A composite material antisymmetrical wrapping square tube crushing characteristic analysis method

A composite material and characteristic analysis technology, which is applied in special data processing applications, instruments, geometric CAD, etc., can solve problems such as the lack or inability to use finite element methods or test methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

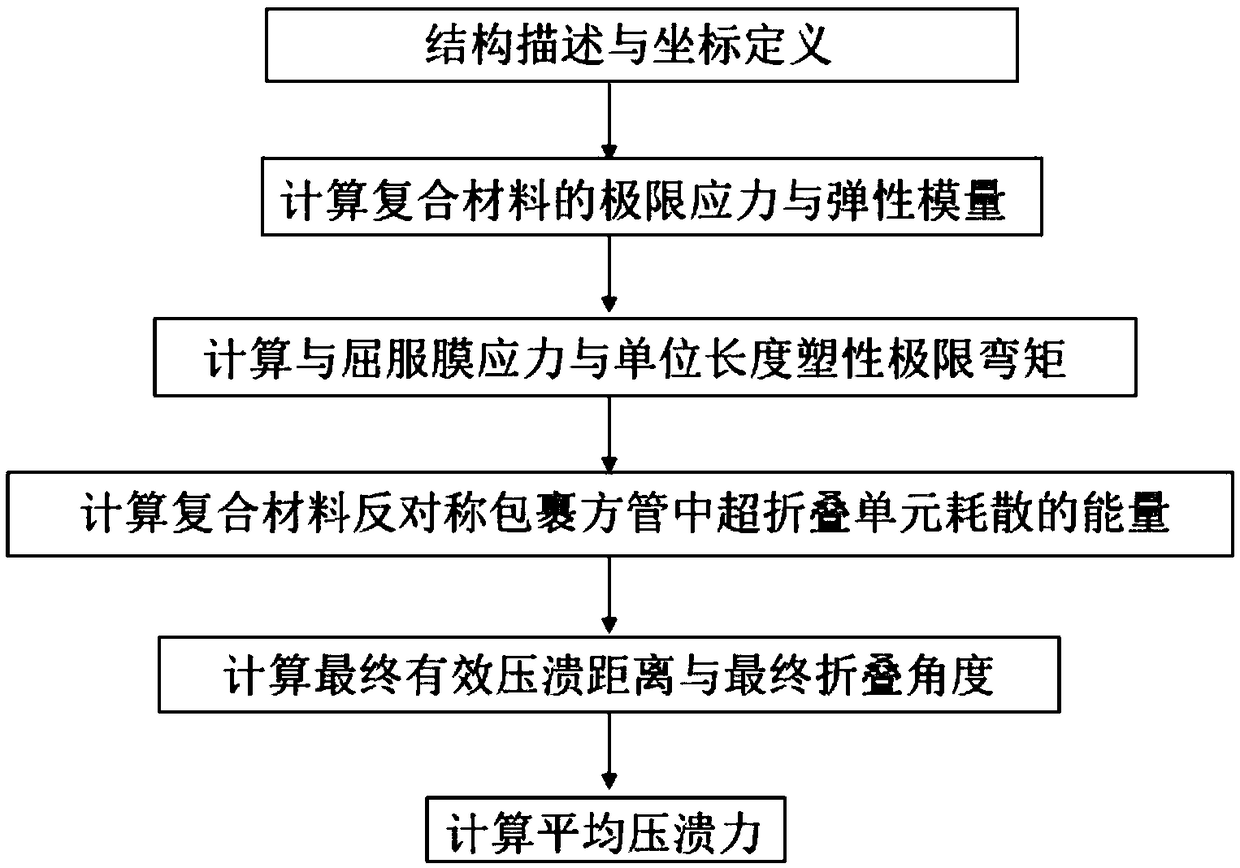

Method used

Image

Examples

Embodiment

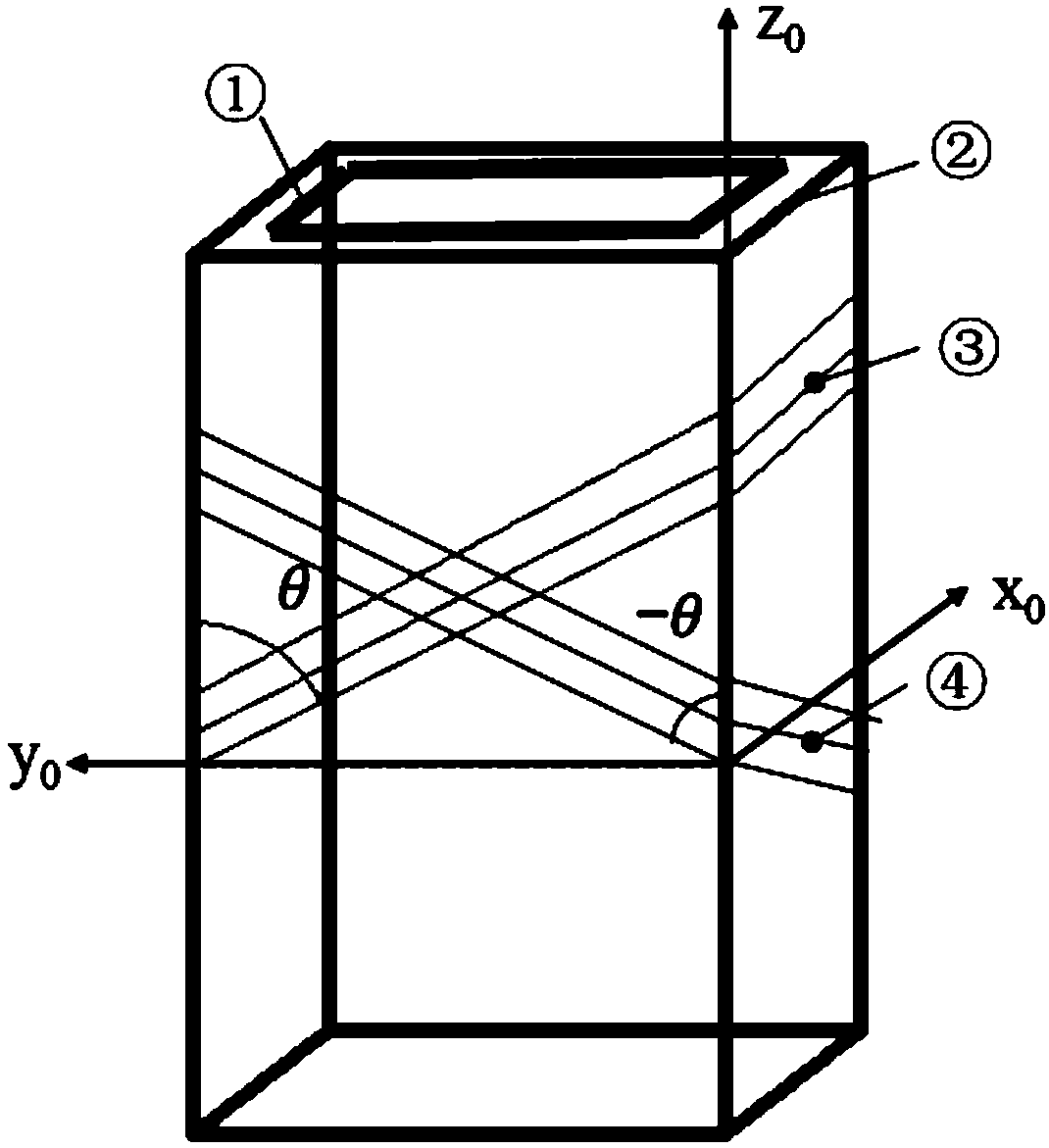

