Novel trailing drilling platform

A drill floor, a new type of technology, is applied in the direction of earthwork drilling, drilling equipment, drilling equipment and methods, etc., and can solve the problems of in-place installation in difficult transition sites, heavy disassembly and assembly workload, and high transportation costs for drilling and workover operations. Achieve the effect of reducing operating costs and improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

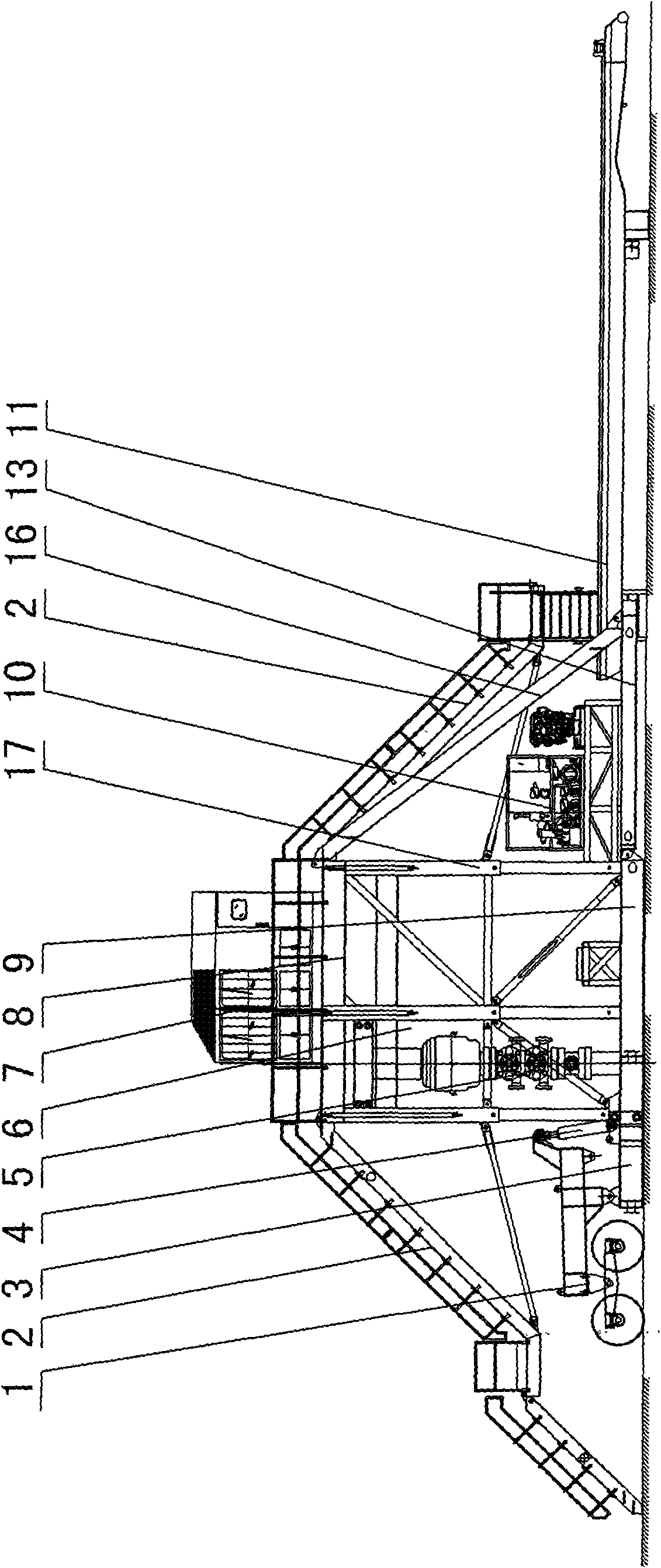

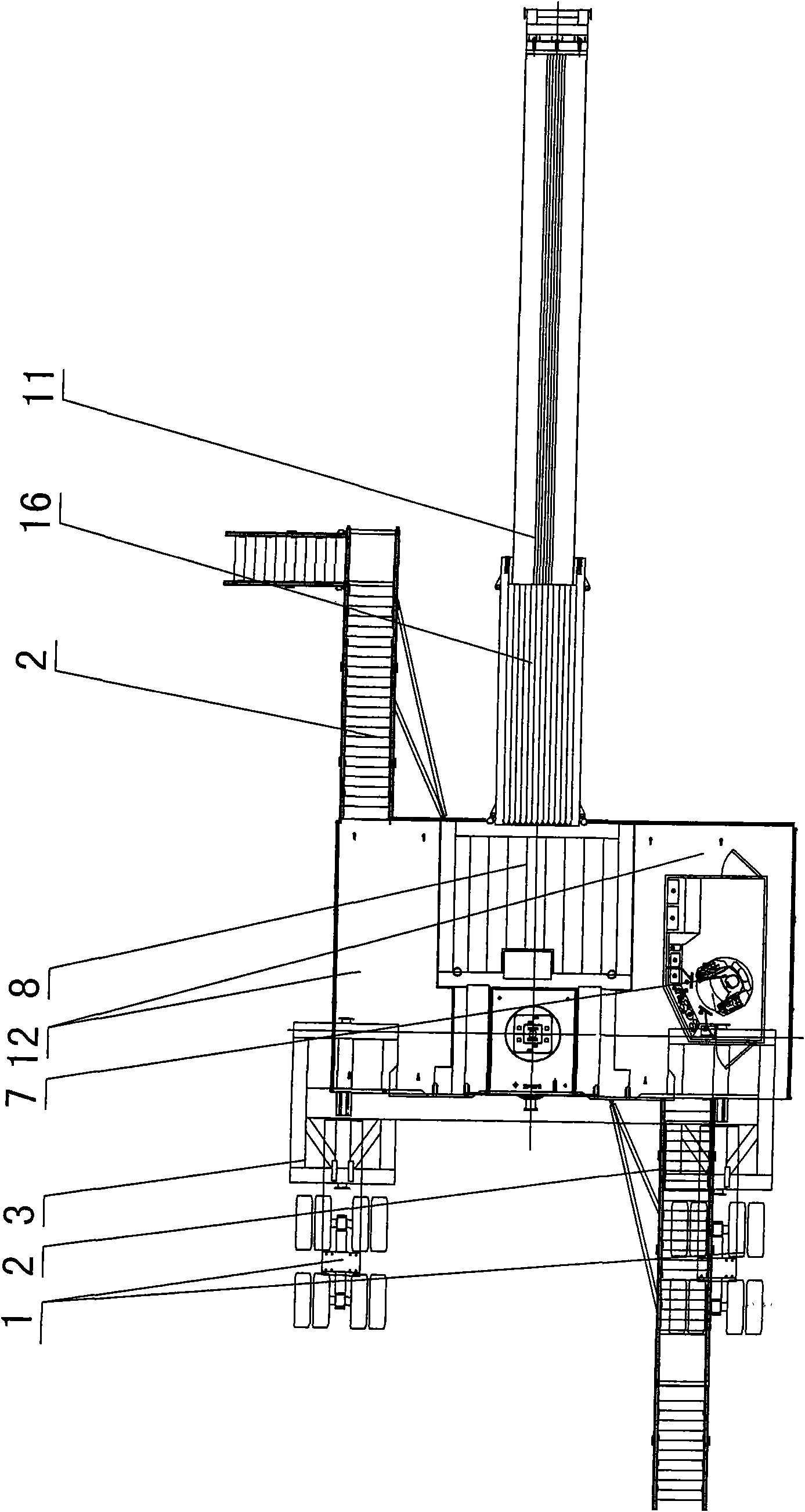

