A power-assisted device for a human-driven vehicle

A technology of human-driven and power-assisted devices, which is applied in the directions of rider drive, vehicle components, transportation and packaging, etc., can solve the problems of high cost, large autonomous riding resistance, and inconvenient combination and separation of motors and wheels, and achieves cost-effective solutions. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

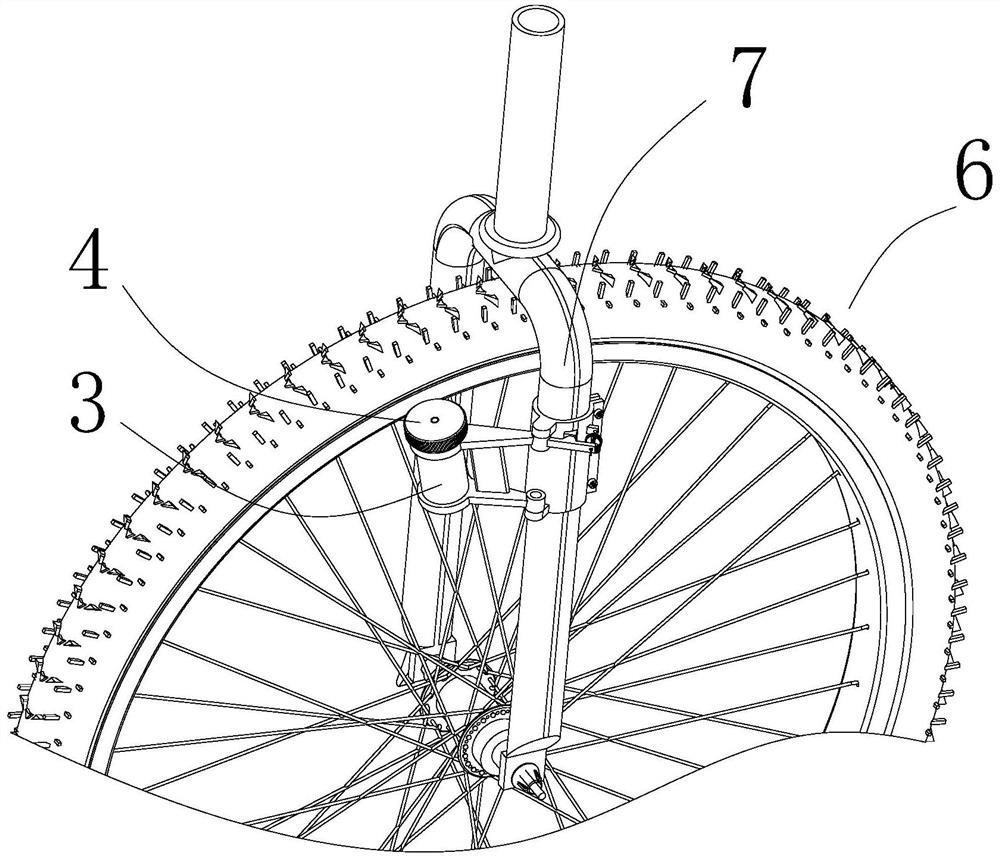

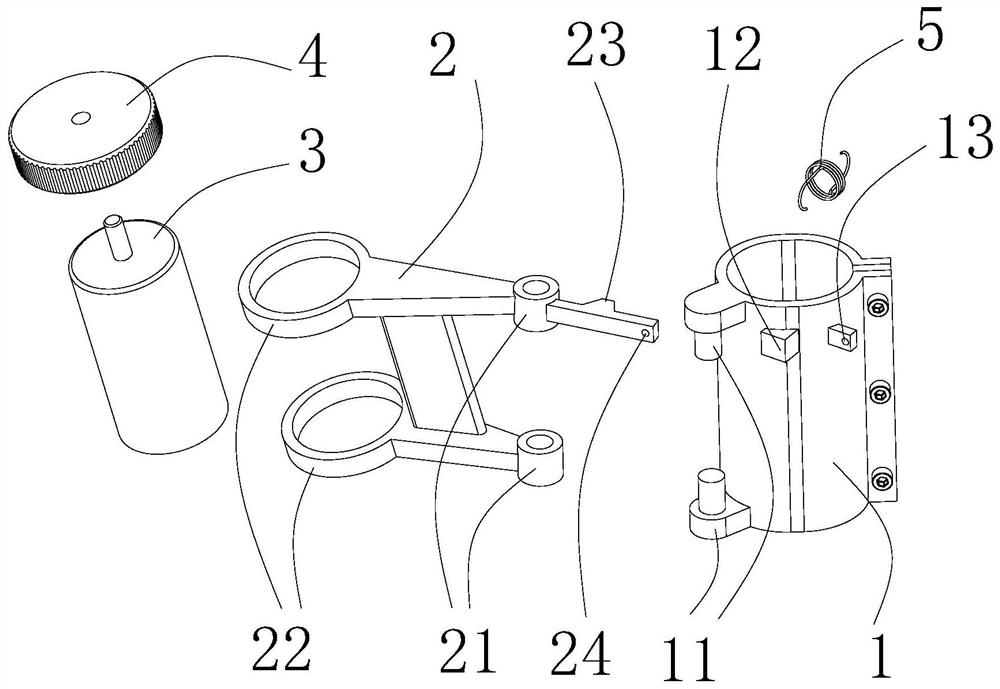

[0044] like figure 1 and figure 2 As shown, the first bracket 1 is fixedly connected to the vehicle frame 7, the first end 21 of the second bracket 2 is swingingly connected to the first bracket 1, and the second end 22 of the second bracket 2 is fixedly connected to the power assembly 3. The driving wheel 4 is driven to rotate in three parts. When the power is boosted, the driving wheel 4 is in contact with the side of the wheel assembly 6, and the wheel assembly 6 is driven to rotate by the friction force. The component of this friction force presses the driving wheel 4 and the side of the wheel assembly 6 .

