Tire X-ray defect detection method based on twin distance comparison

A detection method and light detection technology, applied in measuring devices, image data processing, instruments, etc., can solve the problems of easy fatigue, low efficiency, and wrong judgment of the display screen, achieve high-efficiency tire X-ray defect detection, and improve detection Effect, burden reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The implementation of the present application will be described in detail below with reference to the accompanying drawings and examples, so as to fully understand and implement the implementation process of how the present application uses technical means to solve technical problems and achieve technical effects.

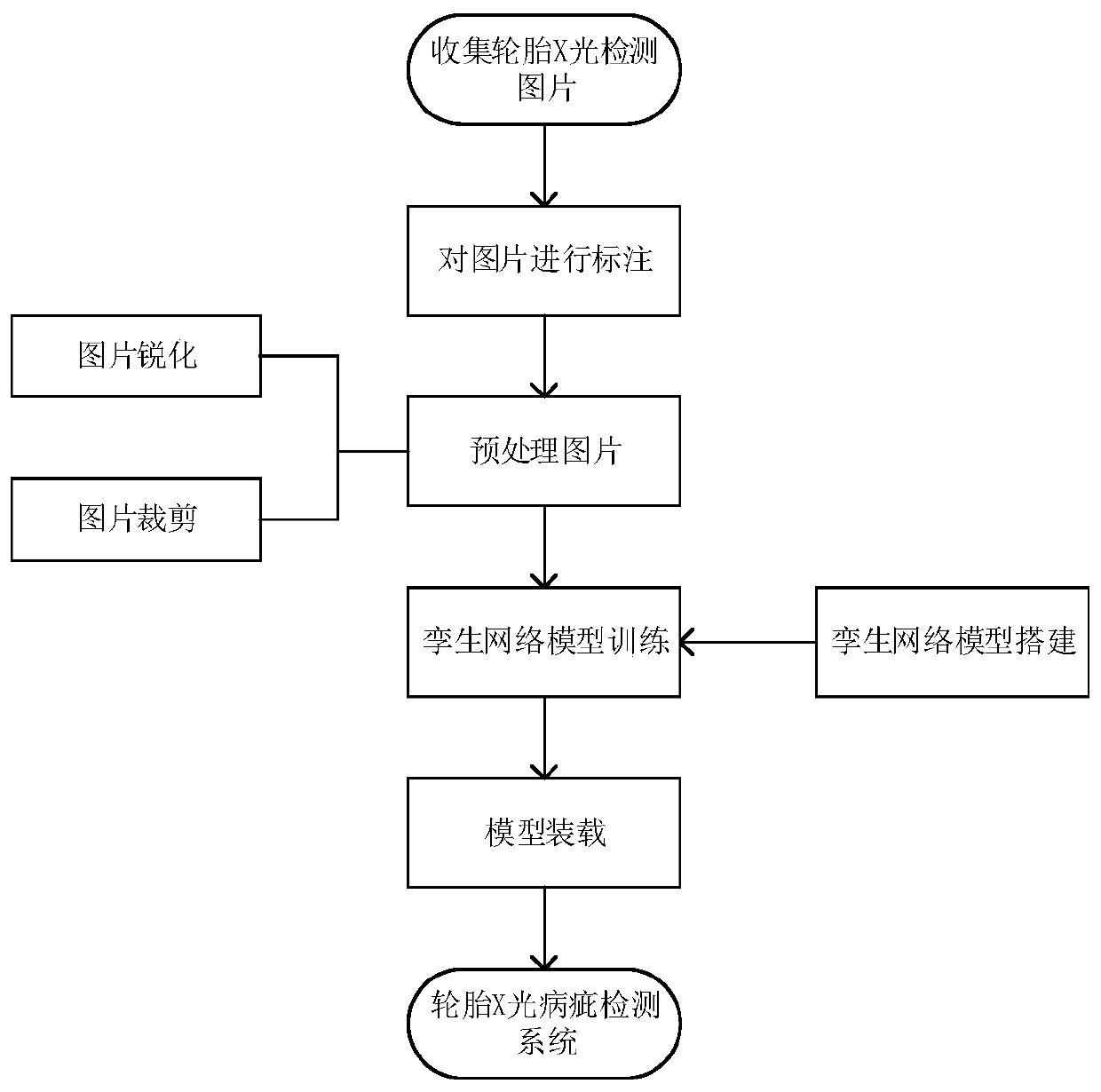

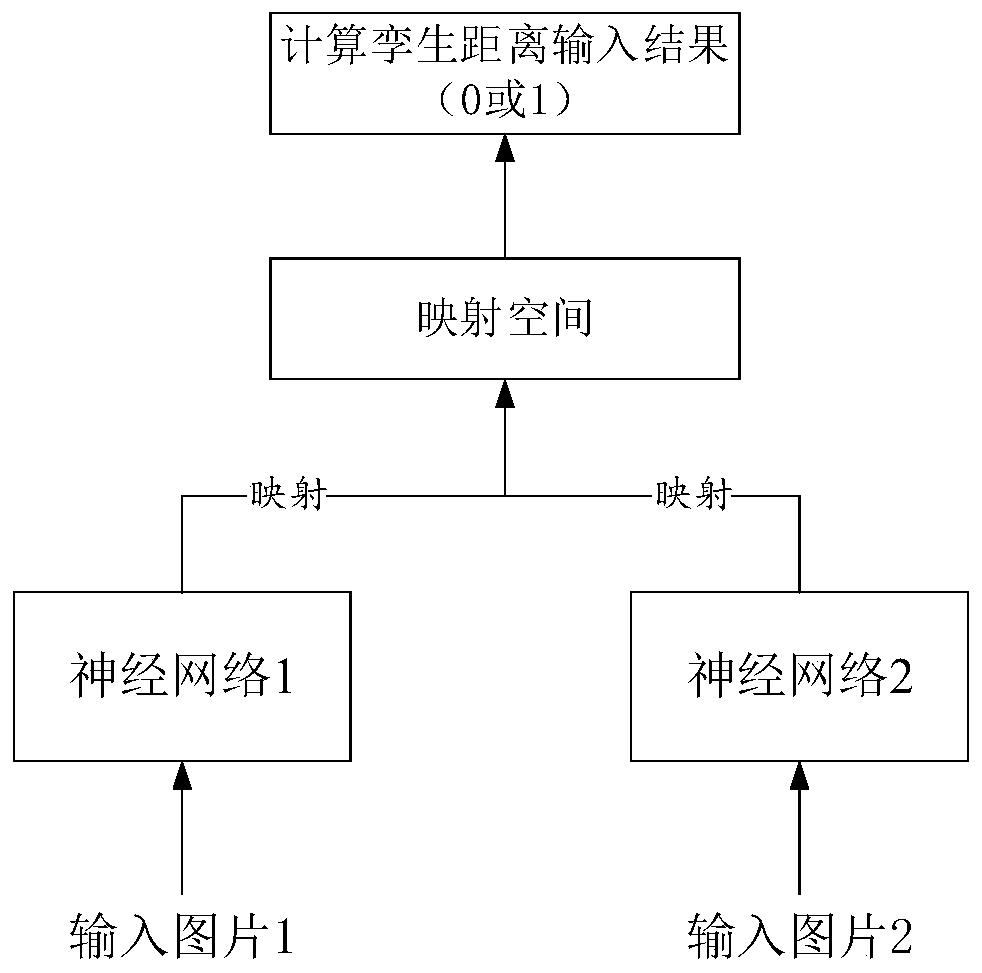

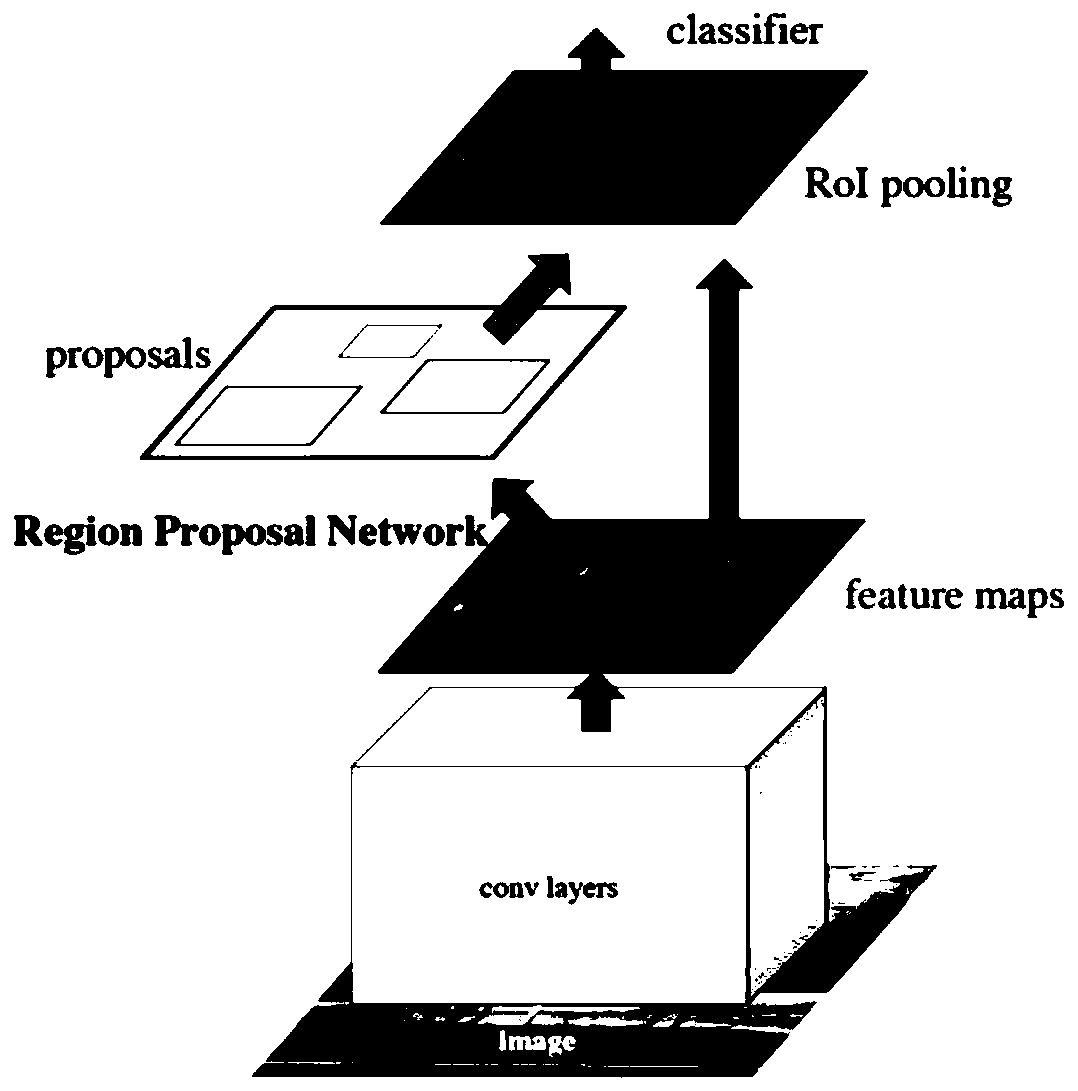

[0033] This example aims to obtain a tire X-ray defect detection method based on twin distance comparison according to this method. like figure 1 As shown, the implementation process includes the steps of collecting tire X-ray pictures, labeling pictures, preprocessing pictures, building and training twin neural network models, and loading models. The specific implementation process is as follows:

[0034] (1) Collect tire X-ray image data as a sample set. The collected pictures are pictures with the same size (assumed to be 20000×1900 in the example) and similar clarity taken by an X-ray machine with similar shooting effects, and the tread patterns of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com