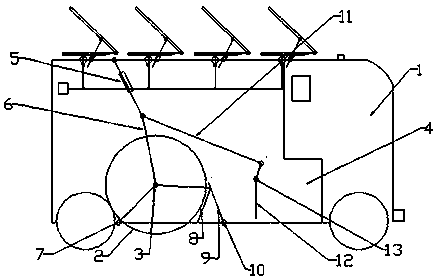

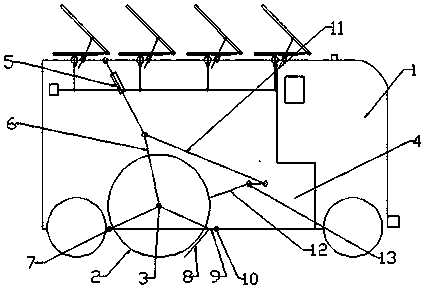

Solar sweeper garbage compression device

A garbage compression and cleaning vehicle technology, which is applied in the field of cleaning vehicles, can solve the problems of reducing the working efficiency of the cleaning vehicle, not having the function of garbage compression, and it is difficult to empty the garbage, so as to reduce the transition time, reduce the volume of garbage, and improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The working principle and working process of the present invention are as follows: when the solar sweeping vehicle 1 is working, the solar sweeping vehicle 1 moves forward, and the roller brush 2 rotates around the roller brush central axis 3, the direction of rotation is opposite to that of the wheels, and the road garbage is swept into the 4 In the garbage bin, after the garbage bin 4 is full of light and bulky garbage, the electric push rod 5 lifts the roller brush lifting rod 6 upwards, and the roller brush 2 rotates around the roller brush lifting shaft 7 and lifts it upwards, driving the collecting shovel 8 upwards. Movement, lift up the garbage baffle 9 and rotate around the garbage baffle shaft 10 to block the garbage in the garbage bin 4 from spilling, and at the same time, the electric push rod 5 drives the garbage compression plate pull rod 11 to rotate around the garbage compression plate axis 13 to drive garbage compression Plate 12 rotates around the rubbis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com