Method and device for detecting surface shape of planar component through adopting slope splicing

A technology for detecting plane and slope, which can be used in measurement devices, optical devices, graphics and image conversion, etc., and can solve problems such as incomplete correction of slope errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the purpose and solution of the present invention more clear, the implementation manner of the present invention will be further described below in conjunction with the accompanying drawings. It is necessary to point out that the following examples are only used for further description of the present invention, and cannot be interpreted as limiting the protection scope of the present invention, and those skilled in the art make some non-essential improvements to the present invention according to the above-mentioned content of the present invention And adjustments still belong to the protection scope of the present invention.

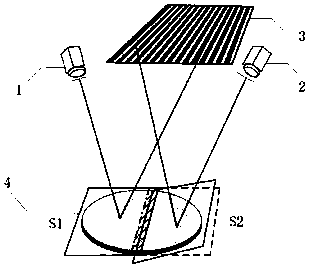

[0025] Please refer to figure 1 , the embodiment of the present invention provides a method and device for detecting the surface shape of a planar element by slope splicing. Its basic components include No. 1 pinhole camera 1, No. 2 pinhole camera 2, display 3 and DUT 4. It should be noted that the number of pinhole cameras is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com