Forming mechanism of round sheath wire stripping head terminal riveting and heat-shrink tube lining machine

A molding mechanism and sheathed wire technology, applied in the direction of line/collector parts, electrical components, circuits, etc., can solve the problems of high production cost, low production efficiency, complicated manufacturing process, etc., to promote the development of productivity and save a lot cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

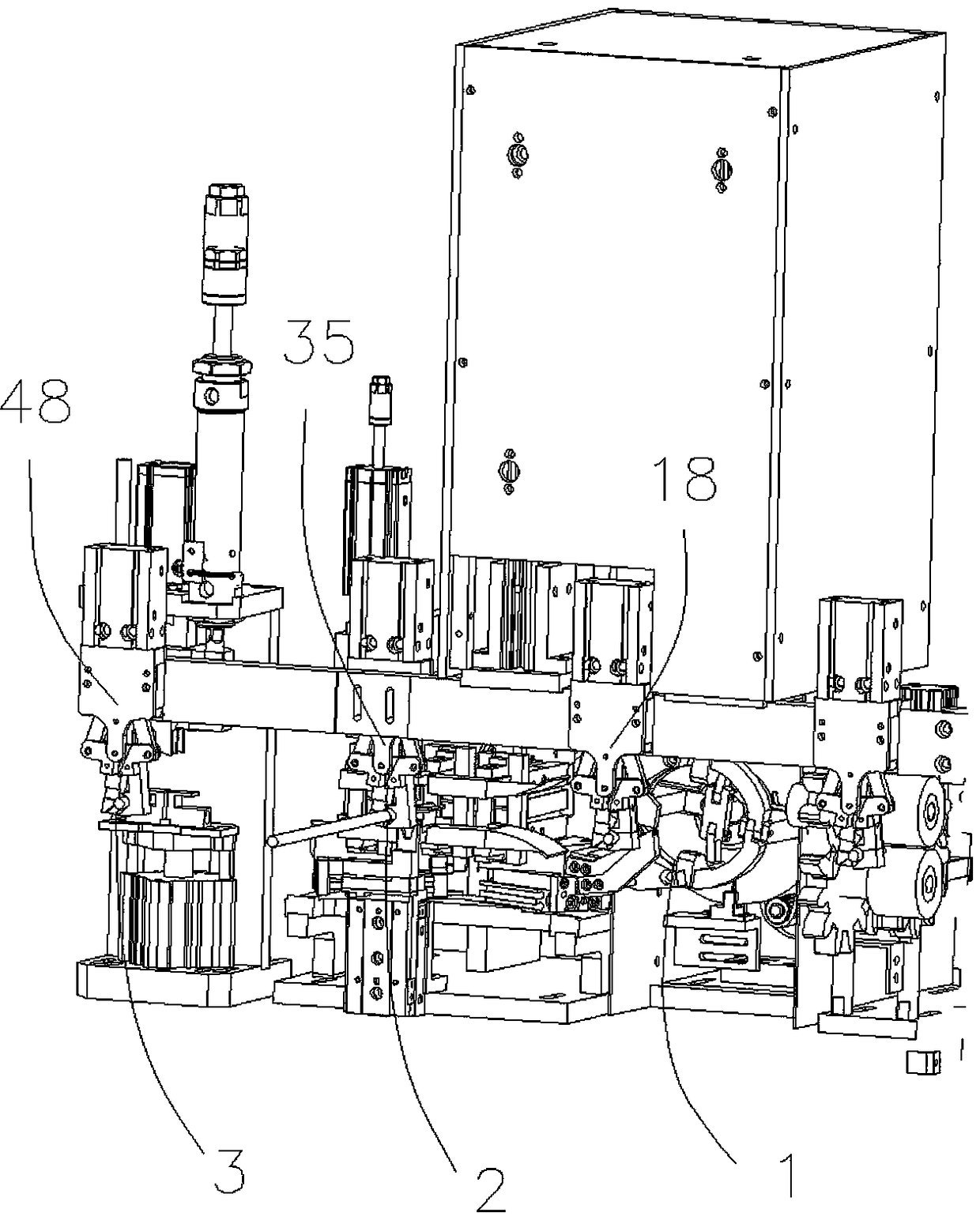

[0023] combined with Figures 1 to 5 , a forming mechanism of a round sheath wire stripping head and end piercing heat-shrinkable tube machine, including a shaping station 1, a splitting station 2, and a secondary splitting station 3;

