Static pressure pile machine

A technology of static pile machine and pile pressing, which is applied in the direction of sheet pile wall, building, foundation structure engineering, etc. It can solve the problems of increasing the transition time and increasing the labor intensity of the operator, so as to reduce the labor intensity and shorten the transition time. Play time, improve the effect of economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

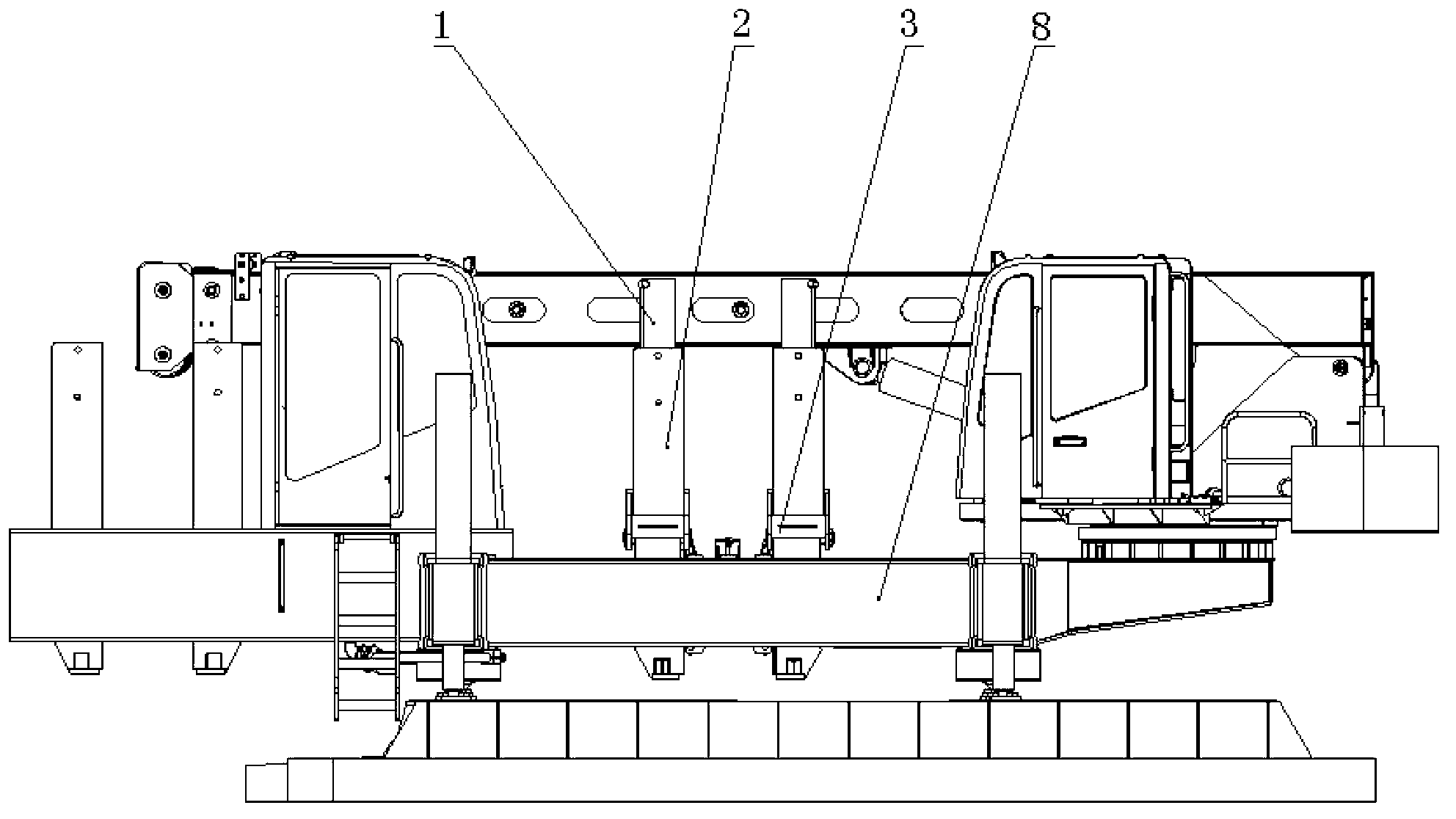

