Full-function trolley electrical control system and control method based on lifting trolley

An electrical control system and hoisting trolley technology, applied in the directions of load hanging components, transportation and packaging, can solve the problems of prolonged working cycle, decreased production efficiency, and the inability of drivers to pick up and unload goods immediately. Lifting load stability, reducing initial swing, reducing swing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

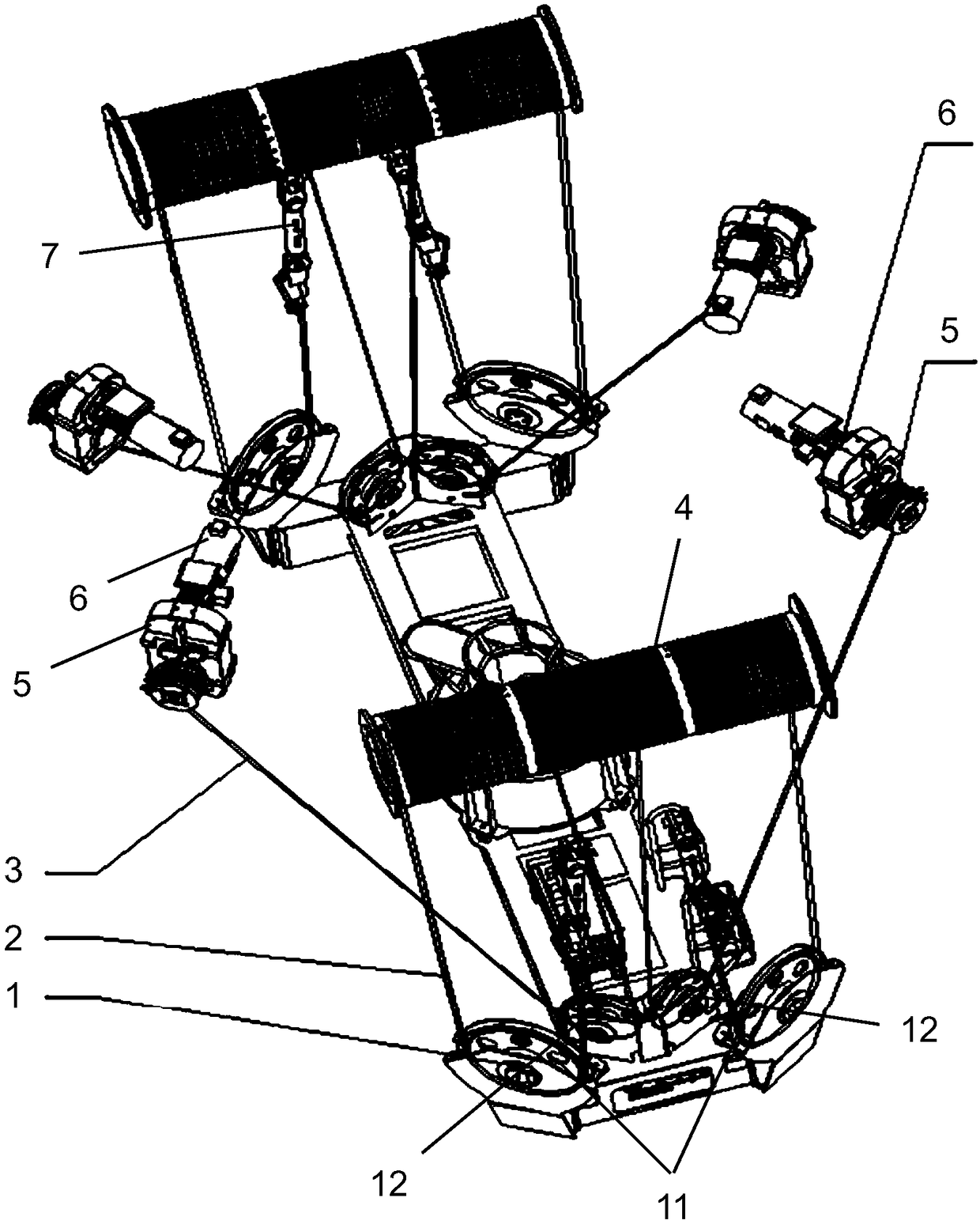

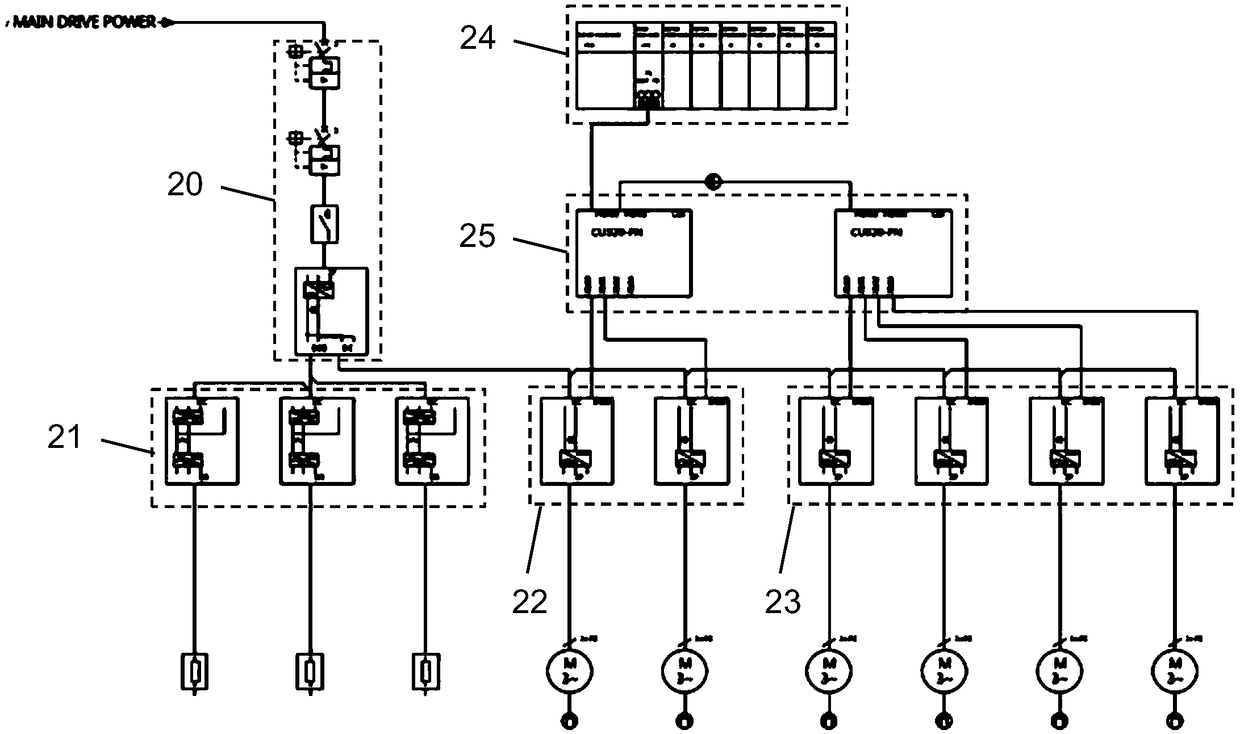

[0022] Please combine Figure 1 to Figure 2 As shown, a full-featured trolley electrical control system based on a lifting trolley provided by the present invention includes: a spreader body 1, and also includes: a pair of reel lifters symmetrically arranged above the two ends of the spreader body 1. lifting mechanism, 4 sets of three-in-one auxiliary anti-sway reel mechanisms respectively arranged above the four corners of the spreader body 1, and electronic control devices for controlling the reel lifting mechanism and four sets of three-in-one auxiliary anti-sway reel mechanisms mechanism.

[0023] Preferably, the lifting drum mechanism includes: a lifting rope 2 and a main drum 4, the main drum 4 is located above the end of the spreader body 1, and the lifting rope 2 is wound on the main drum 4 After the other end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com