A kind of optical lens detection equipment and detection method

A technology of optical lenses and testing equipment, applied in the testing of optical instruments, measuring devices, and testing of machine/structural components, etc., can solve the problems of inconvenient testing, affecting the laser testing accuracy, trouble, etc., and achieve convenient testing, stable fixing effect, good size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

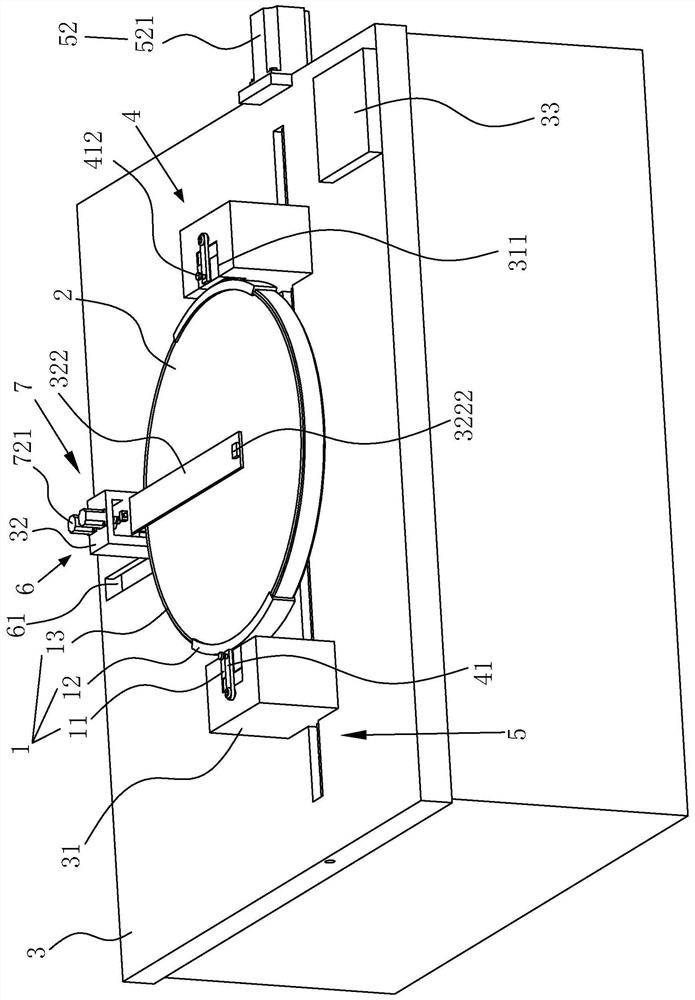

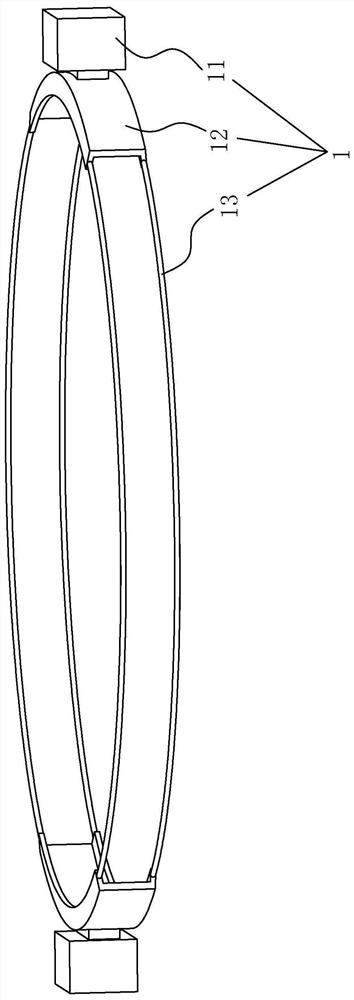

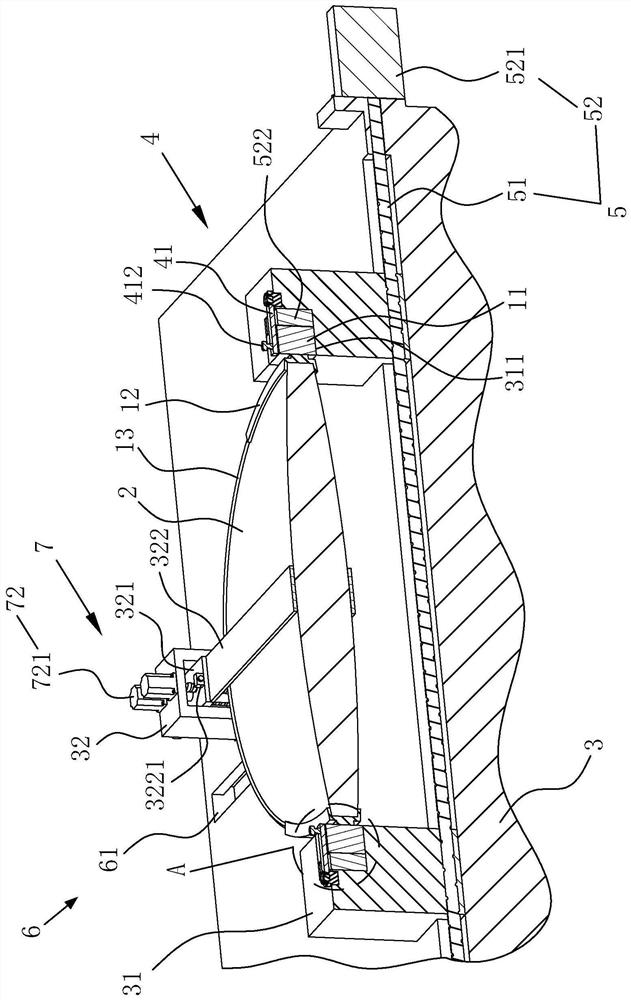

[0046] refer to figure 1 and 2 , is an optical lens inspection device disclosed in the present invention, which includes a horizontally arranged inspection frame 3 and a reference base 1 fixed to the lens 2 . The reference seat 1 includes positioning seats 11 symmetrically arranged on both sides of the lens 2 , and fitting strips 12 made of flexible rubber are fixed on opposite sides of the two positioning seats 11 . The length of the fitting strip 12 is greater than the length of the positioning seat 11, and the cross-sectional shape of the fitting strip 12 is a V shape opposite to the bending direction. When the fitting strip 12 abuts against the lens 2, the fitting strip 12 is in a deformed state. Elastic cords 13 are arranged between the fitting strips 12 for connecting the opposite ends of the two fitting strips 12 , the number of the elastic cords 13 is four and a group of two is used. Two sets of elastic cords 13 are respectively arranged beside the two ends of the fi...

Embodiment 2

[0058] A method for detecting an optical lens disclosed by the present invention comprises the following steps:

[0059] Step 1: Manually fit the lens and the fitting strip so that the two positioning seats are symmetrically fixed on both ends of the lens in the radial direction;

[0060] Step 2: Fit the positioning seat into the positioning groove, drive the support frames to slide close to each other through the sliding mechanism to clamp the positioning seat and the lens horizontally, and fix the positioning seat vertically in the positioning groove through the fixing parts;

[0061] Step 3: Drive the offset frame to slide horizontally through the offset mechanism until the vertical projection of the metal sheet on the lens coincides with the center of the lens;

[0062] Step 4: Drive the two metal sheets vertically close to each other and slide to fit the lens through the bonding mechanism, and judge whether the metal sheet is at the lowest level with the lens by whether t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com