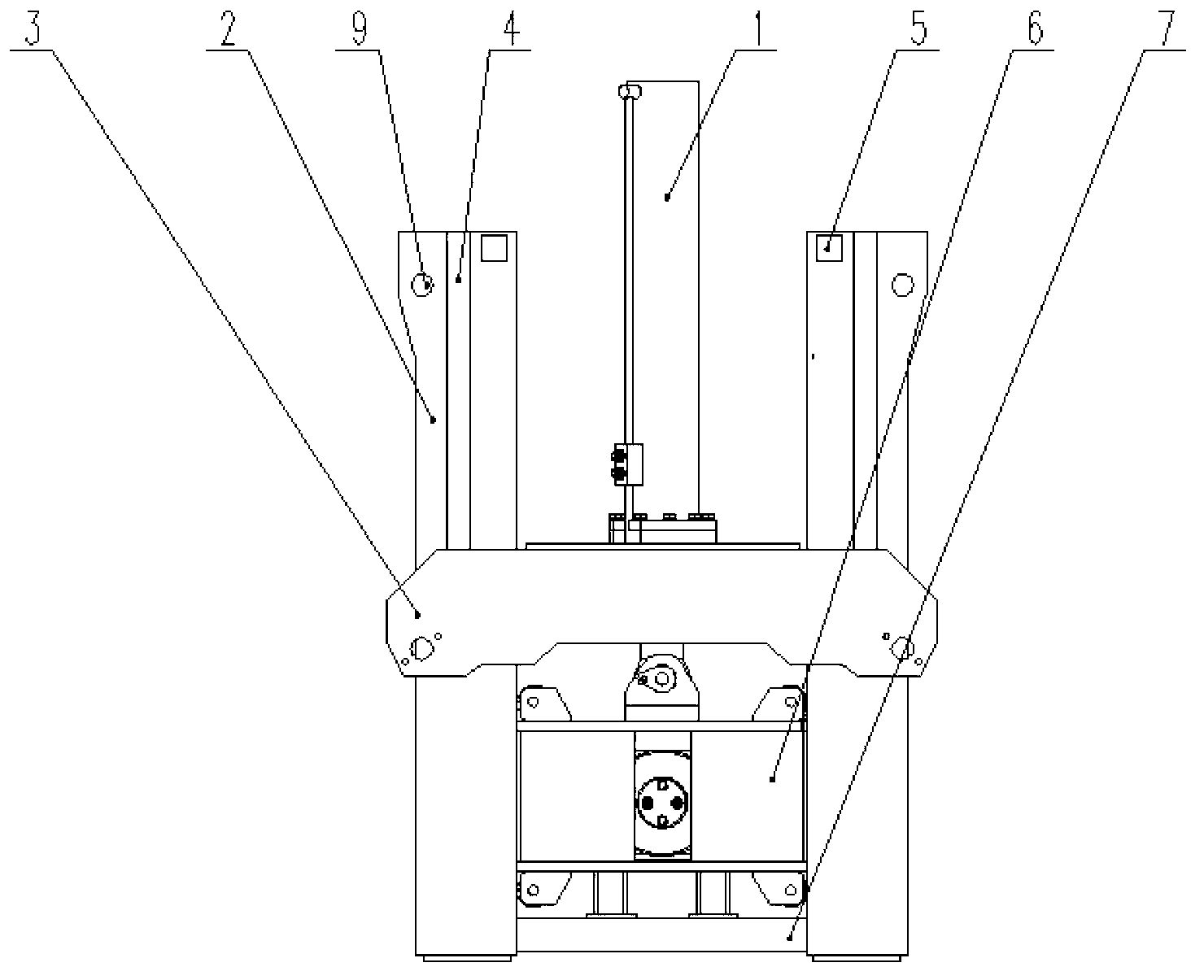

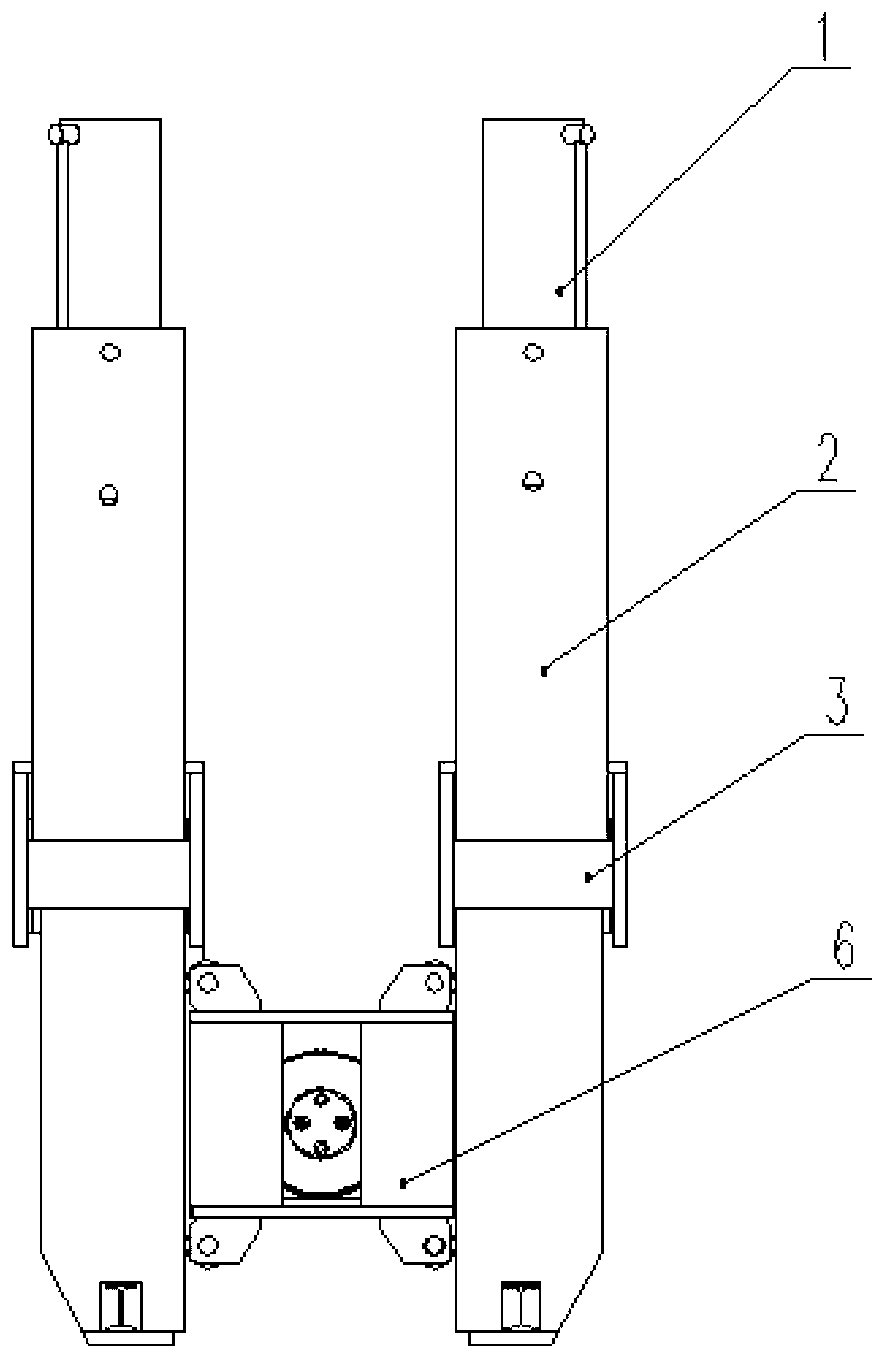

[0015] see figure 1 , figure 2 and image 3 , the fuselage 8 is provided with four columns 2 perpendicular to the fuselage 8, the bottom of the column 2 is provided with a connecting beam support 7, the column 2 is provided with a track 4, and the two ends of the piling table crossbeam 3 are respectively slidingly sleeved on the On the column 2, the beam 3 of the pile-pressing platform slides on the track 4, the upper end of the column 2 is provided with a positioning wedge 5, the cylinder body of the pile-pressing cylinder 1 is installed on the beam 3 of the pile-pressing platform, and the piston rod of the pile-pressing cylinder 1 is connected to There is a pile clamping box 6, a crossbeam installation hole is provided on the pile pressing platform beam 3, and a mounting hole is provided on the upper end of the column 2, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com