Lateral layout production flow line of box type steel structure element

A production line and assembly line technology, applied to other manufacturing equipment/tools, metal processing, manufacturing tools, etc., to achieve the effect of worker safety, shorten length and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

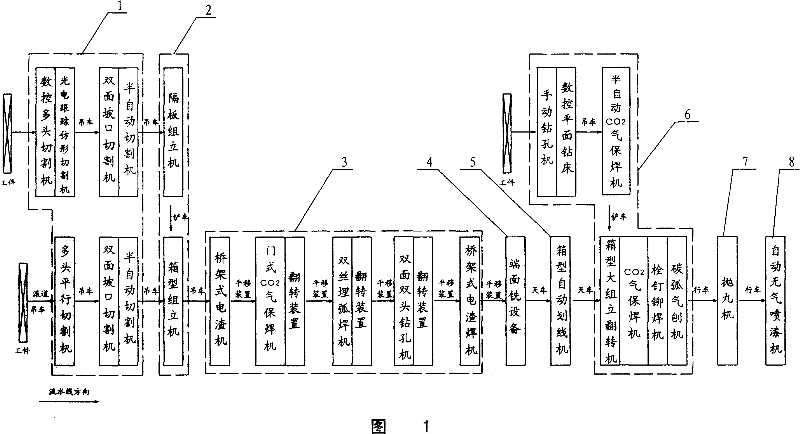

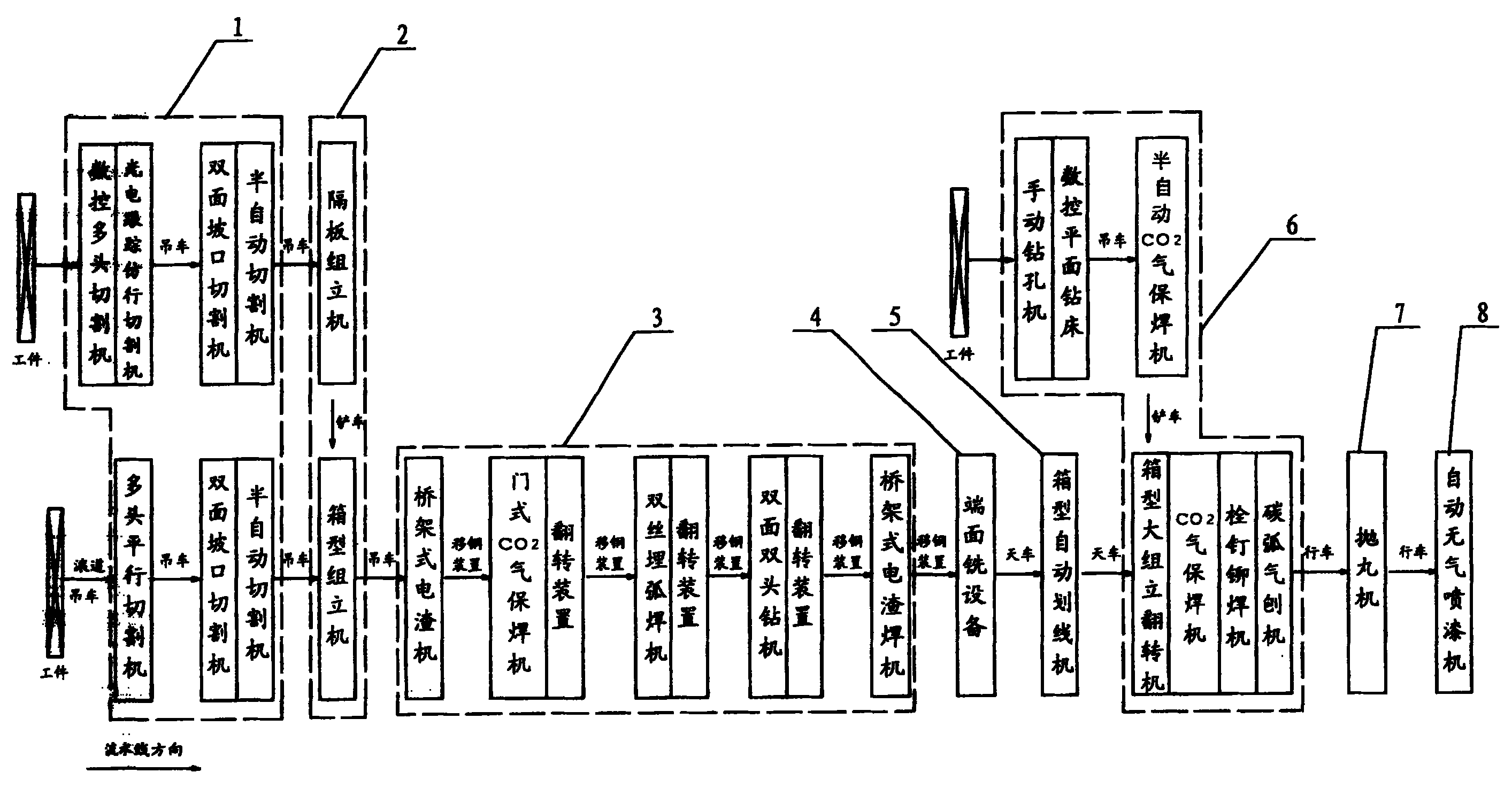

[0014] As shown in the figure, the horizontally arranged production line of box-shaped steel members of the present invention includes cutting equipment 1, assembly equipment 2, welding equipment 3, end face milling equipment 4, box-shaped automatic marking machine 5, Large group of welding equipment 6, shot blasting machine 7 and automatic airless paint spraying machine 8, the length direction of the workpiece is perpendicular to the direction of the production line; the working direction of all the equipment is perpendicular to the direction of the line. The cutting equipment 1 is composed of a multi-head parallel cutting machine, a numerical control multi-head cutting machine, a photoelectric tracking profiling cutting machine, a semi-automatic cutting machine and a double-sided bevel cutting machine. There is a raceway and a crane in front of the cutting equipment 1. The assembly equipment 2 is composed of a box-type assembly machine and a partition assembly machine, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com