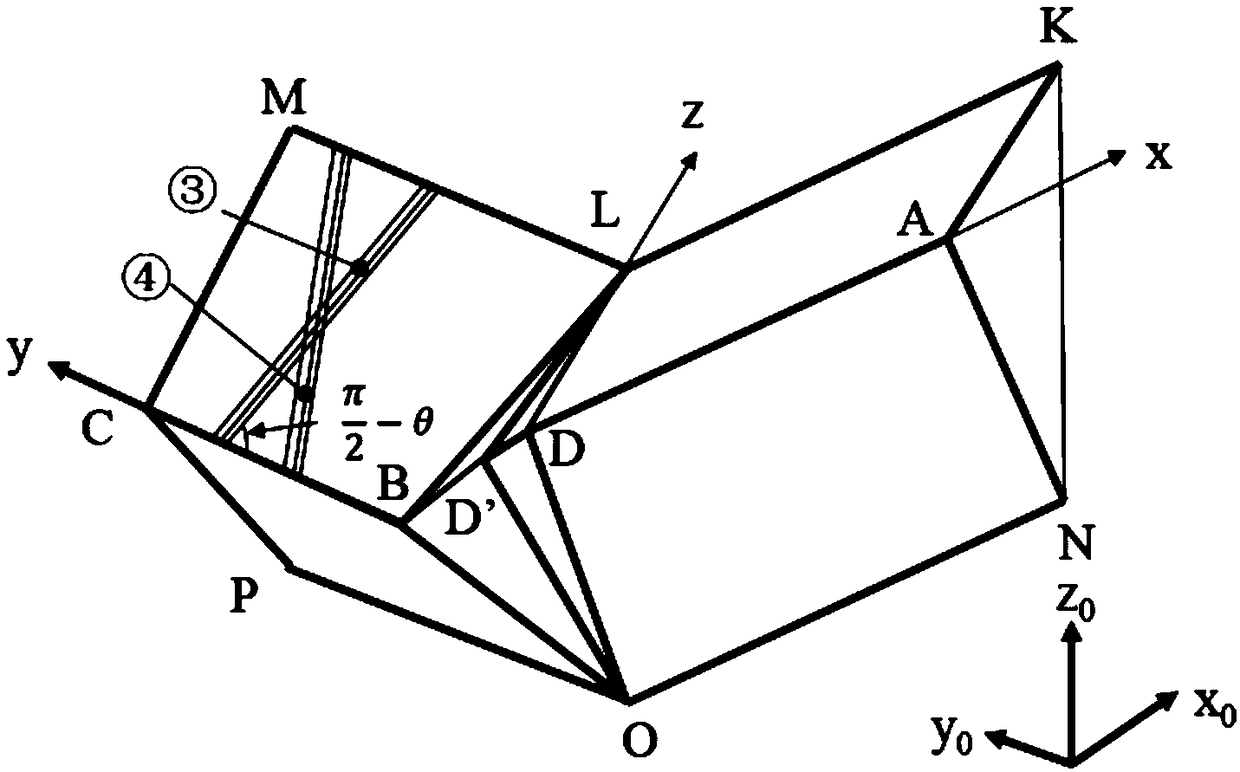

[0219] Next, the present invention introduces the method for analyzing the crushing characteristics of the fiber-reinforced composite material antisymmetrically wrapped square pipe proposed by the present invention in conjunction with the examples.

[0220] In the embodiment, the metal material wrapping the square tube is 6063-T5, the side length is 25mm, and the thickness is 1.6mm. The flow stress σ of the metal m =140MPa; the selected composite material is glass fiber epoxy resin composite material, the composite material is Type 30 glass fiber, and the matrix is 820 epoxy resin. The performance parameters of the composite material are shown in Table 1. The wrapped glass fiber is 2 layers, namely [45 / -45], the thickness of the composite material is h c = 1.27 mm.

[0221] Load boundary conditions see Image 6 , ⑥ is a rigid body with a downward moving speed of V, and ⑦ is a metal square tube wrapped in composite material.

[0222] Table 1 Performance parameters of glass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com