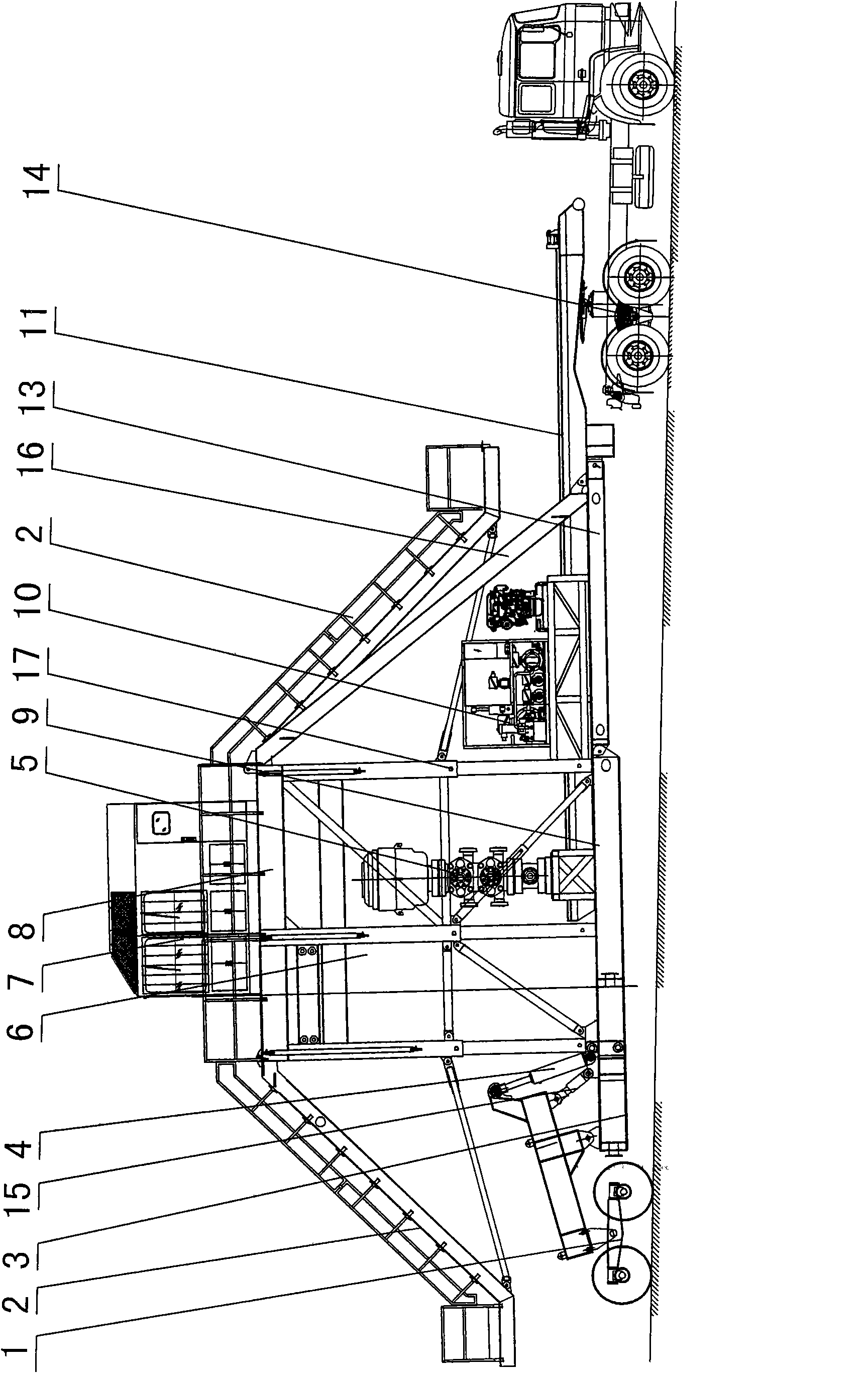

[0013] see figure 1 , figure 2 , the new trailer drill floor includes top assembly 8, bottom assembly 9, catwalk 11, connecting device 13, and the upright column 17 between the top assembly 8 and bottom assembly 9 is set together by a circular pipe and fixed by a pin It constitutes the main body of the drill floor, the top assembly 8 is connected with the sliding plate 16, the bottom assembly 9 is connected with the connecting device 13 through a pin shaft, the other end of the connecting device 13 is connected with the sliding plate 16, and the catwalk 11 is connected with the connecting device 13 through the connecting ear plate The ends are connected, the column 17, the slide plate 16, and the connecting device 13 form a triangular rigid frame structure, and the catwalk 11 is a steel frame structure welded by H-shaped steel, and the front part is equipped with a traction pin, which can slide on the surface of the connecting device 13 and shrink After returning to the dril...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com