Trailer and suspension system thereof

A suspension system and vehicle frame technology, applied in the field of transportation, can solve the problems of limited space for steering mechanism and the inability of steering axles to be installed together, and achieve the effect of reducing tire wear and being easy to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

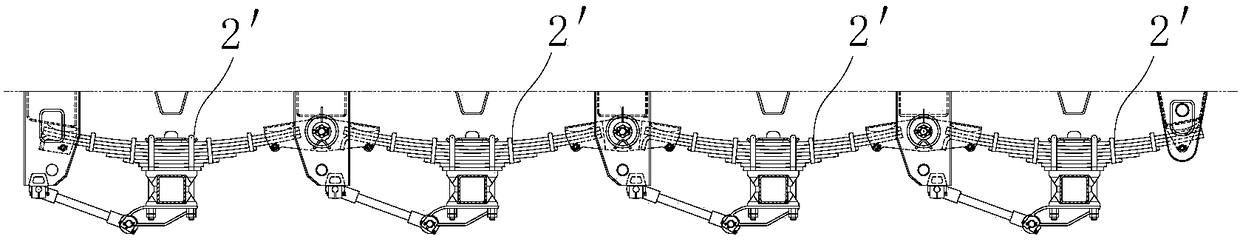

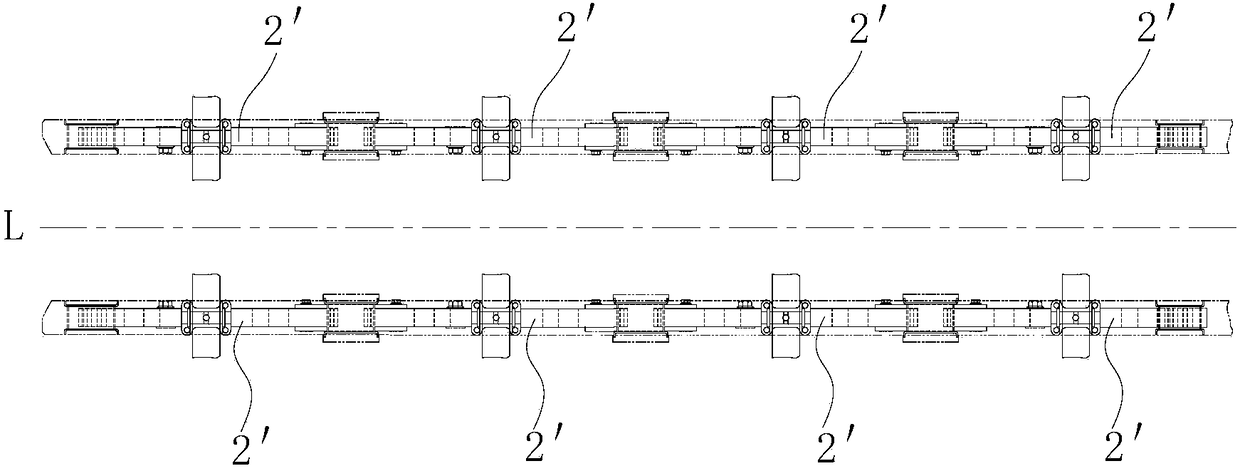

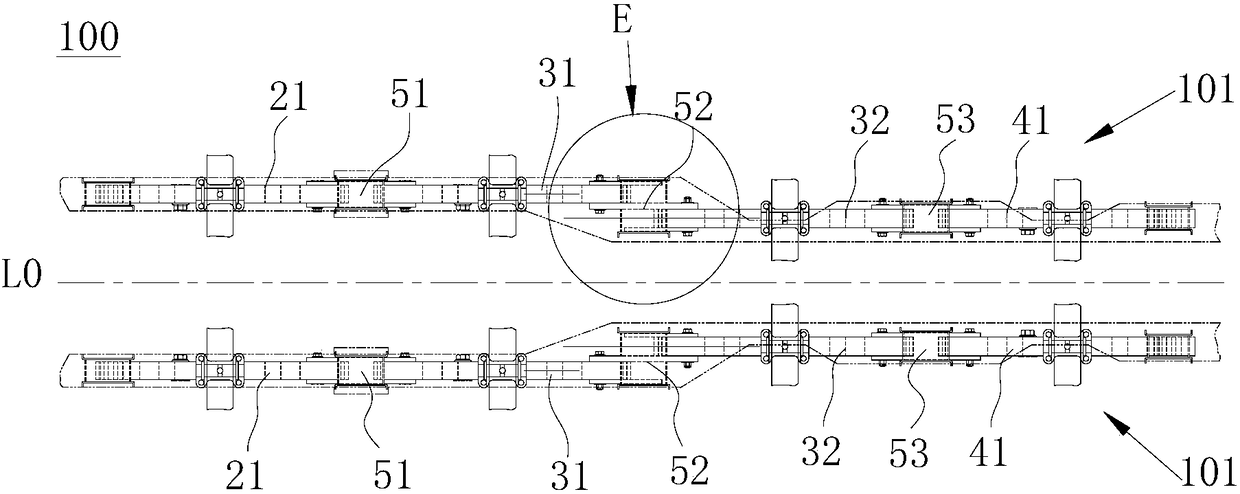

[0031] Such as image 3 and Figure 5 As shown, the suspension system 100 of the trailer in this embodiment is a four-axle suspension.

[0032] The suspension system 100 includes: two symmetrically arranged sub-suspension systems 101, each sub-suspension system 101 includes a plurality of leaf springs sequentially connected along the length direction of the vehicle body, and the width of each leaf spring is 90mm. According to the front and rear arrangement of the vehicle body, they are respectively: the front leaf spring 21 , the first middle leaf spring 31 , the second middle leaf spring 32 and the rear leaf spring 41 . Wherein, the center distance of the rear leaf spring 41 of the suspension system 100 is smaller than the center distance of the front leaf spring 21, and the center distance of the first middle leaf spring 31 is the same as the center distance of the front leaf spring 21, and the center distance of the second middle leaf spring 32 The center-to-center distan...

Embodiment 2

[0049] Such as Figure 8 and Figure 9 As shown, the structure of the suspension system 100 of the trailer in this embodiment is roughly the same as that in Embodiment 1, except that the suspension system 100 of the trailer in this embodiment is a five-axis suspension.

[0050] That is to say, in this embodiment, the middle leaf spring further includes a third middle leaf spring 33 . The third middle leaf spring 33 is connected to the second middle leaf spring 32 and the rear leaf spring 41 respectively. Correspondingly, the third middle leaf spring 33 and the rear leaf spring 41 are connected to each other by adding a fourth balance arm 54 , and the fourth balance arm 54 is connected to the longitudinal beam 11 of the trailer through the fourth middle spring bracket 65 . The connecting structure of the third middle leaf spring 33, the second middle leaf spring 32 and the rear leaf spring 41 is the same as that of the front leaf spring 21 and the first middle leaf spring 31,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com