Design method for back pressure-bearing flat cover

A design method and flat cover technology, applied in computer-aided design, calculation, special data processing applications, etc., can solve the problems of no given, no positive pressure flat cover for maintenance, insufficient structural strength of back pressure flat cover, etc. Maintenance cost and effect of controlling installation and maintenance cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

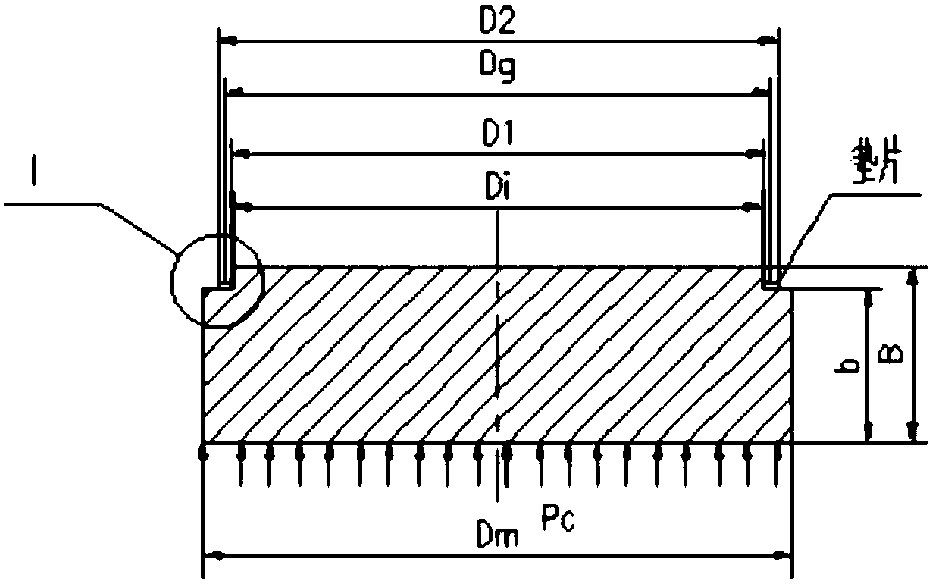

[0076] Specific implementation mode 1: A method for designing a flat cover with back pressure in this embodiment, the size parameters of the flat cover under back pressure are: the total thickness of the flat cover B, the thickness of the stepped section b, the back pressure is P, and the calculated pressure is Pc , the diameter of the force center circle of the gasket is Dg, the outer diameter of the gasket contact circle is D2, the inner diameter of the gasket contact circle is D1, the diameter of the dangerous section of the step is Da, and the radius of the transition circle at the corner of the step is R.

[0077] A method for designing a back pressure-bearing flat cover, comprising the following steps:

[0078] Step 1: Calculate the diameter Dg of the center circle of the gasket pressing force;

[0079] Step 2: Calculate the total thickness B value of the flat cover;

[0080] Step 3: Calculate the total force W on the back of the flat cover due to the calculated pressur...

