Two-stage compression refrigeration system with expansion and pressurization

A refrigeration system and two-stage compression technology, which is applied to irreversible cycle compressors, compressors, refrigerators, etc., can solve the problems of low performance coefficient of single-stage compression refrigeration cycle, complex structure of refrigeration system, and high degree of wear of compressors. , to achieve the effect of simple structure, high system energy efficiency ratio and improved energy efficiency ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with specific embodiments.

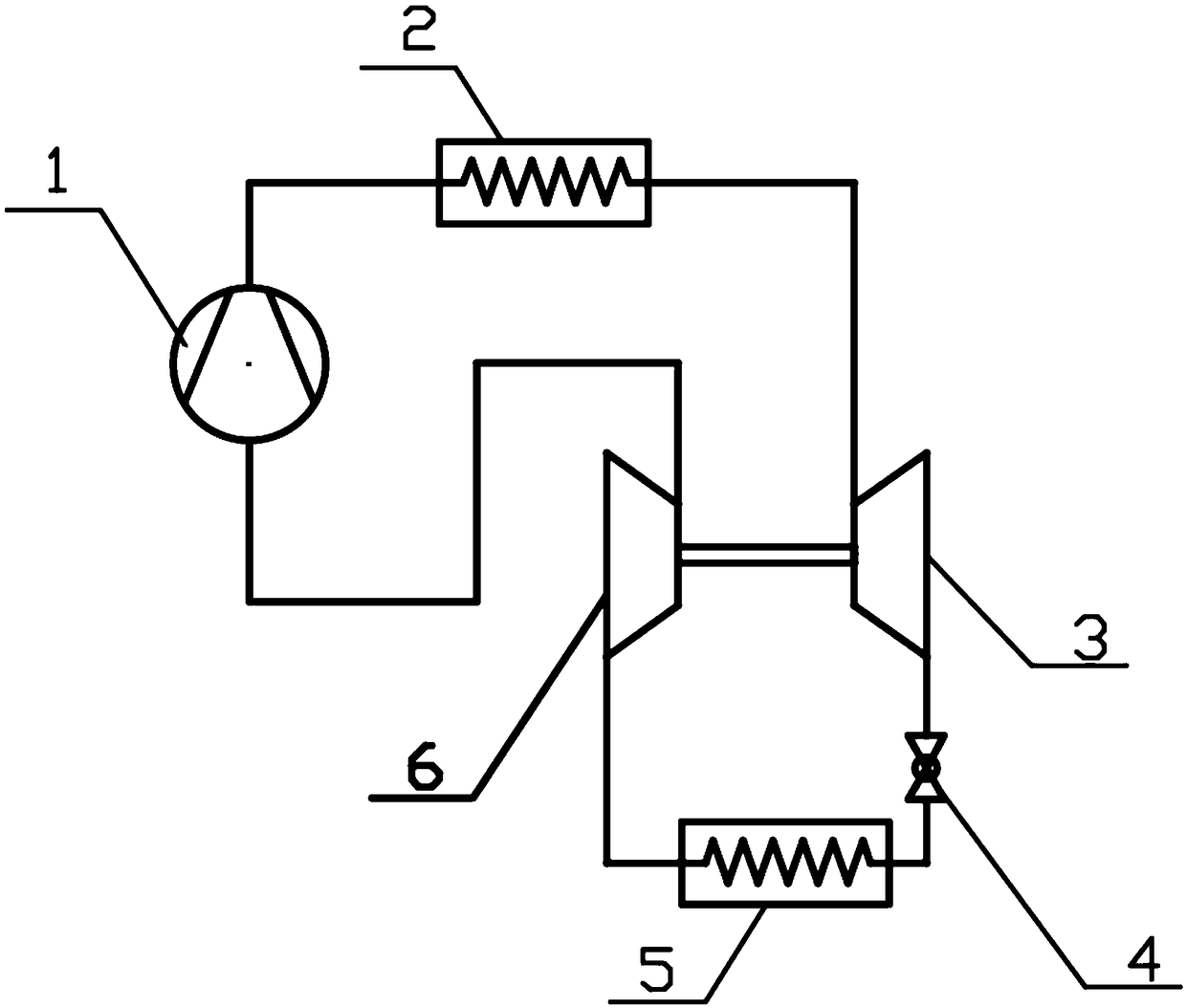

[0021] The principle diagram of a two-stage compression refrigeration system with expansion and boosting of the present invention is as follows figure 1 As shown, a functional compressor 1, a condenser 2, an expander 3, a throttling element 4, an evaporator 5, and a booster compressor 6 are included. The exhaust port of the functional compressor 1 is connected to the inlet of the condenser 2, the outlet of the condenser 2 is connected to the inlet end of the expander 3, and the outlet end of the expander 3 is connected to the joint The inlet end of the flow element 4 is connected, the outlet end of the throttle element 4 is connected with the inlet of the evaporator 5, the outlet of the evaporator 5 is connected with the suction port of the booster compressor 6, and the The discharge port of the booster compressor 6 is connected to the suction port of the functional compresso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com