such as lack of geometric models, failure to use thin-walled beam crush performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0156] The present invention is described in detail below in conjunction with accompanying drawing:

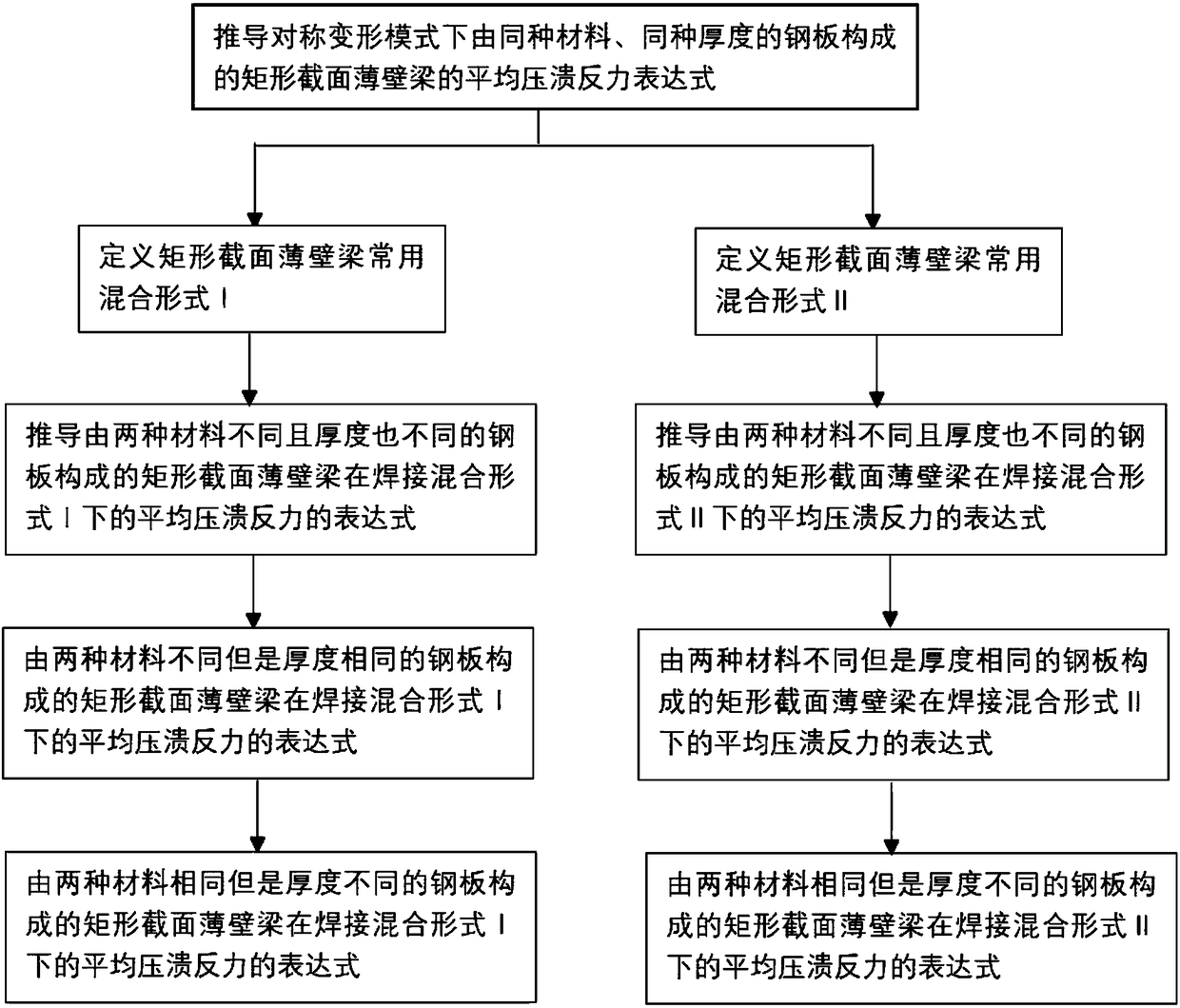

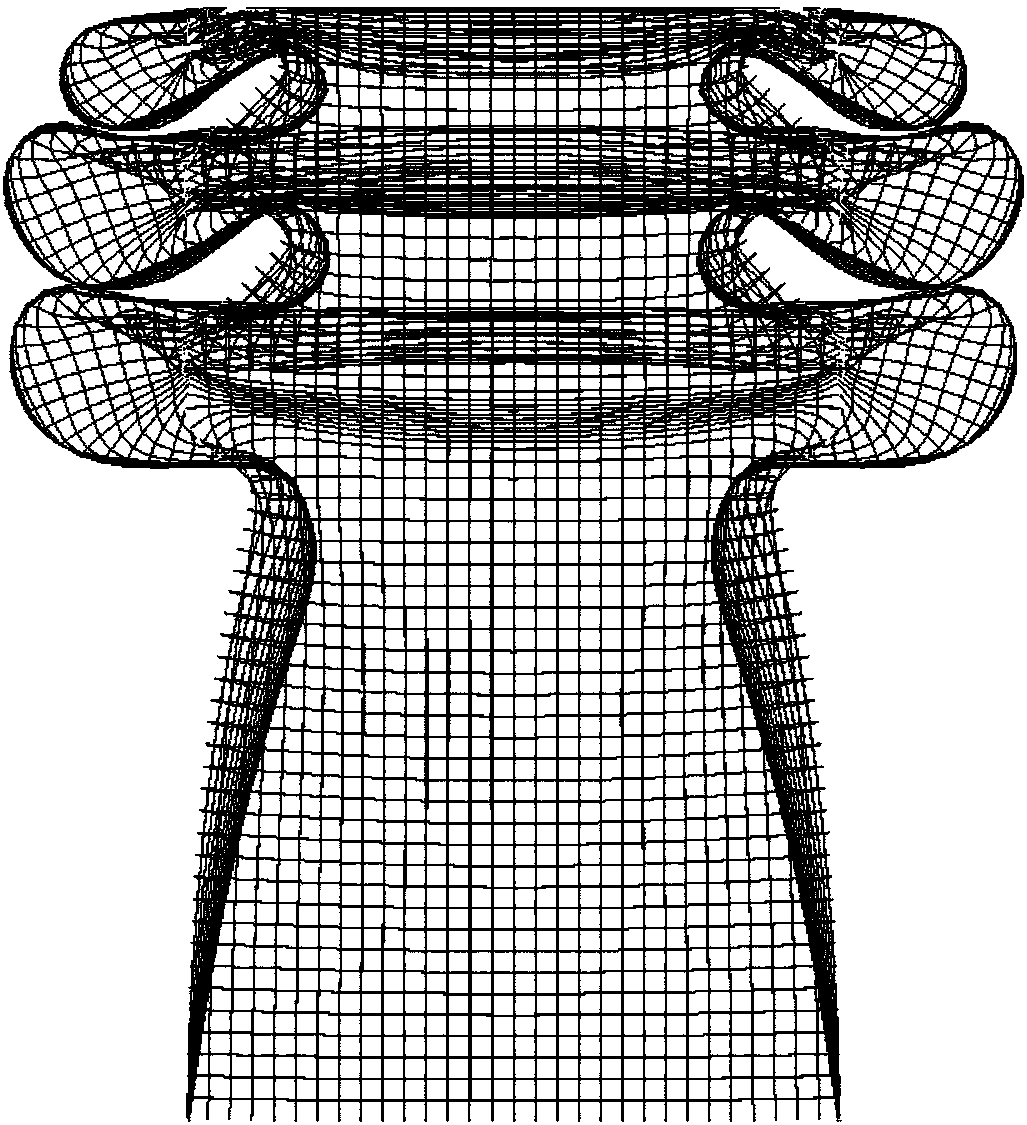

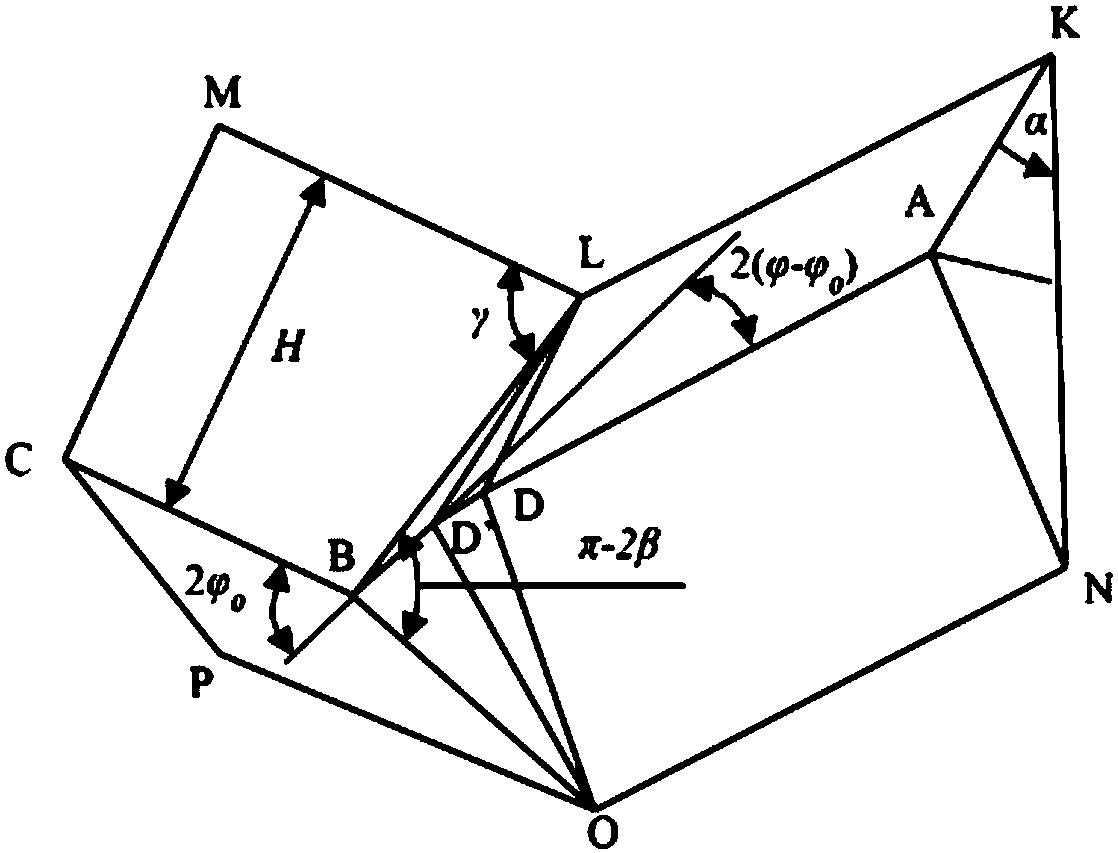

[0157] In the method for analyzing the crushing force of two commonly used steel rectangular cross-section thin-walled beams under the symmetric mode described in the present invention, firstly, by calculating the width-to-thickness ratio of a rectangular cross-section thin-walled beam made of steel plates of the same material and thickness, the axial In the stable symmetrical deformation mode in the process of vertical crushing, the expression of the average crushing force is derived by using the principle of energy conservation and plastic mechanics; then, considering the mixed form and welding position, the steel plate with two different materials and different thicknesses is defined , Two mixed forms of thin-walled beams with rectangular cross-section welded by two steel plates of different materials but of the same thickness and welded by two steel plates of the same mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com