Preparation method of red koji distillers' grain arrack

A technology of red koji grains and red koji wine, applied in the preparation of alcoholic beverages, etc., can solve problems such as low sales and prices, small consumer market, and slow development of shochu liquor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

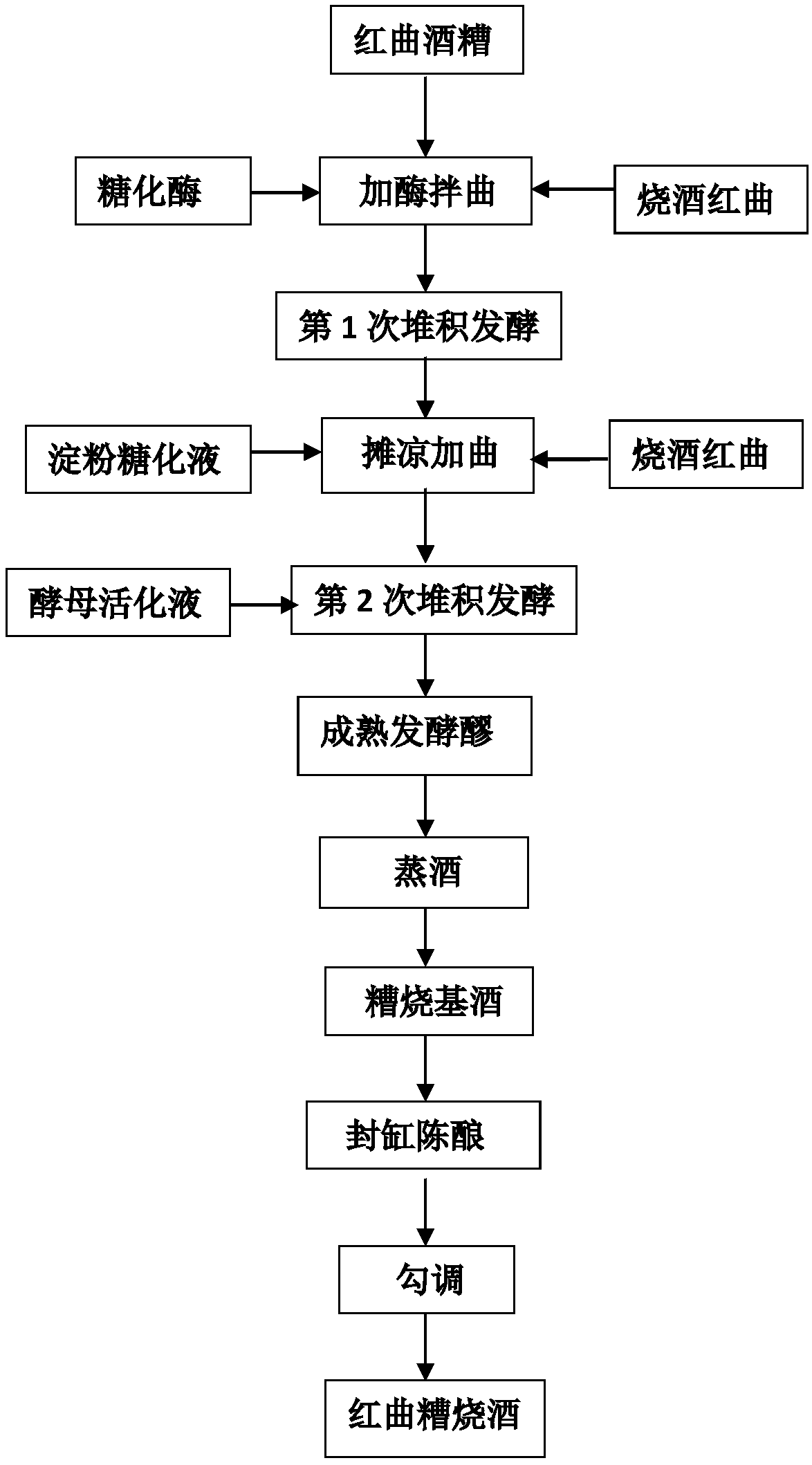

Method used

Image

Examples

Embodiment 1

[0040] 1. Raw material formula by weight:

[0041] Red yeast distiller's grains 100kg

[0042] Barley Bran 10kg

[0043] Shochu red yeast rice 6 kg

[0044] Glucoamylase 0.02kg

[0045] Yeast activation solution 5kg

[0046] Starch saccharification solution 10kg

[0047] 2. Preparation method:

[0048] 1. The first accumulation fermentation:

[0049] (1) Crushing of distiller's grains: add 5 kg of barley bran to 100 kg of red yeast rice distiller's grains according to the raw material formula, mix well, and use a grinder to crush into loose and fine-grained red yeast rice distiller's grains.

[0050] (2) Stacking fermentation: add 0.02kg of glucoamylase and 6kg of shochu red yeast rice to the crushed fine-grained red yeast rice distiller's grains, mix and pile up, compact slightly, cover the bad surface with a plastic film for stacking fermentation, and control the temperature during the fermentation process At 36-38°C, after 6 days of fermentation, the first accumulati...

Embodiment 2

[0057] 1. Raw material formula by weight:

[0058] Red yeast distiller's grains 100kg

[0059] Barley Bran 10kg

[0060] Shochu red yeast rice 12 kg

[0061] Glucoamylase 0.02kg

[0062] Yeast activation solution 3kg

[0063] Starch saccharification solution 15kg

[0064] 2. Preparation method:

[0065] 1. The first accumulation fermentation:

[0066] (1) Crushing of distiller's grains: add 5 kg of barley bran to 100 kg of red yeast rice distiller's grains according to the raw material formula, mix well, and use a grinder to crush into loose and fine-grained red yeast rice distiller's grains.

[0067](2) Stacking fermentation: add 0.02kg of glucoamylase and 6kg of shochu red yeast rice to the crushed fine-grained red yeast rice distiller's grains, mix and pile up, compact slightly, cover the bad surface with a plastic film for stacking fermentation, and control the temperature during the fermentation process At 36-38°C, after 6 days of fermentation, the first accumulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com