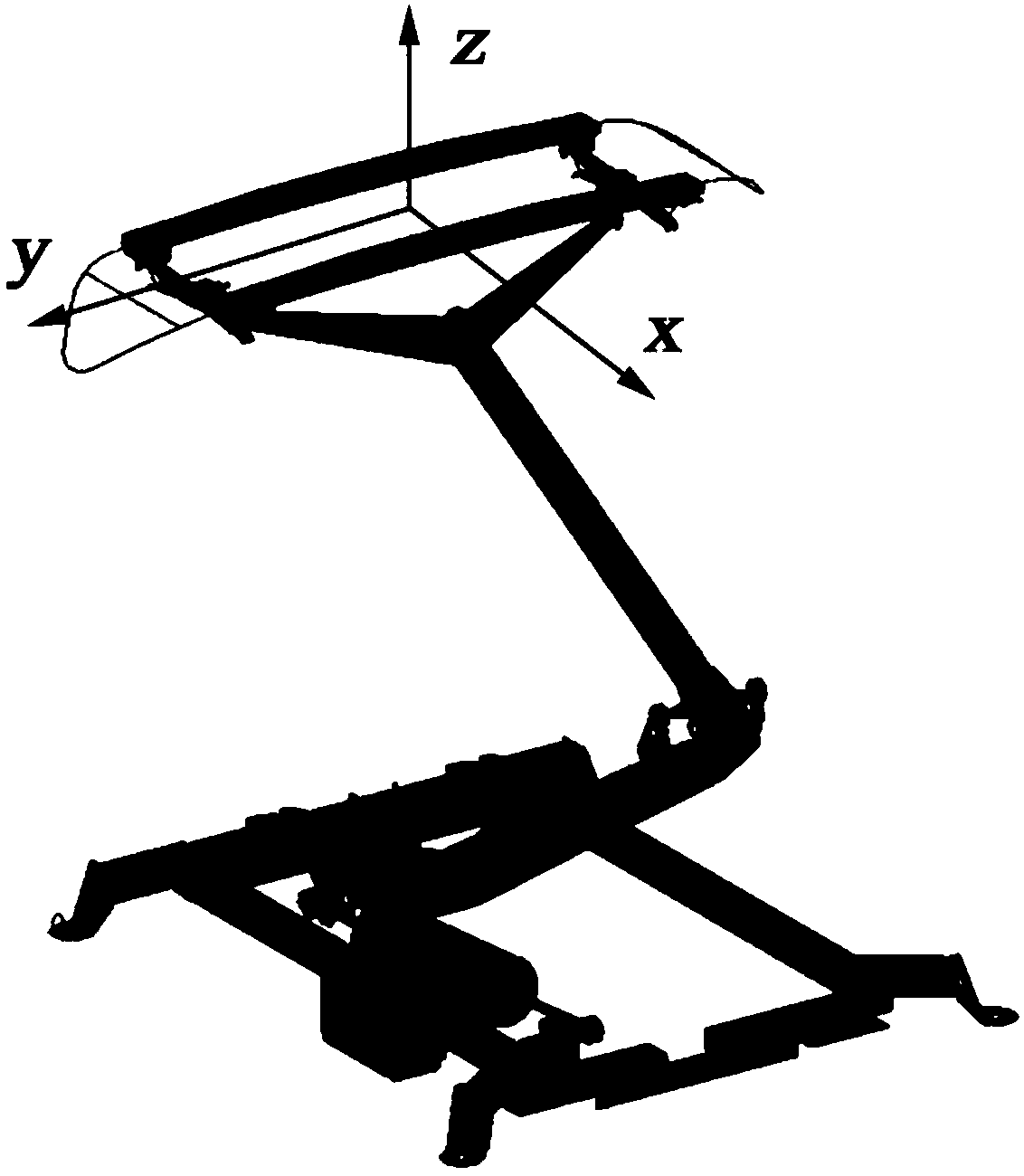

Optimization method of parallel pooling layer for optimizing surface abrasion detection model of pantograph carbon contact strip

A technology of pantograph carbon sliding plate and optimization method, applied in biological neural network model, character and pattern recognition, instruments, etc., can solve the problem of limited improvement of the effect, and achieve the effect of improving the detection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to illustrate the present invention more clearly, the present invention will be further described below in conjunction with preferred embodiments and accompanying drawings. Similar parts in the figures are denoted by the same reference numerals. Those skilled in the art should understand that the content specifically described below is illustrative rather than restrictive, and should not limit the protection scope of the present invention.