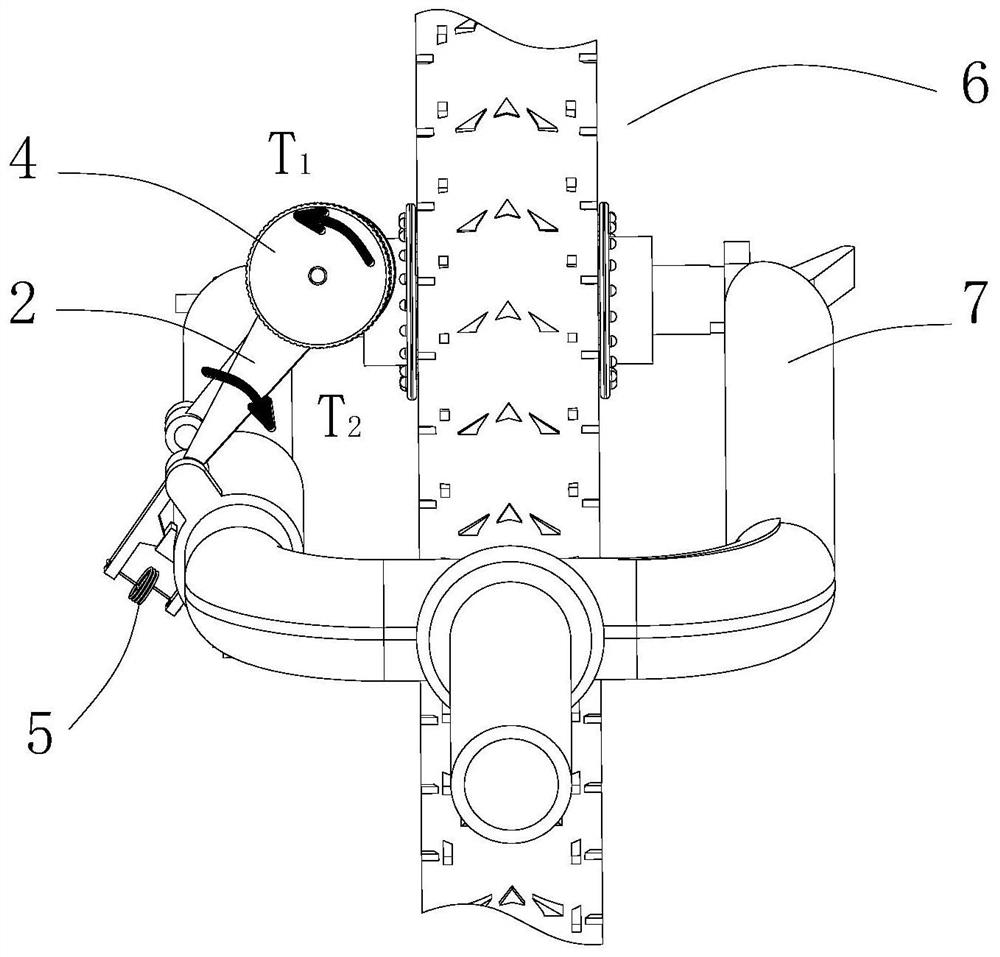

[0045] like image 3 As shown, when the power is not assisted, that is, when the power assembly 3 does not receive an assist command, the power assembly 3 does not rotate, and the driving wheel 4 and the wheel assembly 6 are not in contact. When assisting, when the powertrain 3 starts to rotate after receiving the assist command, a driving torque T is applied to th...

Embodiment 2

[0053] Above-mentioned embodiment only is provided with booster device on one side of wheel assembly 6, as Figure 4 As shown, the force F of the driving wheel 4 pressing on the wheel assembly 6 2 It can only be resisted by the structural strength of the wheel assembly 6, in order to better balance this force, such as Image 6 and Figure 7 As shown, the booster device shown in Embodiment 1 is set as a mirror image with respect to the equatorial plane of the wheel assembly 6 to form Embodiment 2, that is, two sets of booster devices in Embodiment 1 are symmetrical about the equatorial plane of the wheel assembly 6 The arrangement constitutes the second embodiment, and the geometric principle remains unchanged. It also increases the redundancy of the system and improves the reliability.

[0054] The output shafts of the powertrains 3 on both sides will simultaneously rotate in the set direction and rotate at the speed required by the instruction when receiving the power assi...

Embodiment 3

[0056] like Figure 8 to Figure 11 As shown, on the basis of the first embodiment above, the power booster is rotated as a whole by 90° so that the driving wheel 4 is in contact with the inner peripheral surface of the wheel rim of the wheel assembly 6. When in contact, the rotation axis of the driving wheel 4 is in contact with the wheel assembly 6 The axes are parallel to obtain embodiment three, the radial force produced during driving is borne by the wheel assembly 6, the wheel assembly 6 has high radial strength, and the radial force will not have a negative impact on the structure of the wheel assembly 6.

[0057] like Figure 8 and Figure 9 As shown, the first bracket 1 is fixedly connected to the vehicle frame 7, the first end 21 of the second bracket 2 is connected to the first bracket 1 in a swinging manner, the second end 22 of the second bracket 2 is fixedly connected to the powertrain 3, and the powertrain 3 drives the driving wheel 4 to rotate, and when power ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com