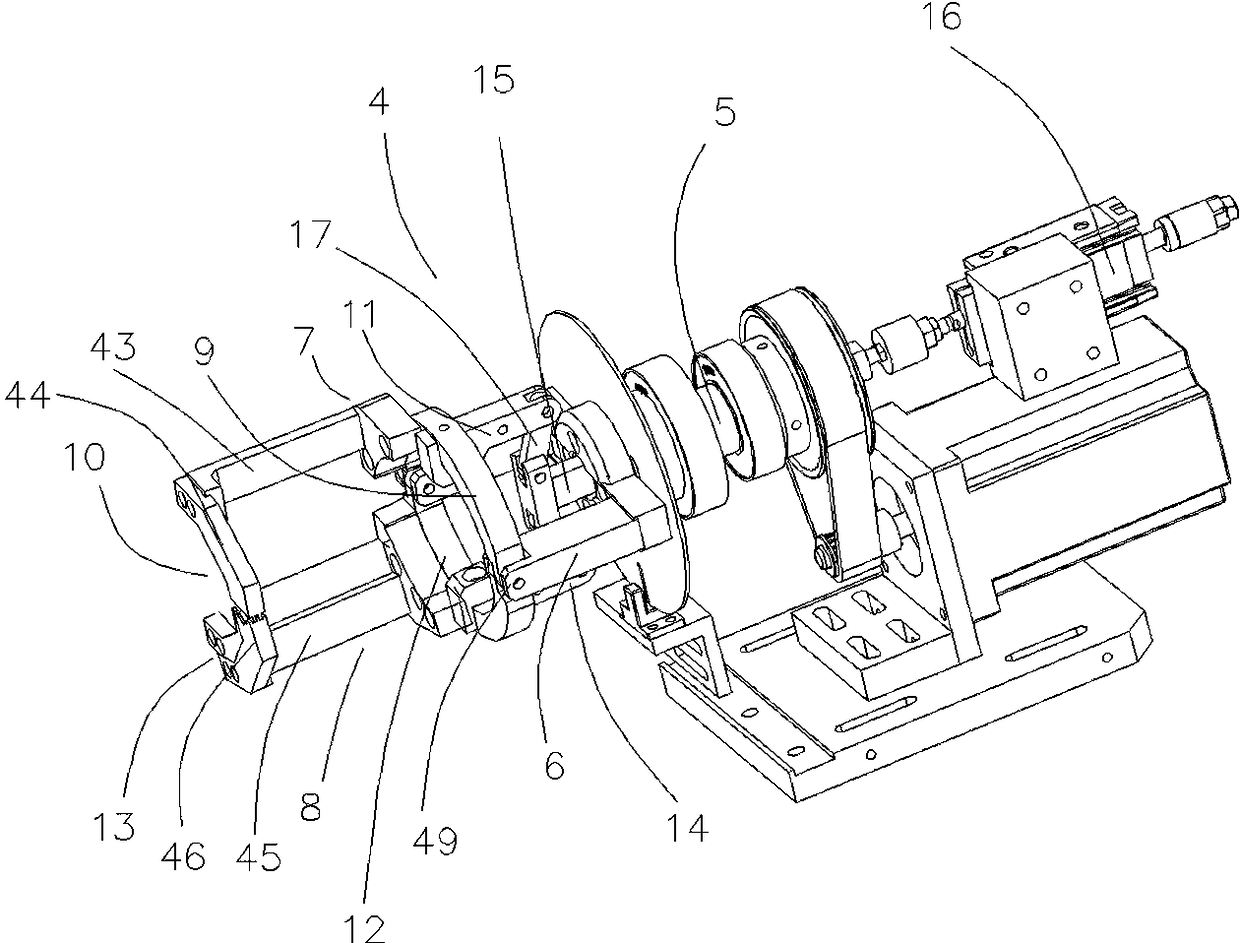

[0024] combined with figure 2 , the shaping station 1 includes a rotary clamping claw 4, the rotary clamping claw 4 includes a rotating shaft 5, the rotating shaft 5 is driven by a servo motor belt, and the front end of the rotating shaft 5 protrudes two A base arm 6 with a hinged ear 20, on which an upper clip 7 and a lower clip 8 are hinged, and the upper clip 7 includes a first rotating body 9 and an upper jaw positioned at the front of the first rotating body 9 10. There is a first driving handle 11 behind the first rotating body 9, and the two ends of the first rotating body 9 are hinged on the hinge ears 20; the lower clamp 8 includes a second rotating body 12 and is located on the second rotating body 12 The lower jaw 13 in the front,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com