Manual oblique nozzle fillet weld phased array scanning device capable of performing bidirectional scanning

A technology for scanning devices and mitered tubes, which is applied to measuring devices, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, and using sound waves/ultrasonic waves/infrasonic waves for material analysis, etc., which can solve the problems that cannot be applied, cannot be implemented, and cannot meet the detection requirements and other issues, to achieve the effect of enhancing the technical effect and facilitating the use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

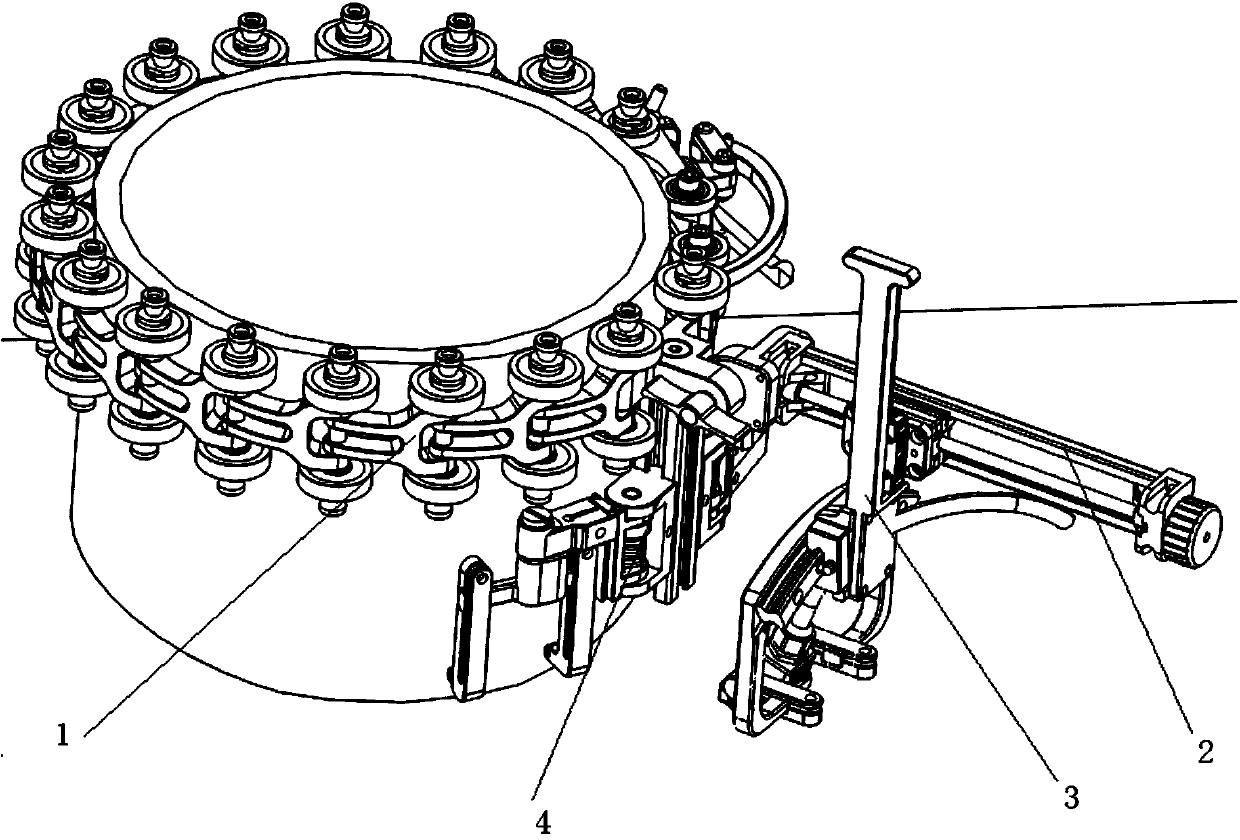

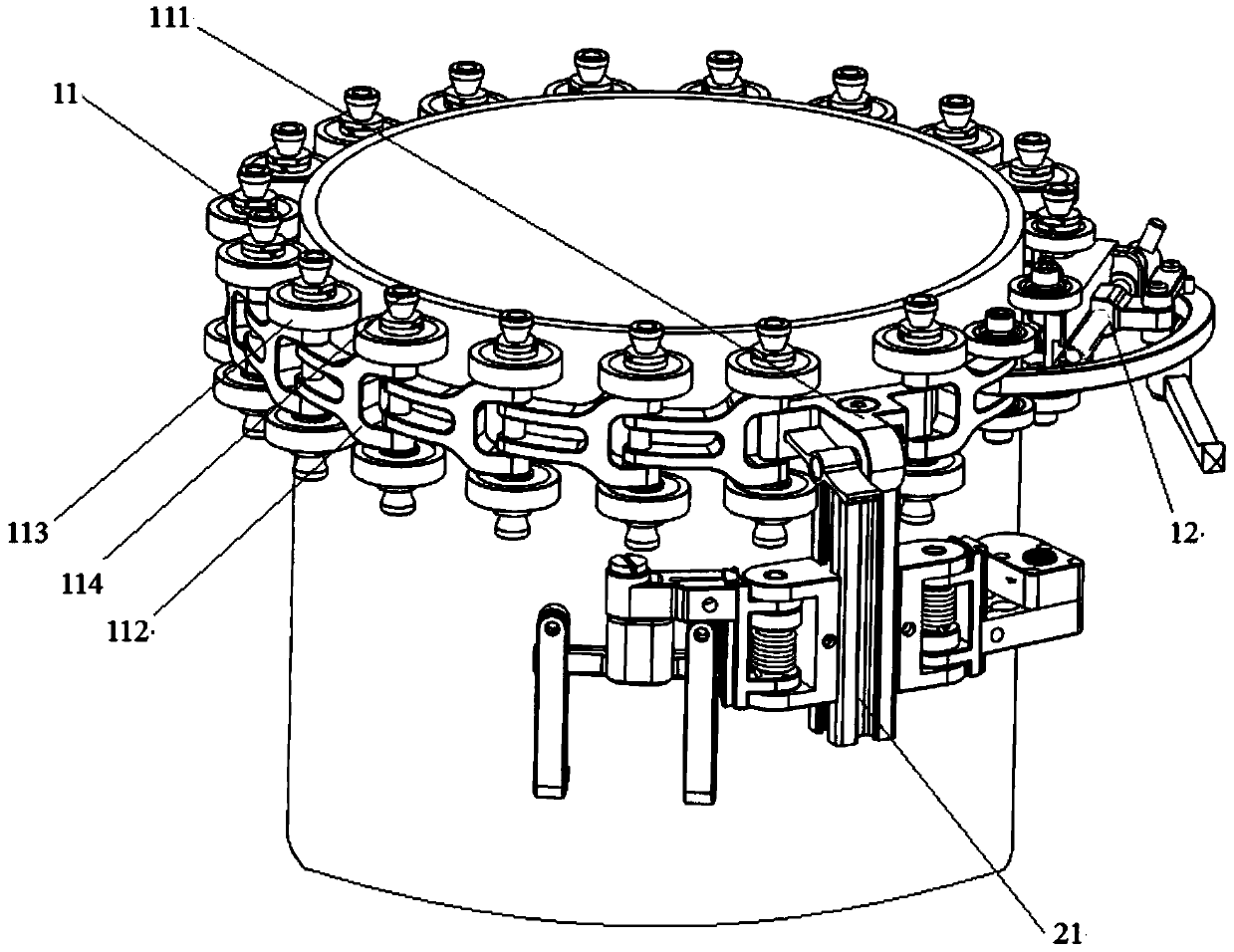

[0045] Such as Figure 1-10 As shown in the patent, a manual phased array scanning device for miter pipe fillet welds that can scan bidirectionally includes a locking mechanism 1 , an adjusting mechanism 2 , a probe frame slide bar assembly 3 and a pipe probe arm 4 .

