Oil-water separator for petroleum refining

A technology of oil-water separator and petroleum, which is applied in the direction of liquid separation, separation method, liquid separation through thermal diffusion, etc., and can solve the problems of oily sewage separation, limited capacity of slag removal hopper, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

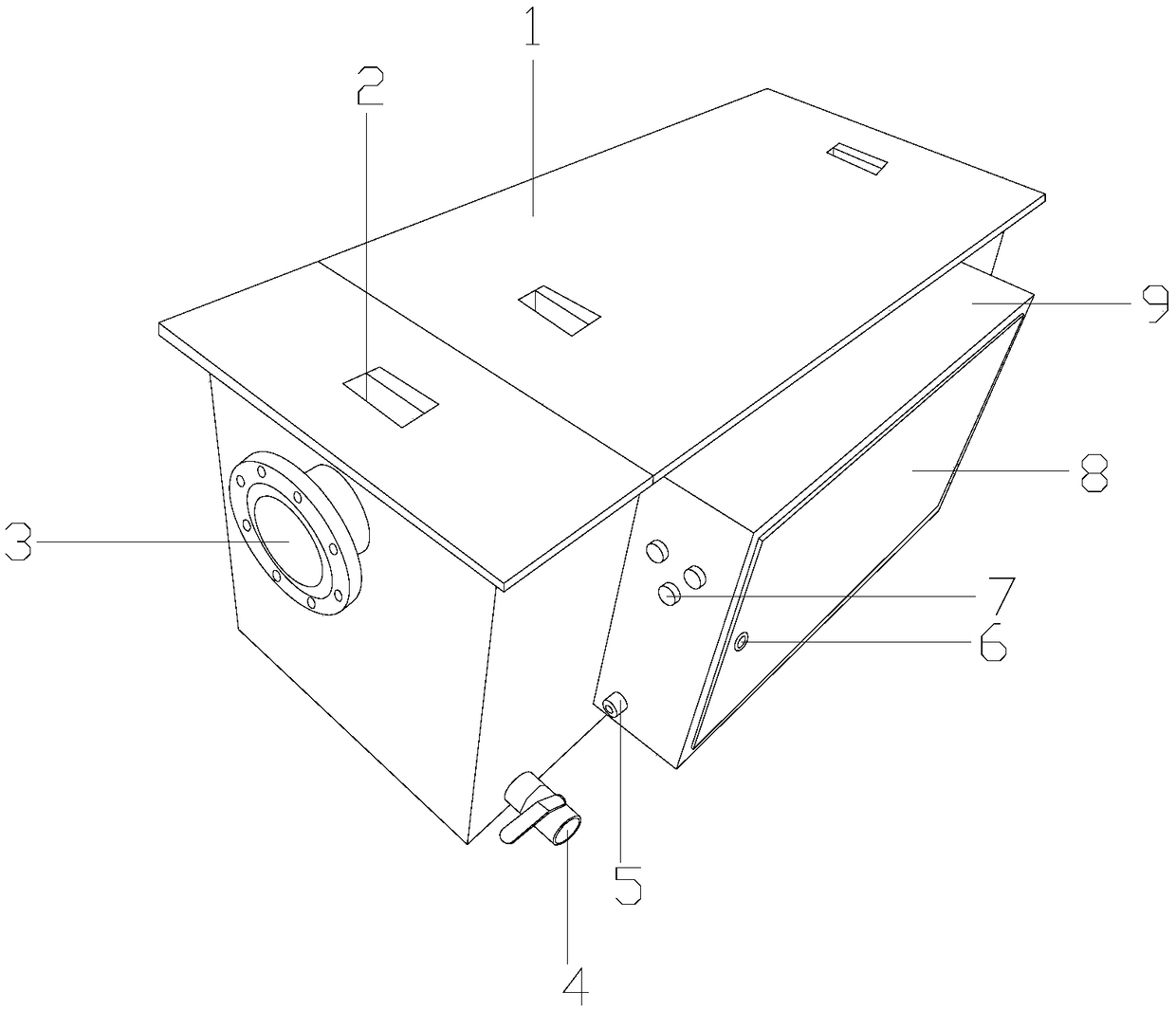

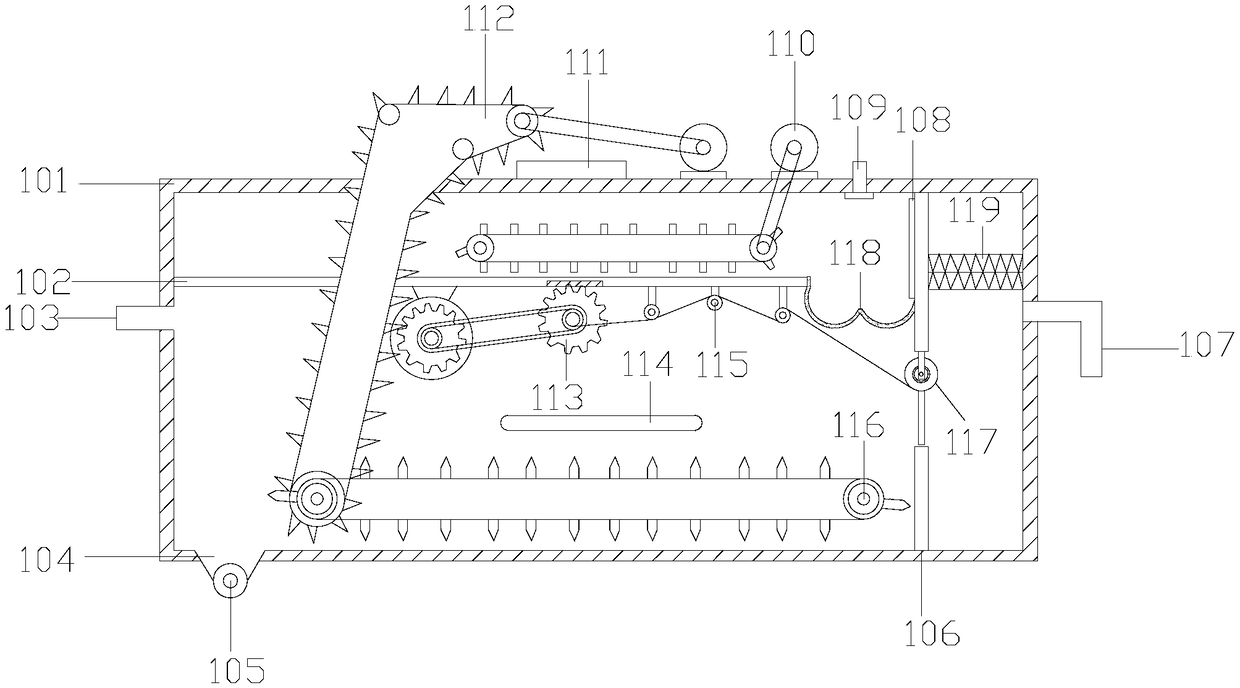

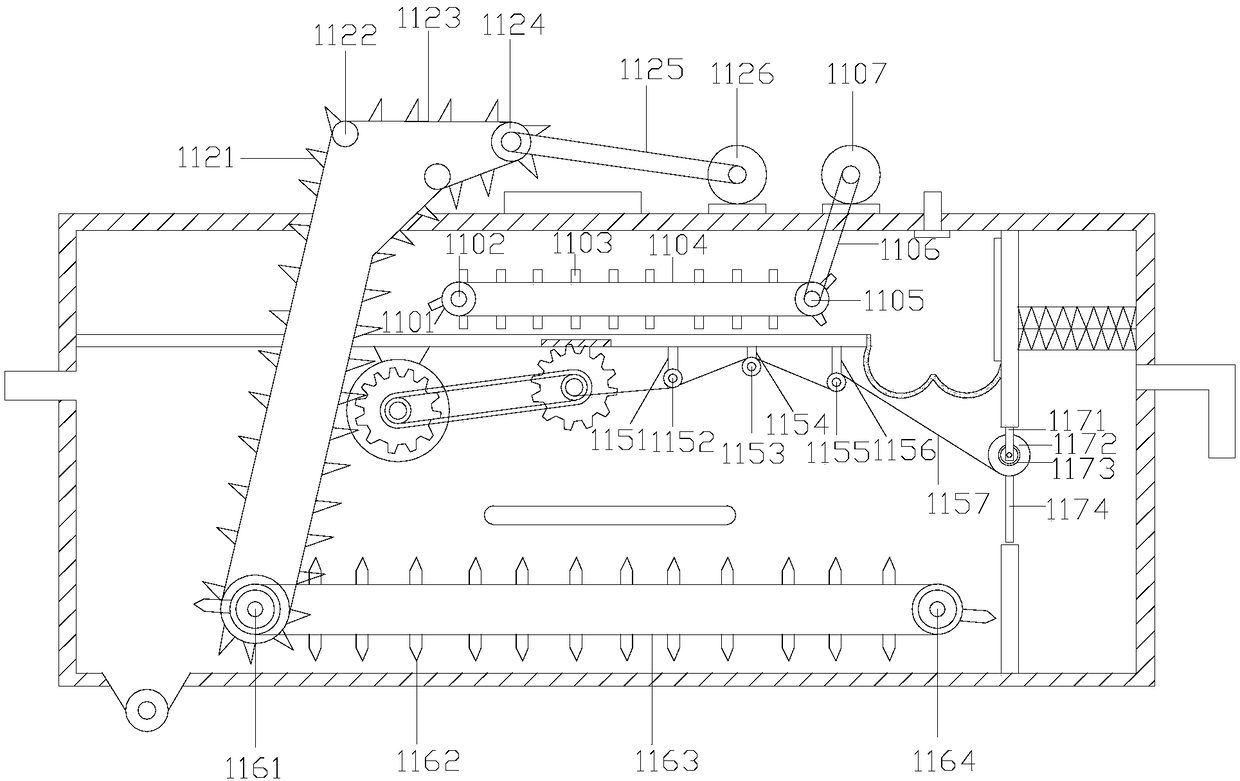

[0022] see Figure 1-Figure 4, the present invention provides a technical scheme of an oil-water separator for petroleum refining: its structure includes an automatic cleaning mechanism 1, a handle 2, a water inlet flange 3, a sewage discharge port 4, a drain port 5, a door lock 6, a control Switch 7, box door 8, power storage box 9, the upper end of the automatic cleaning mechanism 1 is fixed with more than two handles 2, and is an integrated structure, the water inlet flange 3 is fixedly welded to the automatic cleaning mechanism The left side of the pollution mechanism 1, and the inside of the two are connected. The electric storage box 9 is fixedly welded to the front end of the automatic cleaning mechanism 1, and is connected by bolt reinforc...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap