Integrated milling structure and method for working edge and rail top surface of turnout switch rail

A working edge and tip rail technology, applied in milling cutters, manufacturing tools, milling machine equipment, etc., can solve problems such as affecting the wheel-rail relationship, affecting the comfort of trains crossing the switch and the service life of the switch.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

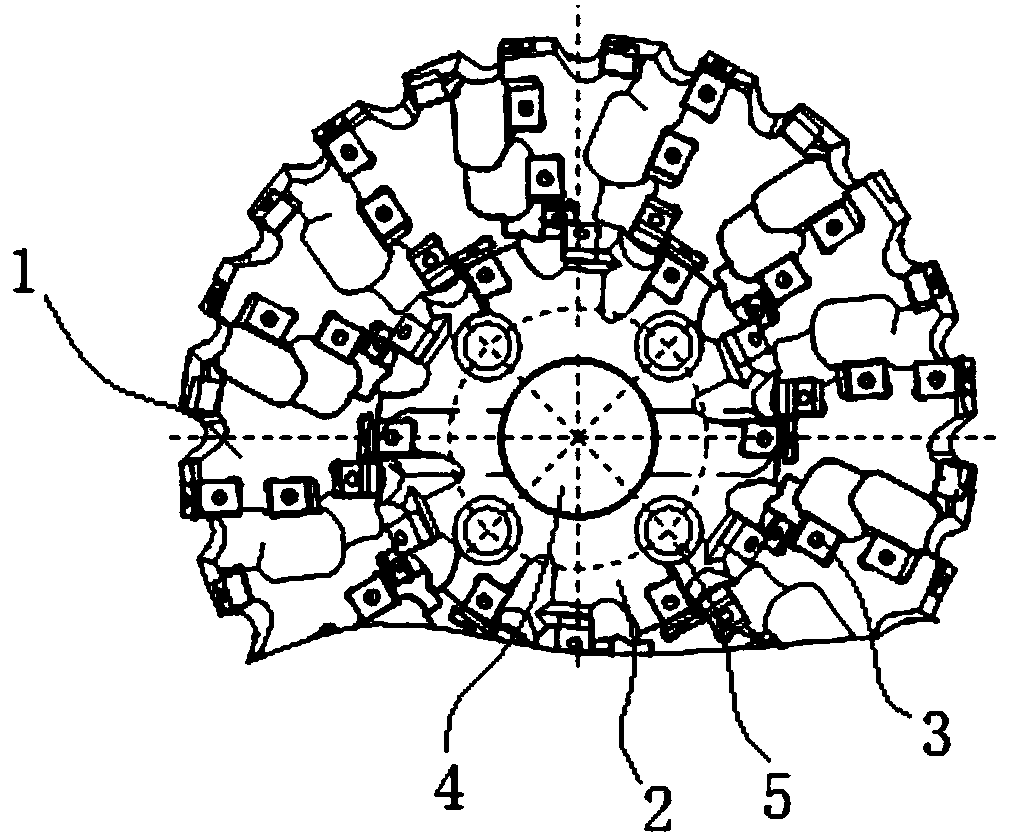

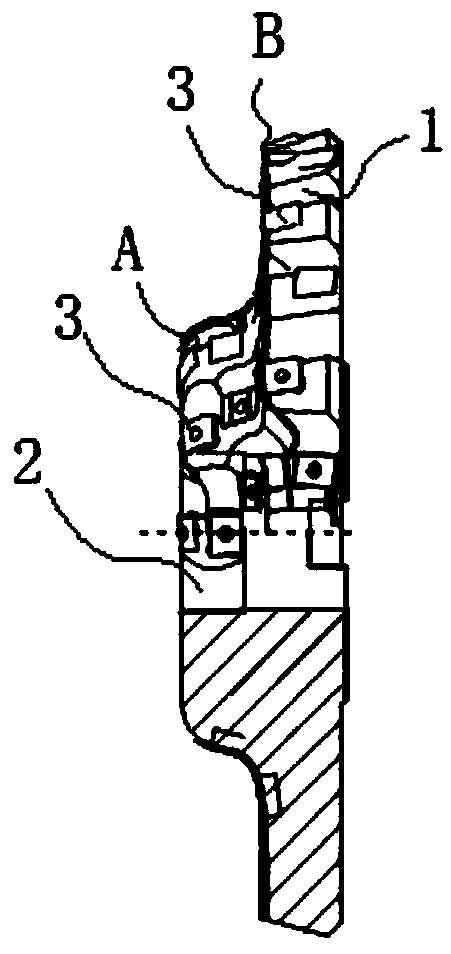

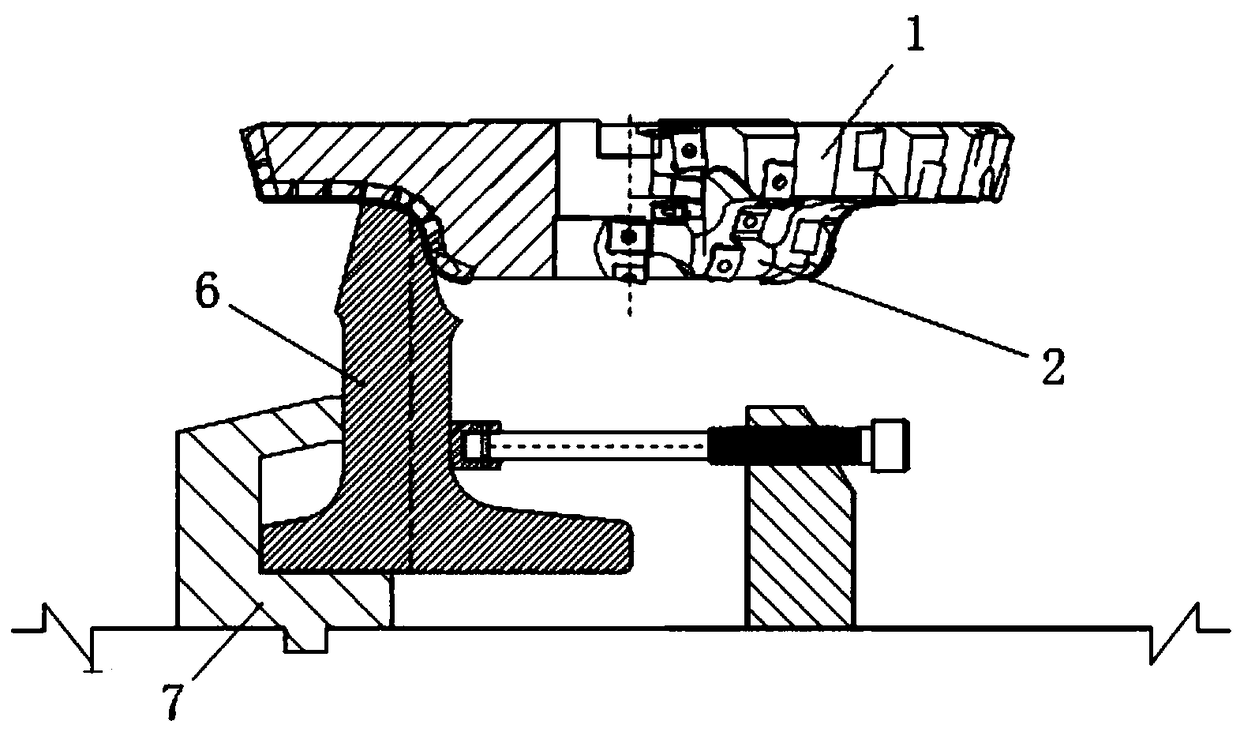

[0028] see figure 1 , figure 2 , image 3 , is an integrated milling structure of the working edge and rail top surface of a turnout tip rail provided by the embodiment of the present invention, such as figure 1 , figure 2 , image 3 As shown, the structure includes a milling cutter body, the milling cutter body includes a first cutter body part 1 and a second cutter body part 2, and the second cutter body part 1 protrudes from the first cutter body part 2 side; the first cutter body part 1 and the second cutter body part 2 both have a disc-shaped structure; the diameter of the first cutter body part 1 is larger than the diameter of the second cutter body part 2;

[0029] A plurality of milling cutter blades 3, the plurality of milling cutter blades 3 are respectively arranged in the blade mounting grooves on the milling cutter body 1;

[0030] Wherein, when the milling cutter body rotates for cutting, a plurality of the milling cutter inserts 3 form a smooth transition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com