Curtain grouting three-dimensional visualization model construction method

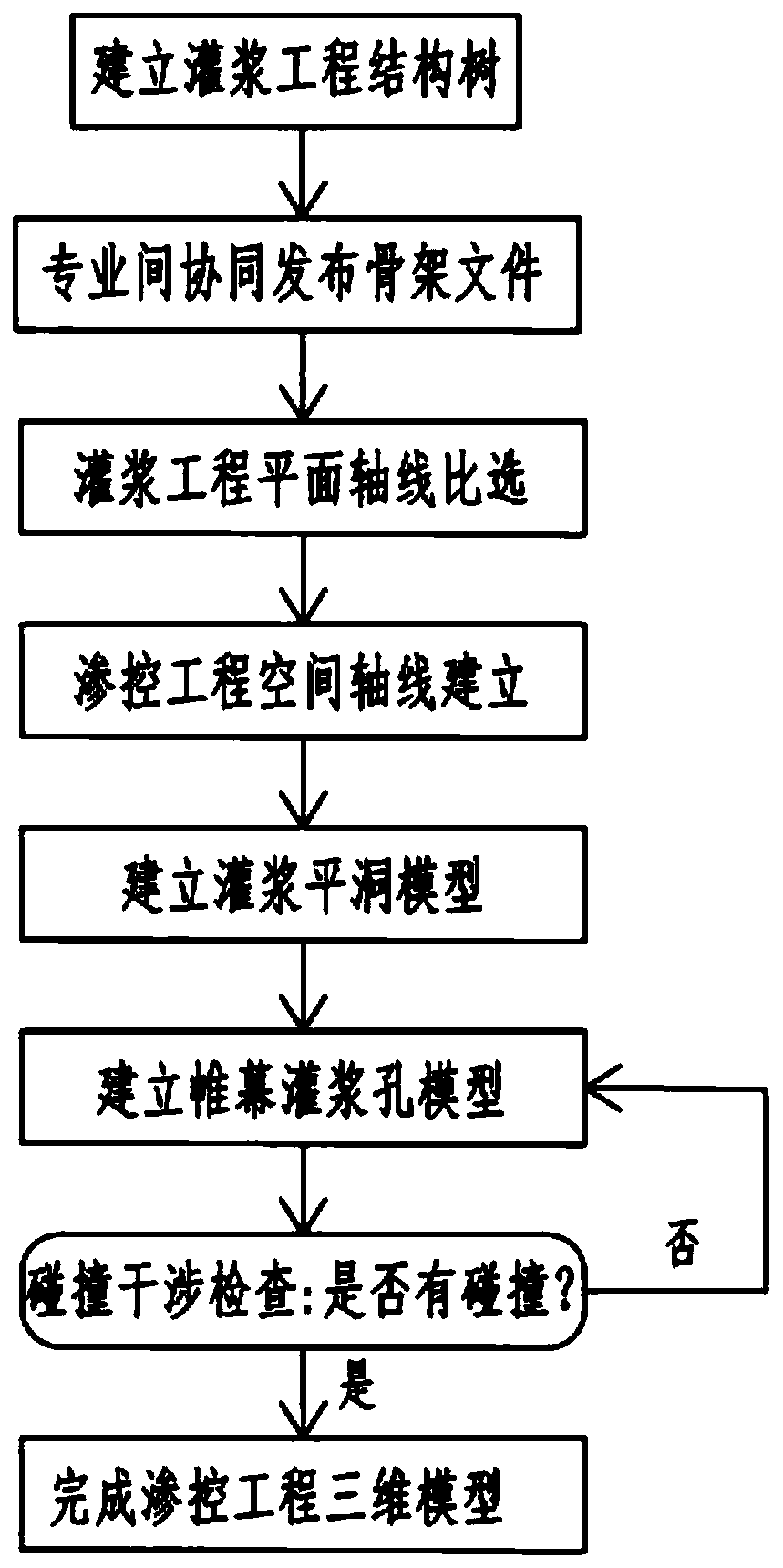

A curtain grouting and construction method technology, applied in 3D modeling, design optimization/simulation, image data processing, etc., can solve the problem of insufficient intuitive results, raw material consumption, inability to clearly and intuitively display geological bodies, grouting hole spatial position grouting Data and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] In this step, through the basic idea of "special skeleton + knowledge engineering + template", based on the user-defined template (UDF) function in 3DE, a parameterized template for grouting flat holes is established. The input elements of the template are: the ventilation shaft, the grouting flat hole of each layer, and the axis connecting the branch holes. The template input parameters are: grouting flat hole net width, net height, side wall thickness, floor thickness, top angle, drainage ditch depth, drainage ditch bottom width, and drainage ditch top width. The template calling process is as follows: a. Open the source file in the 3DE user feature calling command, and follow the prompts to select the previously established "ventilation shaft", "grouting flat hole" and "connecting branch hole axis". b. After clicking OK, a 3D model including ventilation shafts, grouting flat holes, and connecting branch holes will be generated. c. According to the needs of users, ...

Embodiment 2

[0049] According to the hydrogeological conditions, the spatial relationship between the grouting flat holes of each layer and the hub building, the arrangement of grouting holes in different parts is summarized, and the key parameter set of grouting holes (number of rows, row spacing, hole spacing, hole angle, hole depth, etc.) is determined, And based on the above parameters, a user-defined template (UDF) for grouting holes is established. The input elements of the template are: the distance between the bottom of the grouting hole (X2), the distance between the opening of the grouting hole (X1), the number of grouting holes (n), and the initial distance between the holes , The initial hole distance at the bottom of the hole. The template call process is: a. Open the source file in the 3DE user feature call command, and select the previously established "grout curtain hole axis, hole start point" and "grout curtain hole bottom axis, hole bottom start point" according to the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com