Transfer device

A material transfer vehicle and driving device technology, applied in storage devices, transportation and packaging, etc., can solve the problems of inconvenient installation, low efficiency, time-consuming and labor-intensive, etc., and achieve the effect of simple structure, reasonable design and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

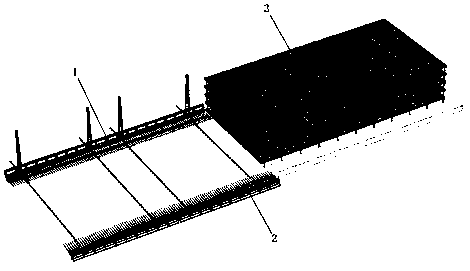

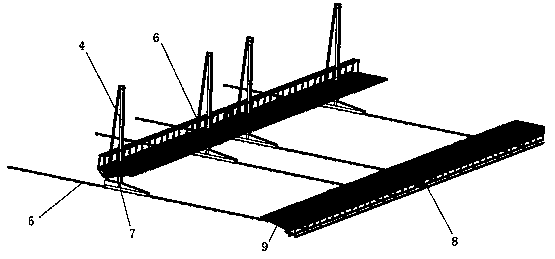

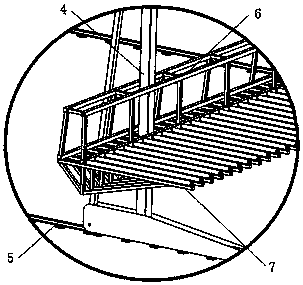

[0023] Such as Figure 1-4 , a kind of material transfer device, the material transfer device is cooperatingly arranged on one side of the storage wire frame, and it includes a material transfer car 1 and a foaming machine material transfer platform 2 arranged opposite to each other; the material transfer car 1 includes several vertically arranged vertical frame 4, several guide rails 5 arranged in parallel horizontally, and vertical slides 6, the vertical frame 4 corresponds to the guide rails 5 one by one, the vertical frame 4 is slidably installed on the guide rail, and moves along the direction of the guide rail, and the vertical slide frame 6 is slidably installed on the On the vertical frame, several vertical frames 4 jointly support the vertical slide frame 6, and the vertical slide frame 6 moves along the vertical direction on the vertical frame 4, and a plurality of first support horizontal frames 7 are horizontally and vertically arranged on one side of the vertical s...

specific Embodiment 2

[0024] Such as Figure 1-4 , on the basis of the specific embodiment 1, a sprocket is further set on the end of the roller on the first support horizontal frame 7 near the side of the vertical carriage 6, and the end of the roller on the second support horizontal frame 9 is fitted on the side close to the support platform 8 There is a sprocket, the sprocket and the main sprocket are connected by a chain, the main sprocket is set on the output shaft of the roller motor, and the roller motor is respectively installed on the platform bracket and the vertical carriage, and the electric control box is connected to the first driving device, the second The second driving device, the drum motor, the motor of the storage wire rack and the detection sensor, the detection sensor is respectively arranged at various parts of the material transfer vehicle, so as to facilitate the automatic operation of the material transfer device.

specific Embodiment 3

[0025] Such as Figure 1-4 , on the basis of the specific embodiment 1 or 2, the further described first driving device adopts a cylinder or a hydraulic cylinder or a motor to cooperate with rollers and guide rails; the second driving device adopts a servo motor and a sprocket chain arranged in cooperation with the servo motor Or rack and pinion form.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com