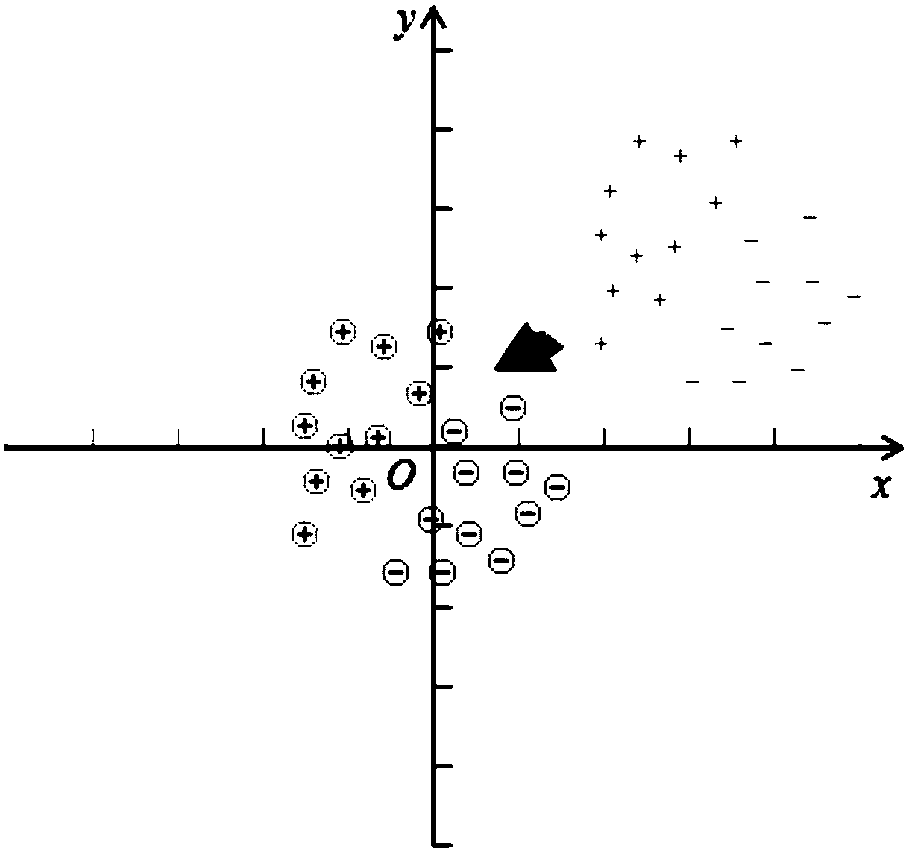

[0032] A method for optimizing the wear detection model of the surface of a pantograph carbon sliding plate with parallel pooling layers, comprising the following steps:

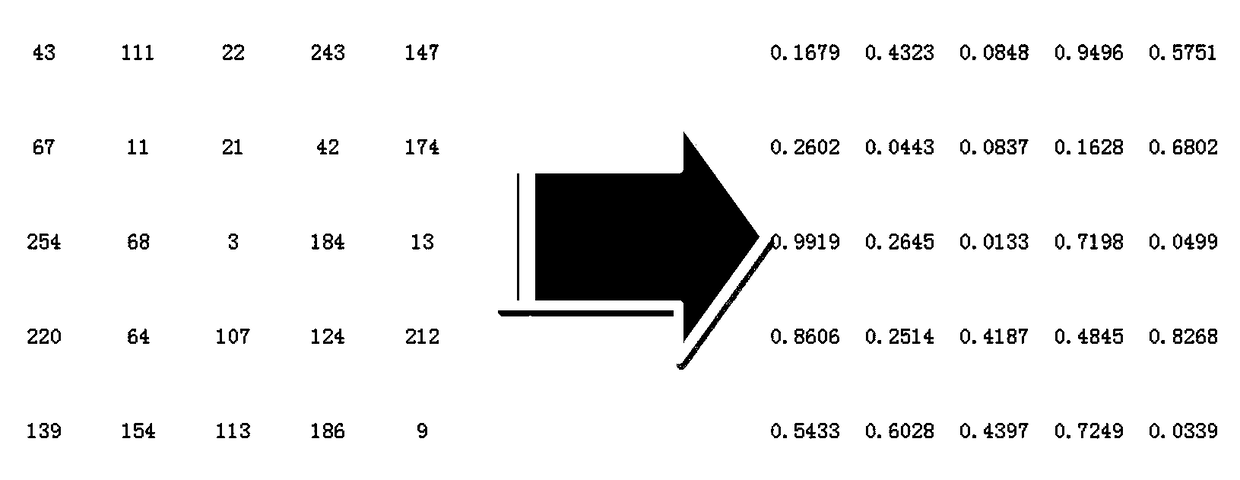

[0033] 1. Collect images of defects on the surface of the pantograph slide, and perform image preprocessing to obtain a data set; wherein, the data set includes training data and test data, and the training data includes two types: labeled data and unlabeled data;

[0034] 1) Acquisition of surface defect images of pantograph slides

[0035] The image a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com