Mechanically followable oil cylinder

An oil cylinder and mechanical technology, which is applied in the field of mechanically followable oil cylinders, can solve the problems of easy damage of oil cylinders and hidden dangers of synchronous jacking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0091] The present invention is further illustrated below by means of examples, but the present invention is not limited thereto within the scope of examples.

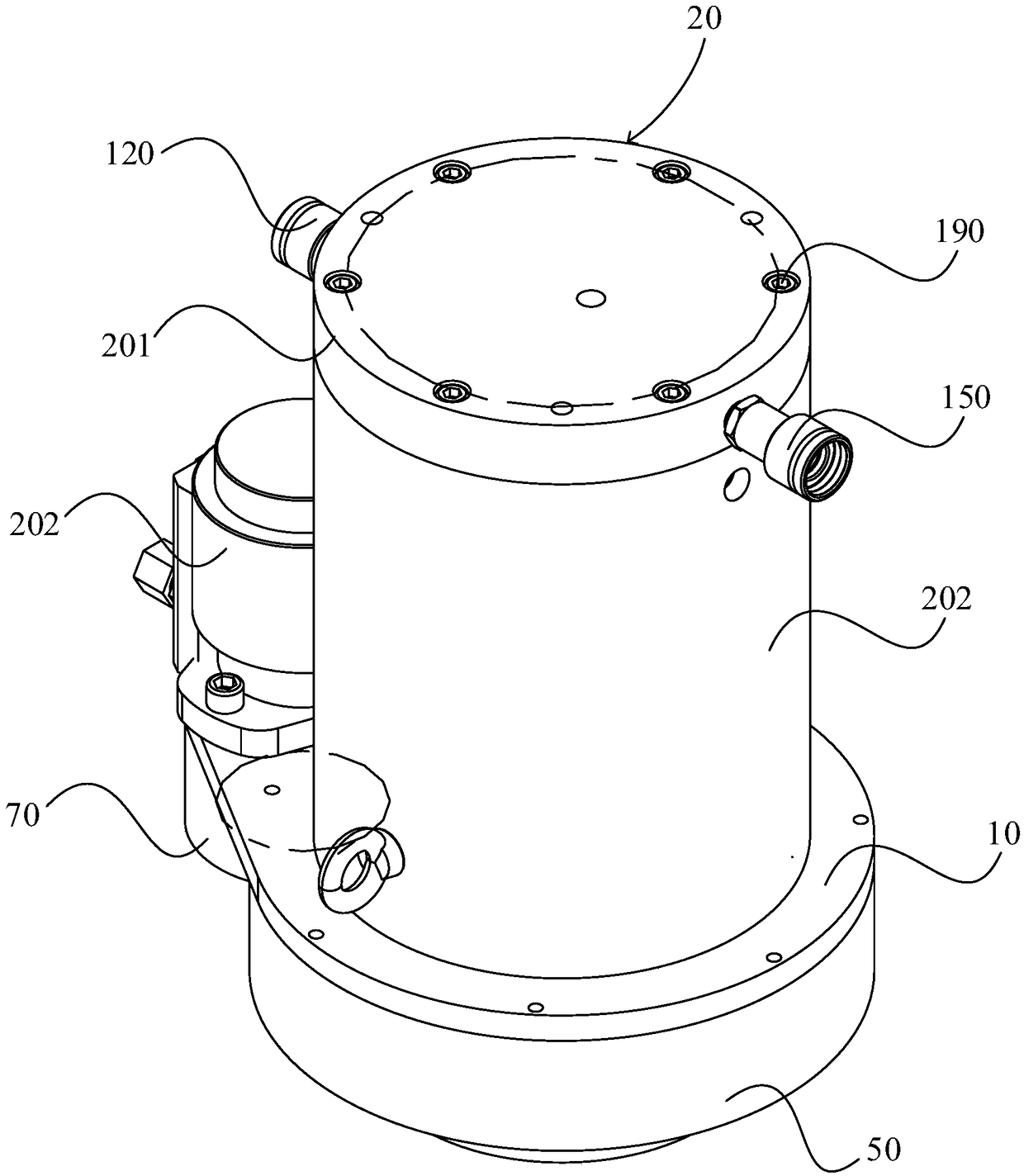