specific Embodiment approach 2

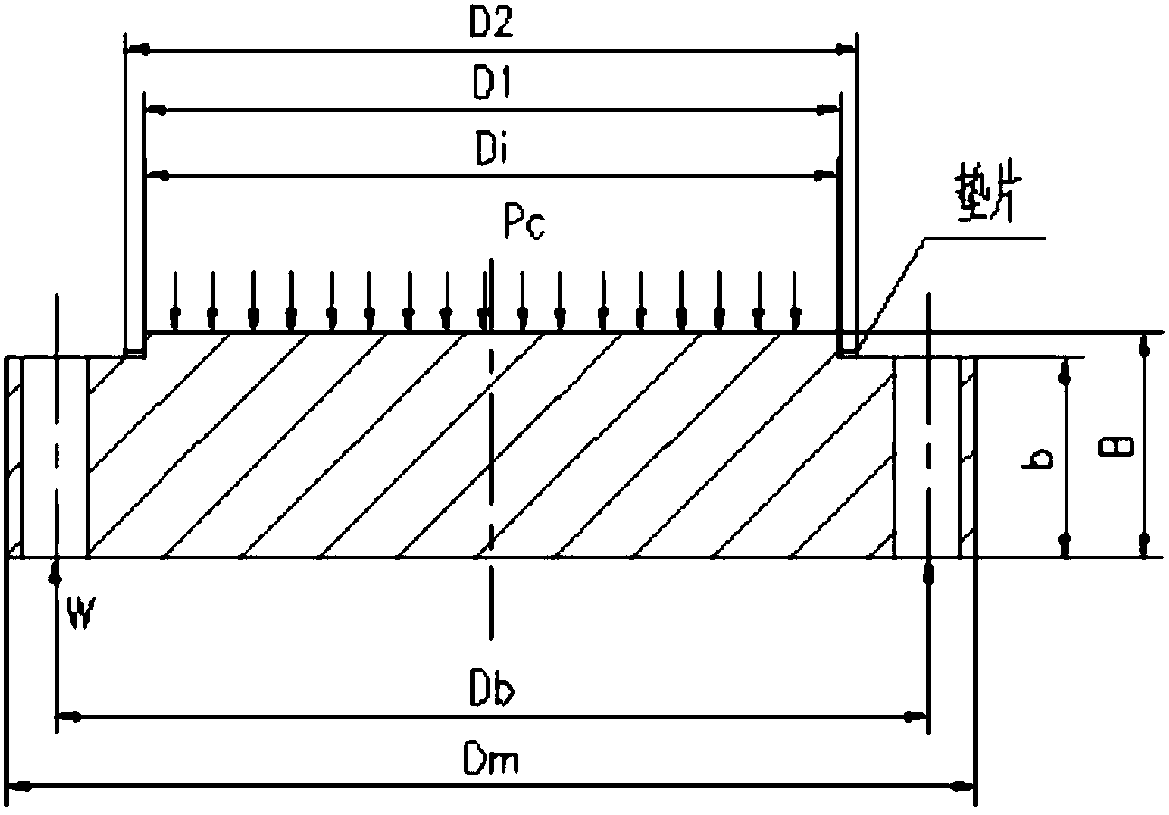

[0128] Specific implementation mode 2: A design method for a back pressure flat cover in this implementation mode, the description is attached Figure 4 It is a high-pressure accumulator product of a certain cubic meter, the design conditions: the design calculation pressure is 33MPa, the design temperature is 70°C, the material of the flat cover is 20MnMoIII, and the allowable stress of the material at the design temperature is 196MPa (according to GB150.2)),

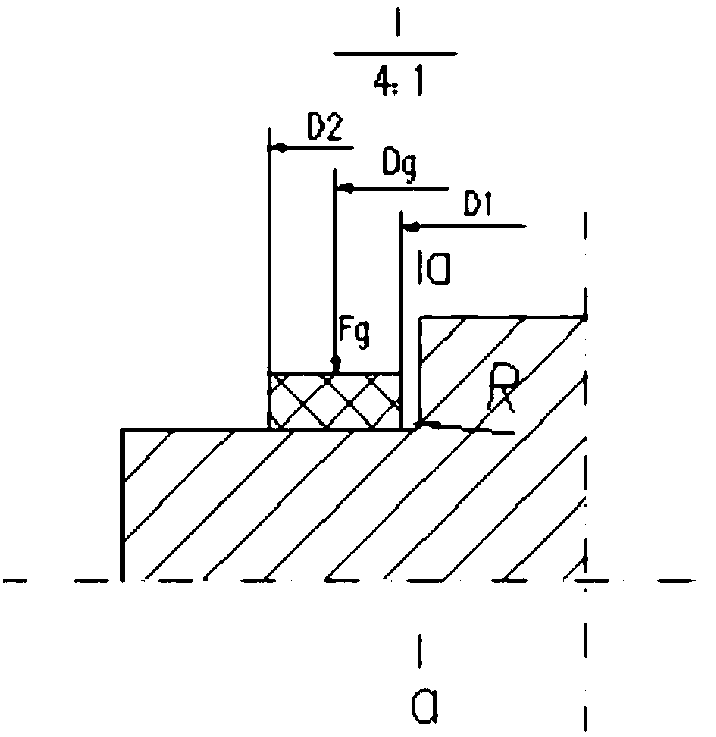

[0129] Among them, the size of the sealing pure copper gasket: D2 is Φ430mm, D1 is Φ410mm, the thickness δ is 5mm, flat cover, the specific size is detailed in the appendix of the manual Figure 5 ;

[0130] 1. According to the design method of the pressure vessel design standard GB150.3 flange, the diameter Dg of the center circle of the gasket pressing force is obtained;

[0131] Gasket contact surface width N=(430-410) / 2=10mm;

[0132] Gasket basic sealing width b0=N / 2=10 / 2=5mm;

[0133] Gasket effective sealing ...

specific Embodiment approach 3

[0165] Specific implementation mode three: a method for designing a back pressure-bearing flat cover according to this implementation mode,

[0166] Structural numerical method verification, combined with the calculation results of the second embodiment, applies the finite element method to calculate the load of the structure, obtains the stress value of the structure, and uses the stress classification method to perform safety assessment to verify the correctness of the above calculation results.

[0167] 1. Input conditions

[0168] The structure size is attached according to the manual Figure 5 , the calculated pressure and the maximum working pressure are both 33MPa, the design temperature is 70 ℃, the gasket material is pure copper, and the elastic modulus of the material at the design temperature is:

[0169]

[0170] The finite element method application program is ANSYS15.0, the calculation model is a plane axisymmetric body element, the element type is PLANE183, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com