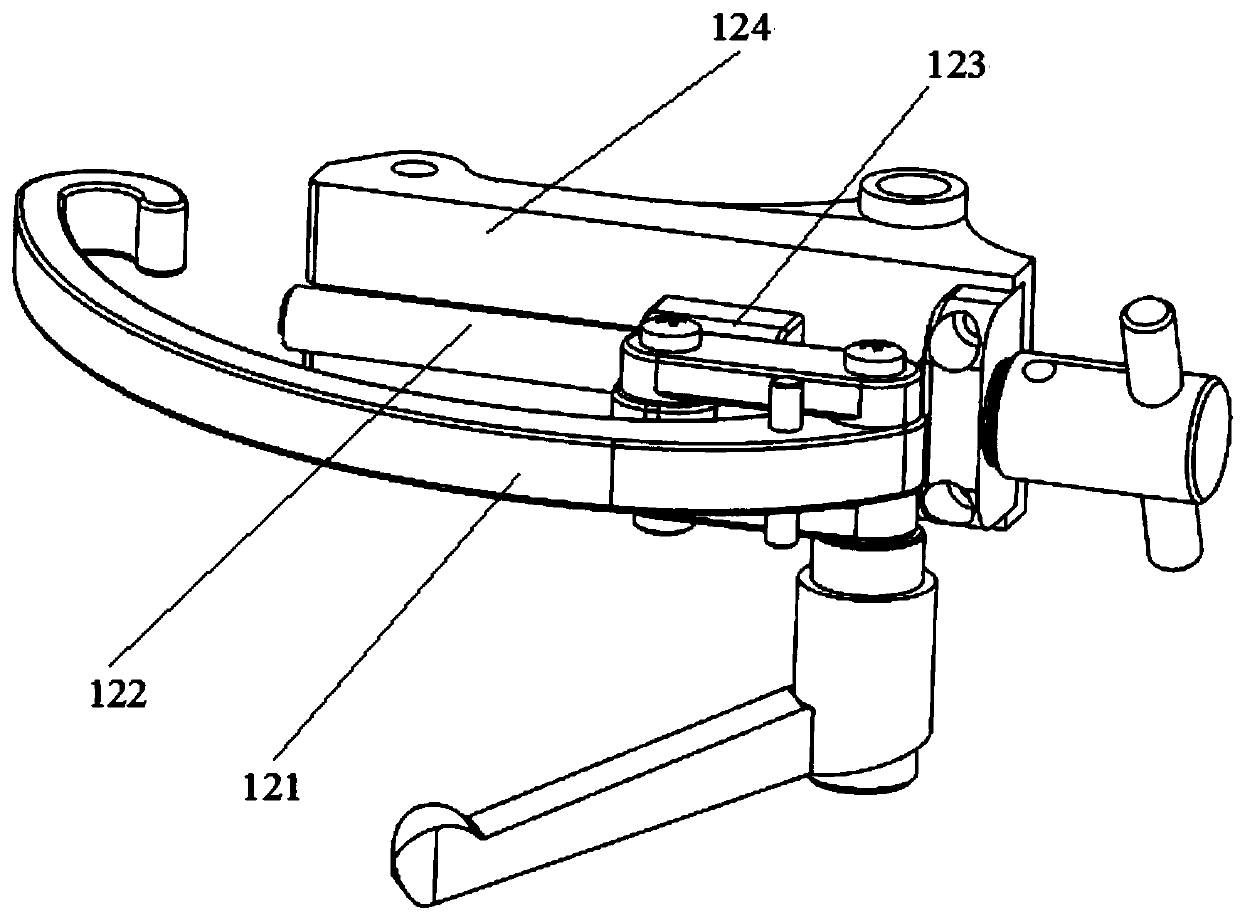

[0046] The locking mechanism 1 includes a chain link assembly 11 and a locking assembly 12. The chain link assembly 11 includes a connecting head 111, a short chain link 112, a chain link pin, a roller 113 and a fixed head 114; The mounting hole for connecting the rod assembly 3, the middle part is provided with a fixing hole connected with the upper end of the profile rod 21 of the automatic adjustment mechanism 2, and the two ends of the connecting head 111 are provided with connecting through holes connected with the short chain link 112; the connecting head 111 and the short chain The joints 112 are all connected by chain link pins to form a chain structure, and the rollers 113 are respectively arranged at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com