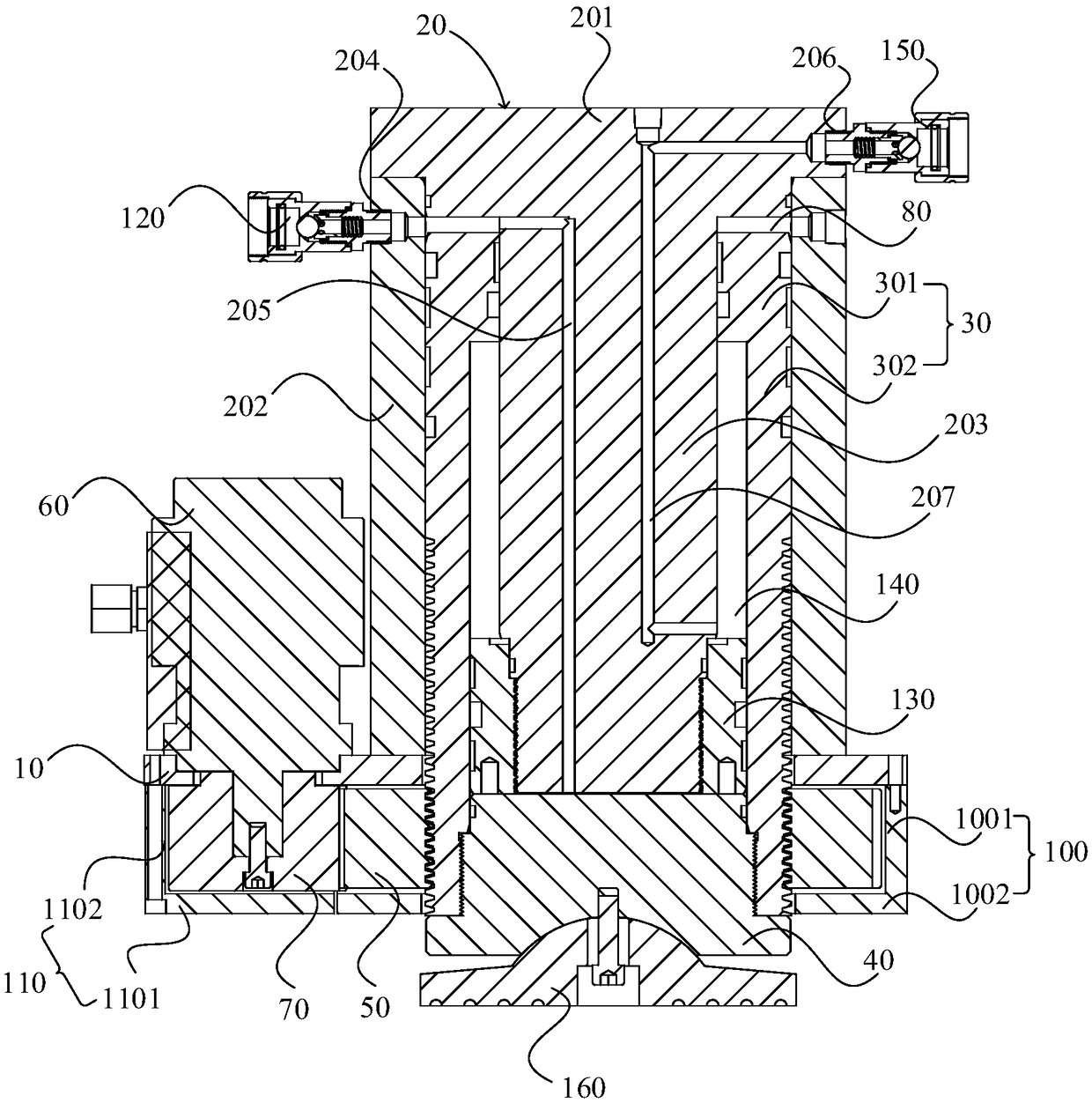

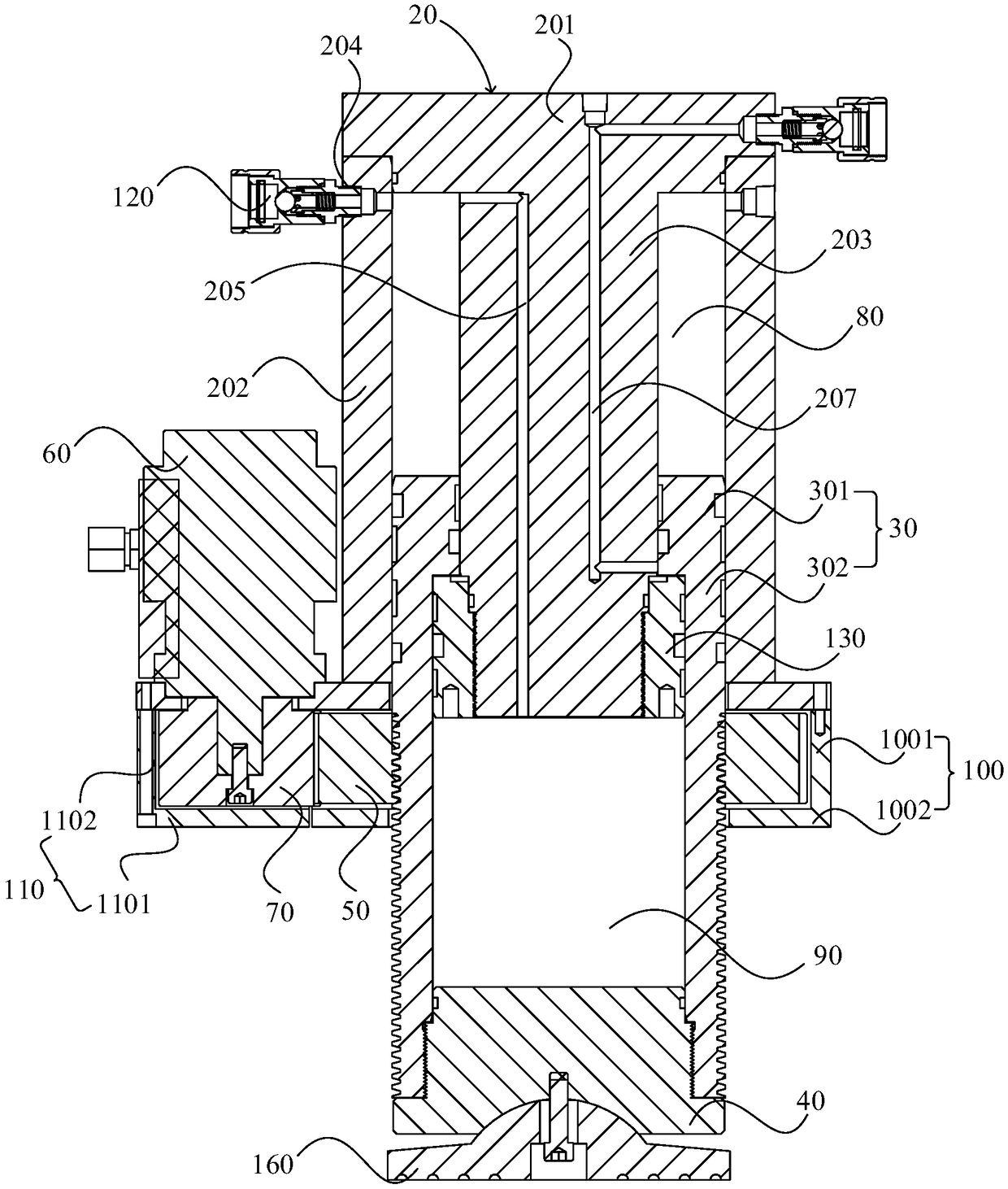

[0092] This embodiment discloses a mechanically followable oil cylinder, refer to Figure 1-6 It should be understood that the mechanically followable oil cylinder includes a support base 10 , a cylinder body 20 , a piston rod 30 , a pressure plate 40 , a self-locking nut 50 , a hydraulic motor 60 and a gear 70 . The cylinder body 20 is pressed on the support seat 10. The cylinder body 20 has a cylinder bottom 201, a side wall part 202 and an extension part 203. The extension part 203 extends from the cylinder bottom 201 along the height direction of the cylinder body 20. The extension part 203 and the side wall part A gap is formed between the inner walls of 202 , a first oil inlet 204 is provided on the side wall part 202 , and a first oil passage 205 is provided on the extension part 203 . The piston rod 30 is slee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com