Speed stabilizing mechanism for control valve and pressure feed type speed stabilizing valve

A technology for controlling valves and stabilizing speed, which is applied in the direction of multi-way valves, valve devices, mechanical equipment, etc., which can solve the problems of low efficiency and cumbersome operation, and achieve the effect of efficient operation, stable operation and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Hereinafter, the present invention will be further described in detail with reference to the examples and drawings, but the implementation of the present invention is not limited thereto.

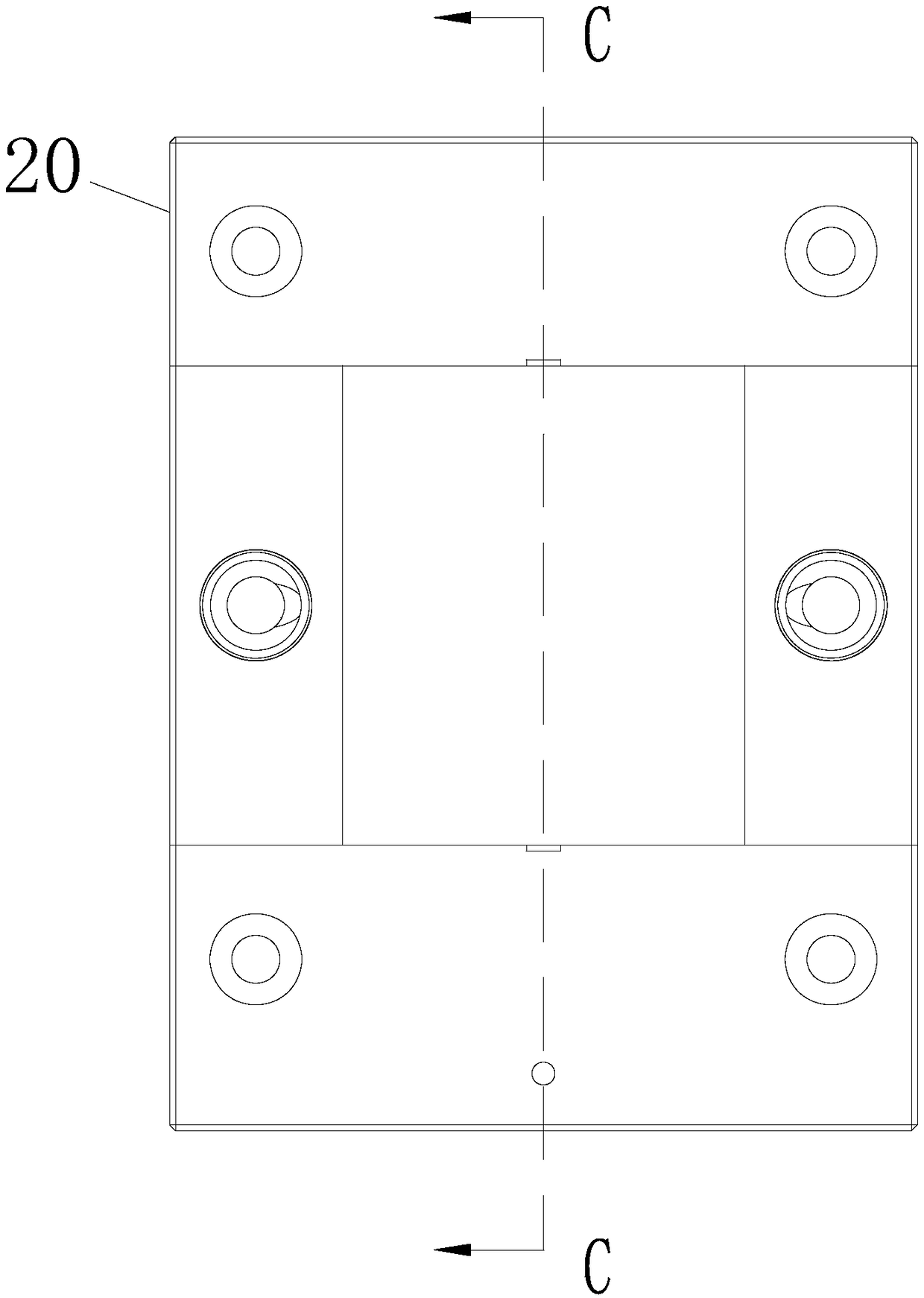

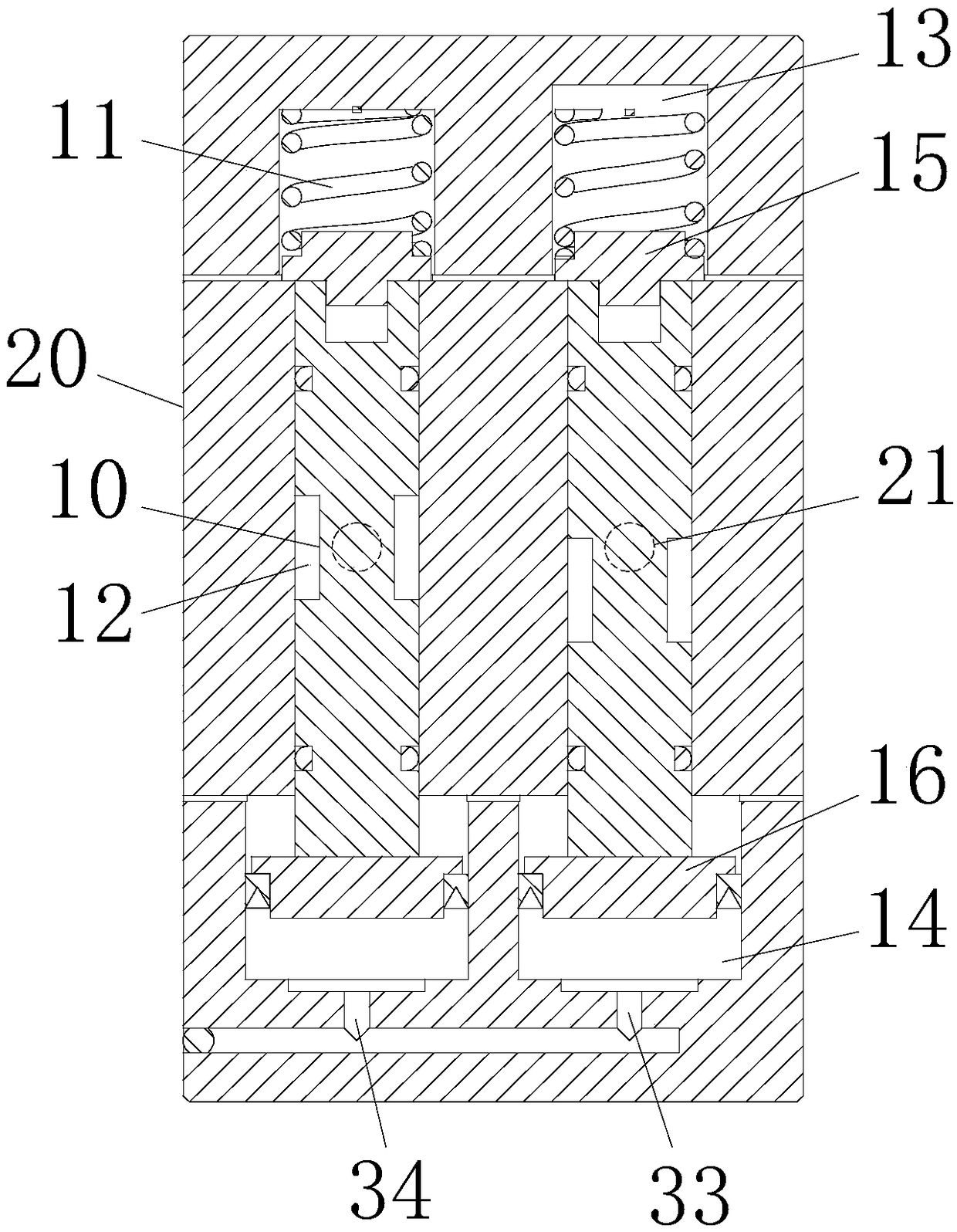

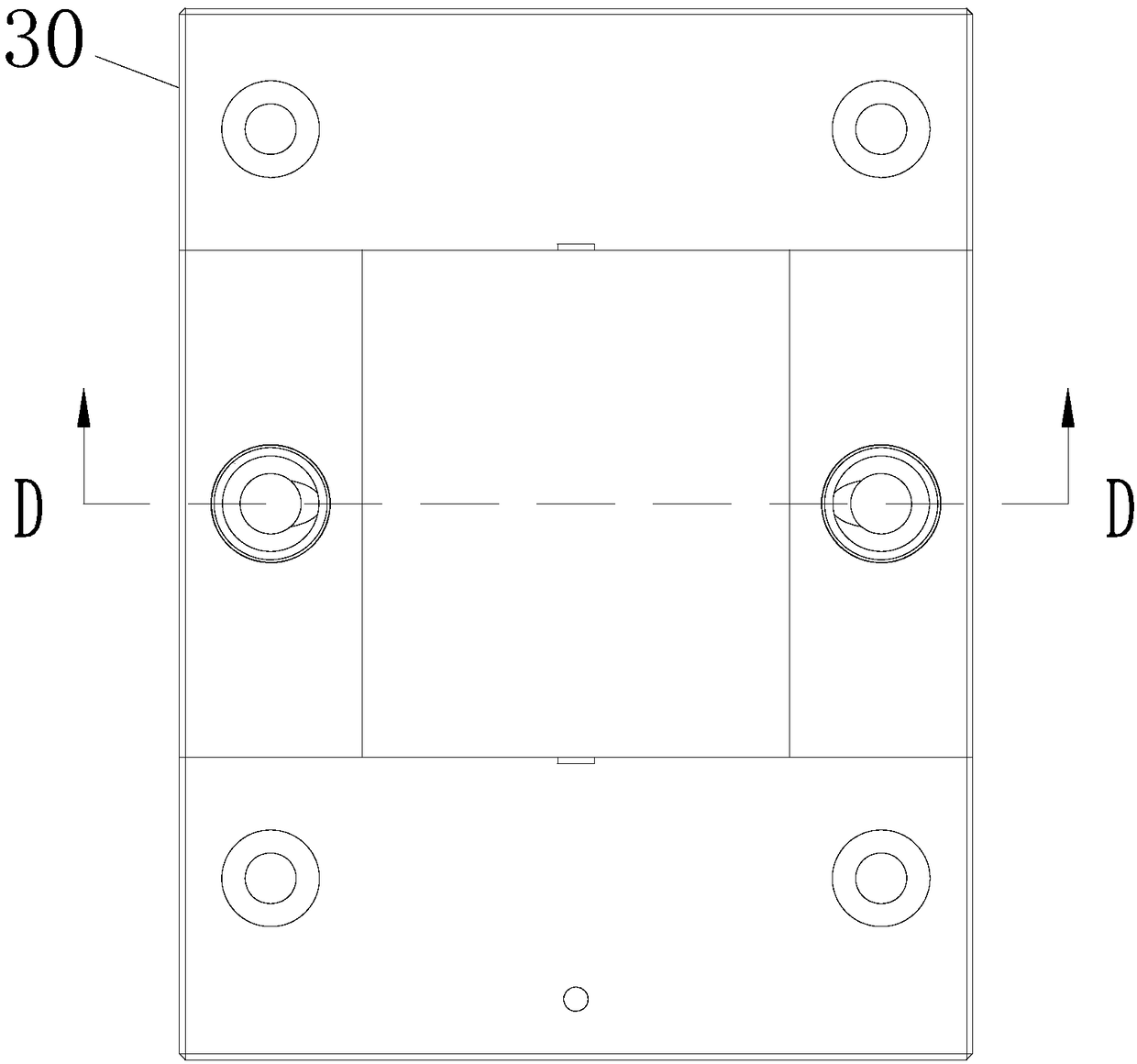

[0033] Such as figure 1 with figure 2 As shown, the speed stabilization mechanism of the control valve of this embodiment includes: a sliding valve core 10 and an elastic member 11, the elastic member 11 may be a spring; the sliding valve core 10 is disposed in the control valve 20 for controlling the control valve The opening degree of the flow passage 21, the sliding valve core 10 is provided with a valve port 12 corresponding to the position of the control valve flow passage 21. Specifically, the axis of the sliding valve core 10 intersects the axis of the control valve flow passage 21, and the valve port 12 is located At the intersection of the sliding valve core 10 and the control valve flow passage 21, a spring can be arranged at the upper end of the sliding valve core 10 to push ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com