Centrifugal high-rise escape device and working method thereof

An escape device and centrifugal technology, applied in life-saving equipment, building rescue and other directions, can solve the problems of hydraulic damping system leakage, difficult to achieve uniform descent, difficult to control the size of frictional resistance, etc., to ensure the effect of human safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

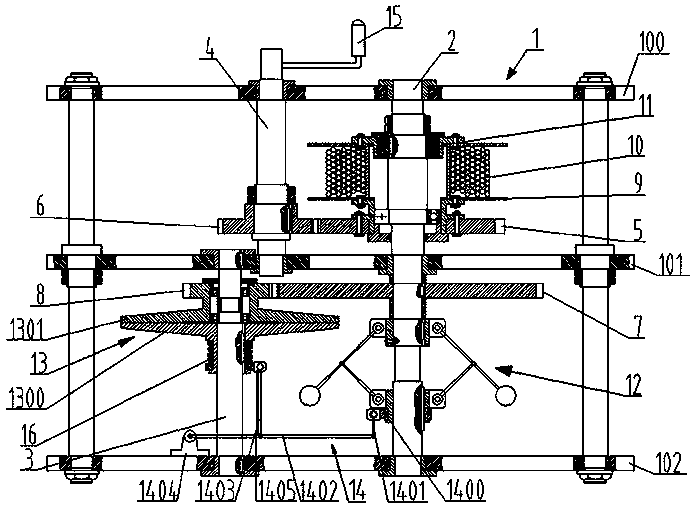

[0051] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

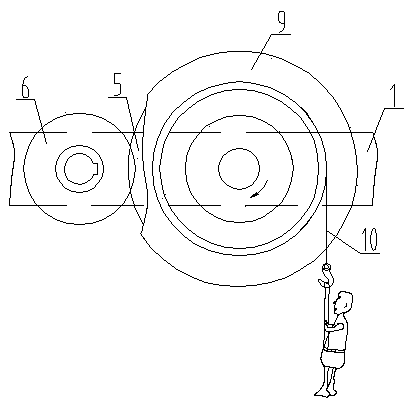

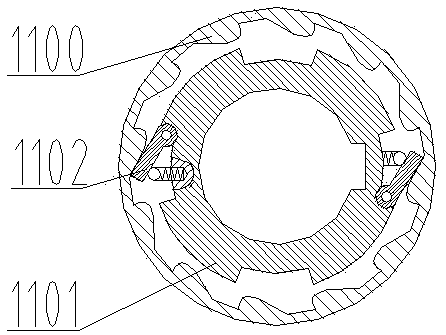

[0052] Such as figure 1 As shown, a centrifugal high-rise escape device includes a bracket 1, a shaft 2, a shaft 2 3, a shaft 3 4, a gear 5, a gear 2 6, a gear 3 7, a gear 4 8, a reel 9, a wire rope 10, Ratchet mechanism 11, centrifugal speed regulating mechanism 12, friction disc mechanism 13 and lever drive mechanism 14, wherein,

[0053] The two ends of the first axis 2, the second axis 3 and the third axis 4 are respectively supported and positioned on the bracket 1, and the first axis 2, the second axis 3 and the third axis 4 are arranged in parallel, and the third axis 4 is arranged in the radial direction The top is located between axis one 2 and axis two 3 .

[0054] In the present embodiment, the support 1 includes a support plate 100, a suppo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com