Adjustable turbocharger system

A turbocharger and supercharger technology, applied in the field of machinery, can solve the problems of reducing the supercharging effect and failing to meet the energy saving and emission reduction targets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

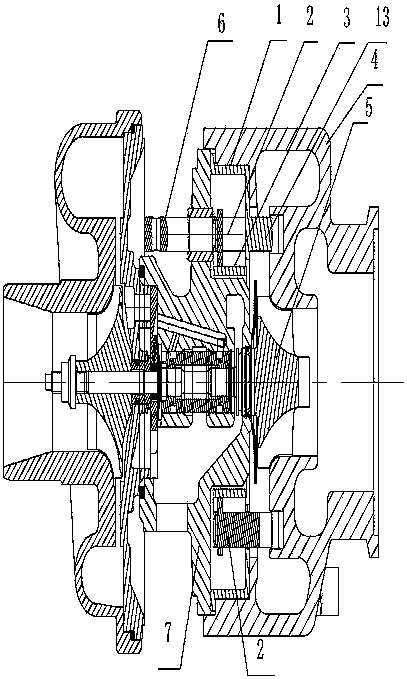

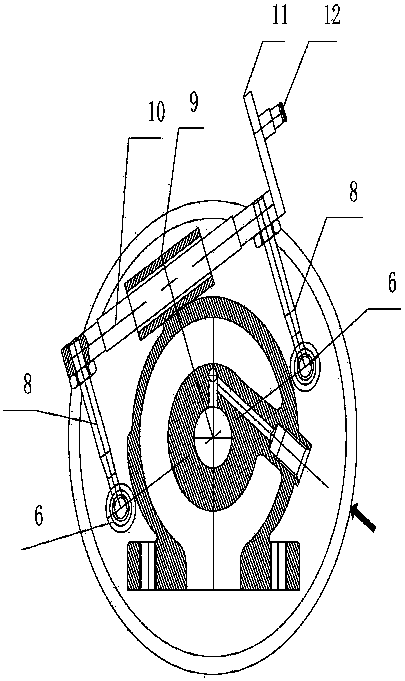

[0026] Such as figure 1 As shown, the supercharger includes a turbine housing 4, an intermediate housing 7 with a raised portion in the middle, a turbine 5, and a turbine drive shaft. The exhaust gas turbine components are installed in the intermediate housing and fixed to the turbine housing. The turbine housing has a built-in turbine. The transmission shaft, the raised part of the intermediate shell is arranged at the root and bottom of the turbine, and the turbine is in the volute cavity. It is characterized in that the supercharger also includes a cap-shaped fixed vane nozzle ring 1 with a hole in the middle, a plurality of adjustable Vane nozzle 2, adjustable cylindrical nozzle 3 and two T-shaped levers 6, fixed nozzles 13 are evenly distributed on the side end surface of the fixed vane nozzle ring, and the fixed nozzles are arranged in the exhaust flow channel of the volute cavity and flow in the direction of the exhaust gas flow. With a certain inclination angle, the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com